GENERAL INFORMATION

OPERATION

![]() WARNING:

WARNING:

![]() WARNING:

WARNING:

Before performing any adjustment, make sure the drill press is unplugged from the power supply and the switch is in the OFF position. Failure to heed this warning could result in serious personal injury.

![]() WARNING:

WARNING:

Your drill press has a precision built electric motor. It should only be connected to a power supply that is 120 volts, 60 Hz, AC only (normal household current). Do not operate this tool on direct current (DC). A substantial voltage drop will cause a loss of power and the motor will overheat. If your tool does not operate when plugged into an outlet, double check the power supply.

ON/OFF SWITCH KEY

Your drill press is equipped with an on/off switch key. When removed, the switch key prevents the drill press from being turned on. The key must be in place to turn the drill press on. If the key is removed during operation, the drill press can be turned off but may not be turned on again until the key is replaced.

ON/OFF SWITCH KEY

Always remember to remove the chuck key from the table surface before turning on the drill press. Failure to heed this warning could result in serious personal injury.

![]() WARNING:

WARNING:

Do not attempt to operate this tool until you have read thoroughly and understand completely all instructions, safety rules, etc. contained in this manual. Failure to comply can result in accidents involving fire, electric shock, or serious personal injury. Save this operator’s manual and review it frequently for continuing safe operation and instructing others who may operate this tool.

![]() WARNING:

WARNING:

Before attempting to use your drill press familiarize yourself with all operating features and safety requirements.

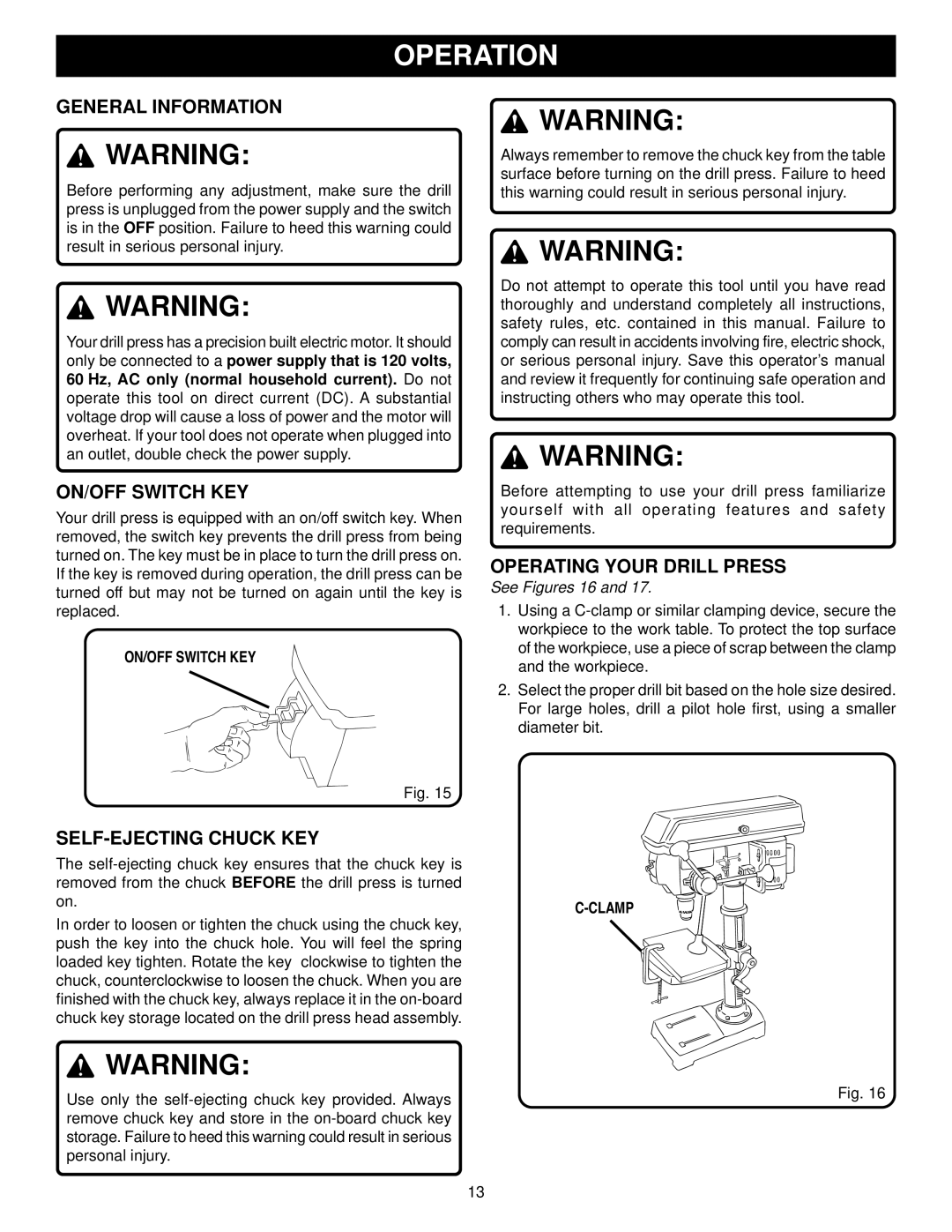

OPERATING YOUR DRILL PRESS

See Figures 16 and 17.

1.Using a

2.Select the proper drill bit based on the hole size desired. For large holes, drill a pilot hole first, using a smaller diameter bit.

Fig. 15

|

| |

The |

| |

removed from the chuck BEFORE the drill press is turned |

| |

on. | ||

In order to loosen or tighten the chuck using the chuck key, | ||

| ||

push the key into the chuck hole. You will feel the spring |

| |

loaded key tighten. Rotate the key clockwise to tighten the |

| |

chuck, counterclockwise to loosen the chuck. When you are |

| |

finished with the chuck key, always replace it in the |

| |

chuck key storage located on the drill press head assembly. |

|

![]() WARNING:

WARNING:

Use only the | Fig. 16 |

| |

remove chuck key and store in the |

|

storage. Failure to heed this warning could result in serious |

|

personal injury. |

|

13