GAS PRESSURE SETTING

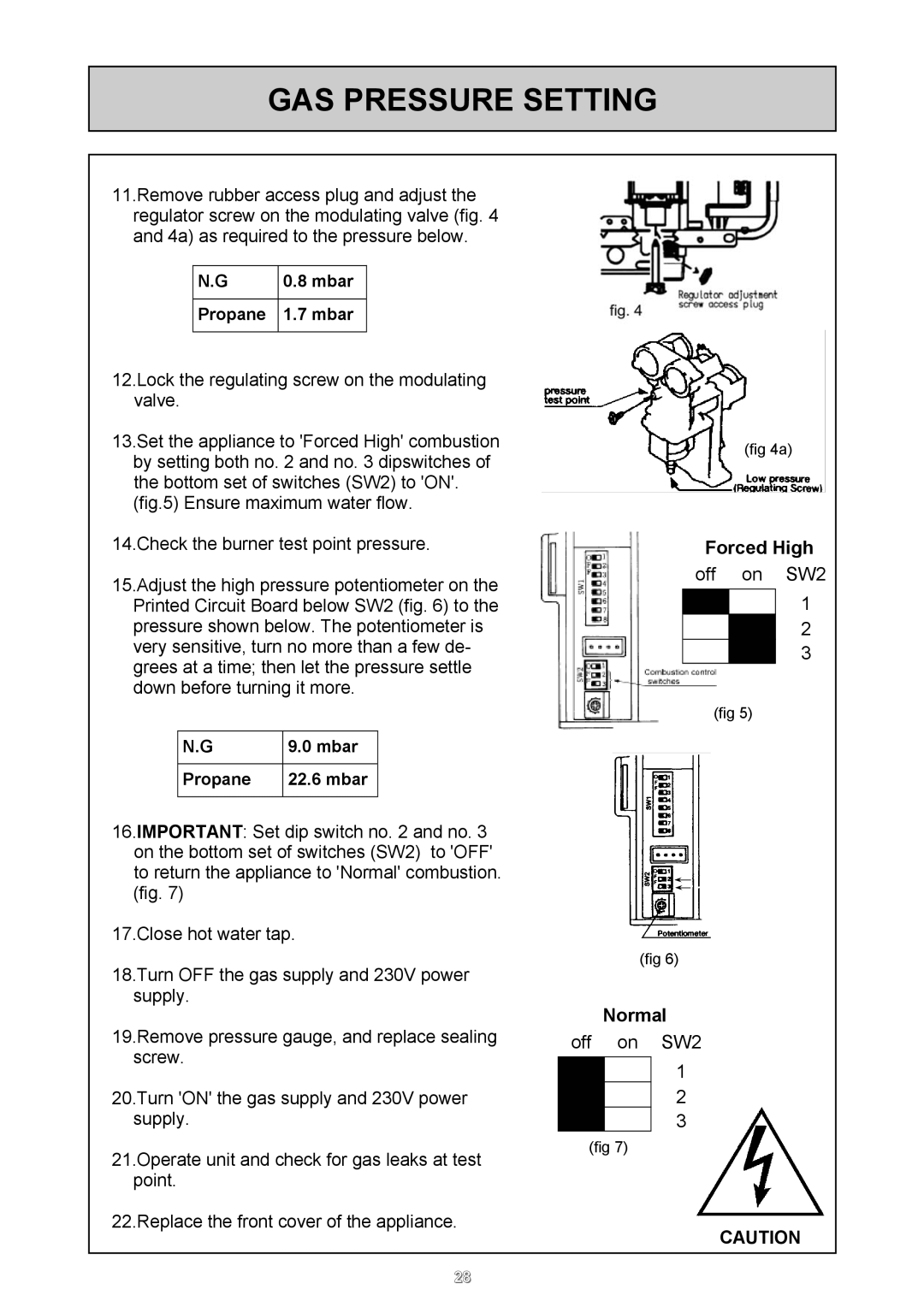

11.Remove rubber access plug and adjust the regulator screw on the modulating valve (fig. 4 and 4a) as required to the pressure below.

N.G | 0.8 mbar |

|

|

Propane 1.7 mbar

12.Lock the regulating screw on the modulating valve.

13.Set the appliance to 'Forced High' combustion by setting both no. 2 and no. 3 dipswitches of the bottom set of switches (SW2) to 'ON'.

(fig.5) Ensure maximum water flow.

14.Check the burner test point pressure.

15.Adjust the high pressure potentiometer on the Printed Circuit Board below SW2 (fig. 6) to the pressure shown below. The potentiometer is very sensitive, turn no more than a few de- grees at a time; then let the pressure settle down before turning it more.

N.G | 9.0 mbar |

|

|

Propane | 22.6 mbar |

|

|

16.IMPORTANT: Set dip switch no. 2 and no. 3 on the bottom set of switches (SW2) to 'OFF' to return the appliance to 'Normal' combustion. (fig. 7)

17.Close hot water tap.

18.Turn OFF the gas supply and 230V power supply.

19.Remove pressure gauge, and replace sealing screw.

20.Turn 'ON' the gas supply and 230V power supply.

21.Operate unit and check for gas leaks at test point.

22.Replace the front cover of the appliance.

28

(fig 4a)

Forced High

off on SW2 ![]() 1

1

2

3

(fig 5)

(fig 6)

Normal

off on SW2 1 2

3

(fig 7)

CAUTION