OPERATION

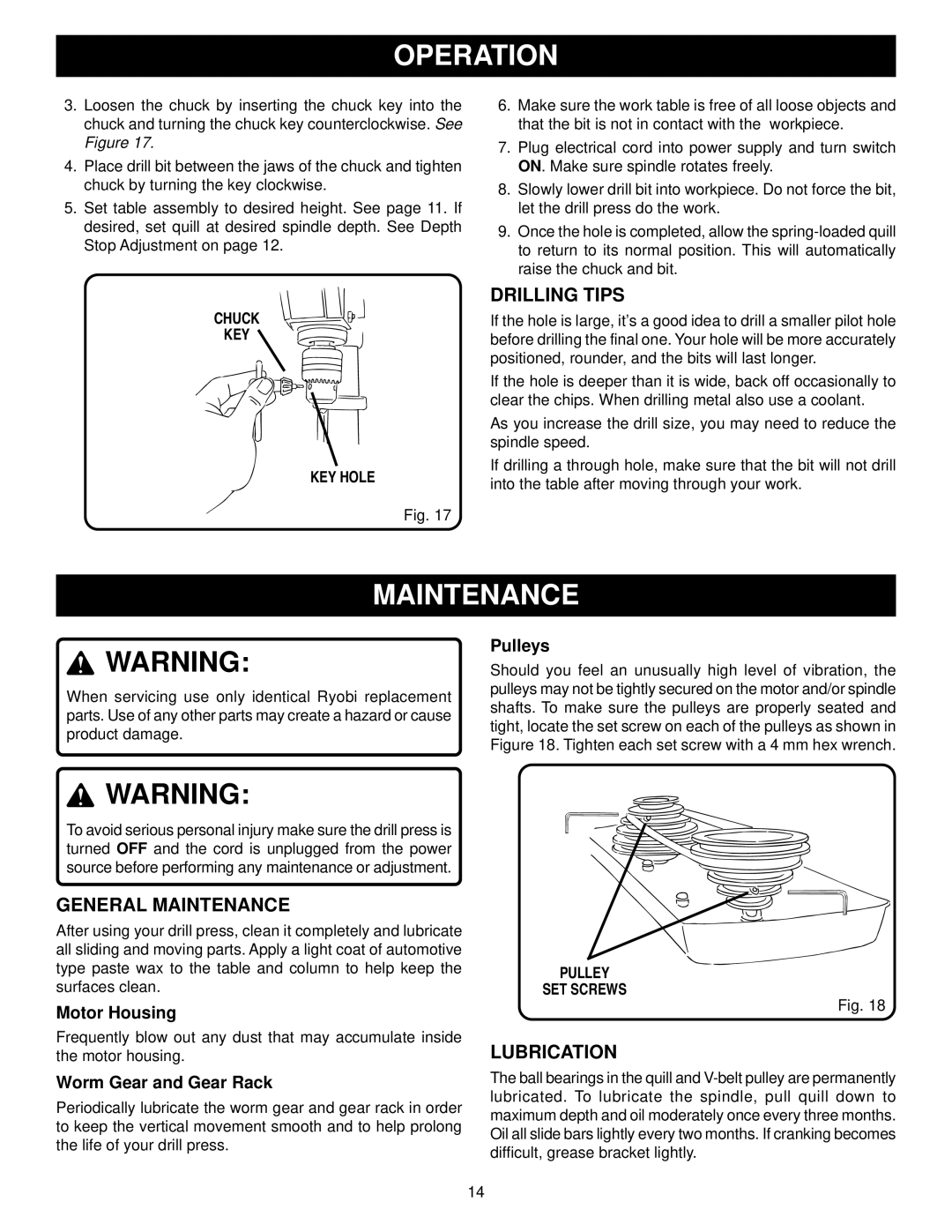

3.Loosen the chuck by inserting the chuck key into the chuck and turning the chuck key counterclockwise. See Figure 17.

4.Place drill bit between the jaws of the chuck and tighten chuck by turning the key clockwise.

5.Set table assembly to desired height. See page 11. If desired, set quill at desired spindle depth. See Depth Stop Adjustment on page 12.

CHUCK

KEY

KEY HOLE

Fig. 17

6.Make sure the work table is free of all loose objects and that the bit is not in contact with the workpiece.

7.Plug electrical cord into power supply and turn switch ON. Make sure spindle rotates freely.

8.Slowly lower drill bit into workpiece. Do not force the bit, let the drill press do the work.

9.Once the hole is completed, allow the

DRILLING TIPS

If the hole is large, it’s a good idea to drill a smaller pilot hole before drilling the final one. Your hole will be more accurately positioned, rounder, and the bits will last longer.

If the hole is deeper than it is wide, back off occasionally to clear the chips. When drilling metal also use a coolant.

As you increase the drill size, you may need to reduce the spindle speed.

If drilling a through hole, make sure that the bit will not drill into the table after moving through your work.

MAINTENANCE

![]() WARNING:

WARNING:

When servicing use only identical Ryobi replacement parts. Use of any other parts may create a hazard or cause product damage.

Pulleys

Should you feel an unusually high level of vibration, the pulleys may not be tightly secured on the motor and/or spindle shafts. To make sure the pulleys are properly seated and tight, locate the set screw on each of the pulleys as shown in Figure 18. Tighten each set screw with a 4 mm hex wrench.

![]() WARNING:

WARNING:

To avoid serious personal injury make sure the drill press is turned OFF and the cord is unplugged from the power source before performing any maintenance or adjustment.

GENERAL MAINTENANCE

After using your drill press, clean it completely and lubricate all sliding and moving parts. Apply a light coat of automotive type paste wax to the table and column to help keep the surfaces clean.

Motor Housing

Frequently blow out any dust that may accumulate inside the motor housing.

Worm Gear and Gear Rack

Periodically lubricate the worm gear and gear rack in order to keep the vertical movement smooth and to help prolong the life of your drill press.

PULLEY

SET SCREWS

Fig. 18

LUBRICATION

The ball bearings in the quill and

14