No. 700 Portable Power Drive

4.Rotate cam plate to original position and replace stop screw.

NOTE! If it becomes necessary to remove or replace the guide block, the stamped number

Threading With Geared Threaders

![]() WARNING

WARNING

When threading pipe up to 5″ nominal, the 450

Tristand Vise can be used. However, when thread- ing 6″ nominal pipe, a

Bench Chain Vise or a 460 Tristand Vise must be used.

1. Position pipe to be threaded securely in vise.

![]() WARNING To prevent tipping, long lengths of pipe should also be supported with a pipe stand. Vise and stands should be on level ground.

WARNING To prevent tipping, long lengths of pipe should also be supported with a pipe stand. Vise and stands should be on level ground.

2.Install the No. 774 Square Drive Adapter in the Power Drive, spline end first, until the

NOTE! Installation can be made from either side of the Power Drive.

3.Adjust Geared Threader for size of pipe to be thread- ed (Refer to previous instructions). Using two persons, pick up threader and slide it onto the pipe. Carefully center the end of the pipe in the throats of the dies.

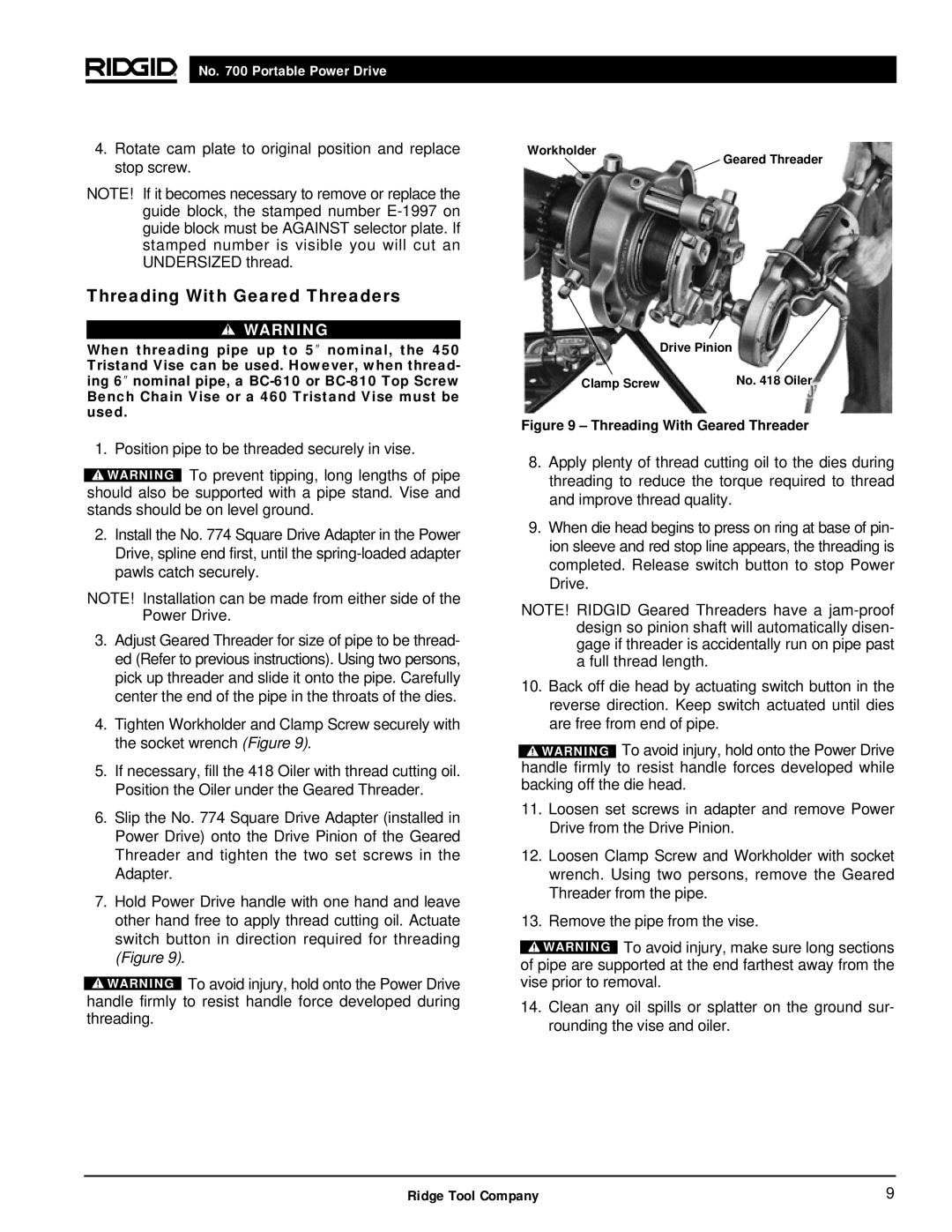

4.Tighten Workholder and Clamp Screw securely with the socket wrench (Figure 9).

5.If necessary, fill the 418 Oiler with thread cutting oil. Position the Oiler under the Geared Threader.

6.Slip the No. 774 Square Drive Adapter (installed in Power Drive) onto the Drive Pinion of the Geared Threader and tighten the two set screws in the Adapter.

7.Hold Power Drive handle with one hand and leave other hand free to apply thread cutting oil. Actuate switch button in direction required for threading (Figure 9).

![]() WARNING To avoid injury, hold onto the Power Drive handle firmly to resist handle force developed during threading.

WARNING To avoid injury, hold onto the Power Drive handle firmly to resist handle force developed during threading.

Workholder

Geared Threader

Drive Pinion

Clamp Screw | No. 418 Oiler |

Figure 9 – Threading With Geared Threader

8.Apply plenty of thread cutting oil to the dies during threading to reduce the torque required to thread and improve thread quality.

9.When die head begins to press on ring at base of pin- ion sleeve and red stop line appears, the threading is completed. Release switch button to stop Power Drive.

NOTE! RIDGID Geared Threaders have a

10.Back off die head by actuating switch button in the reverse direction. Keep switch actuated until dies are free from end of pipe.

![]() WARNING To avoid injury, hold onto the Power Drive handle firmly to resist handle forces developed while backing off the die head.

WARNING To avoid injury, hold onto the Power Drive handle firmly to resist handle forces developed while backing off the die head.

11.Loosen set screws in adapter and remove Power Drive from the Drive Pinion.

12.Loosen Clamp Screw and Workholder with socket wrench. Using two persons, remove the Geared Threader from the pipe.

13.Remove the pipe from the vise.

![]() WARNING To avoid injury, make sure long sections of pipe are supported at the end farthest away from the vise prior to removal.

WARNING To avoid injury, make sure long sections of pipe are supported at the end farthest away from the vise prior to removal.

14.Clean any oil spills or splatter on the ground sur- rounding the vise and oiler.

Ridge Tool Company | 9 |