ASSEMBLY

TOOLS NEEDED FOR ASSEMBLY

#1 and #2 Philips Screwdriver Adjustable Wrench Hammer or rubber mallet

1.Place the base on a flat surface and assemble the column to the base using the four M8 hex bolts.

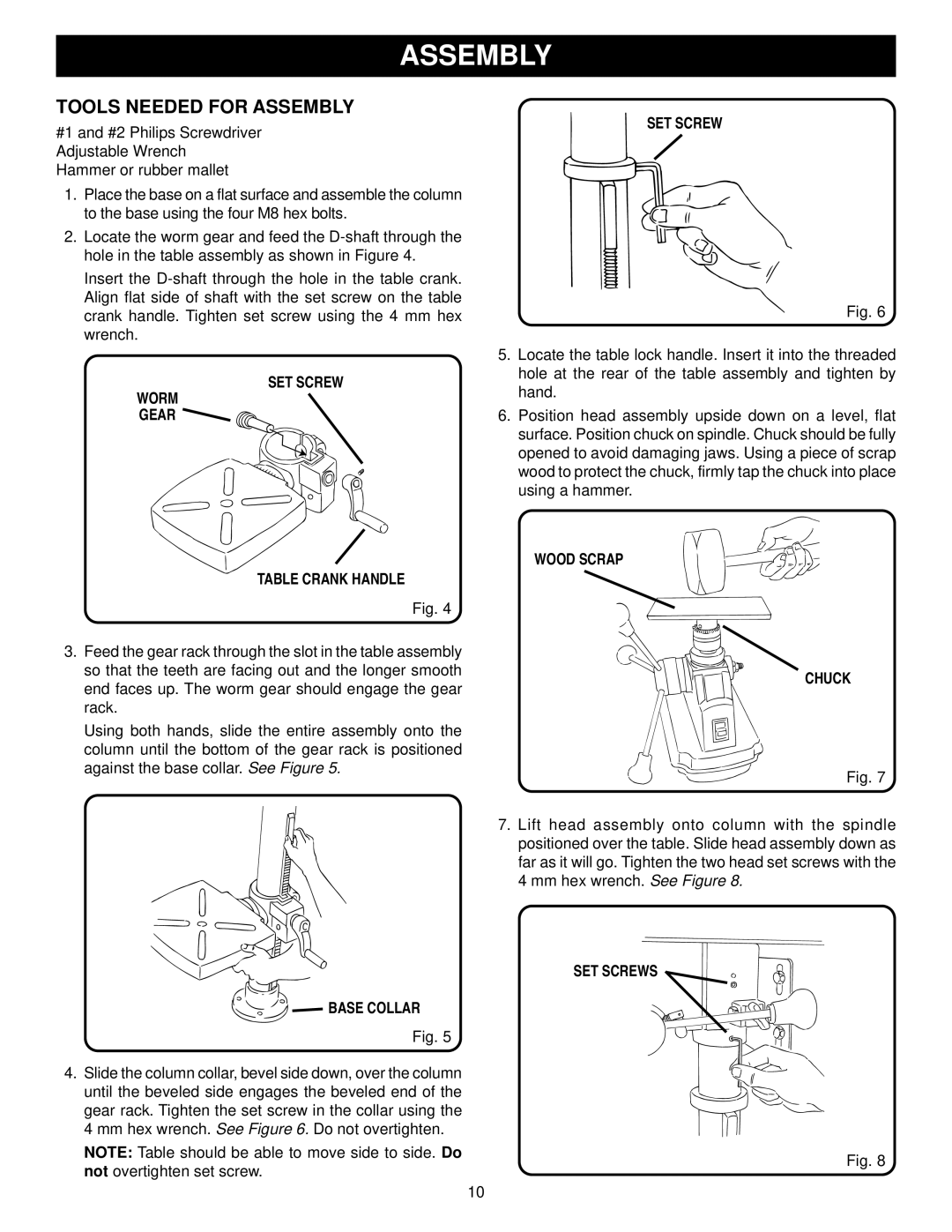

2.Locate the worm gear and feed the

Insert the

SET SCREW

WORM

GEAR

TABLE CRANK HANDLE

Fig. 4

3.Feed the gear rack through the slot in the table assembly so that the teeth are facing out and the longer smooth end faces up. The worm gear should engage the gear rack.

Using both hands, slide the entire assembly onto the column until the bottom of the gear rack is positioned against the base collar. See Figure 5.

SET SCREW

Fig. 6

5.Locate the table lock handle. Insert it into the threaded hole at the rear of the table assembly and tighten by hand.

6.Position head assembly upside down on a level, flat surface. Position chuck on spindle. Chuck should be fully opened to avoid damaging jaws. Using a piece of scrap wood to protect the chuck, firmly tap the chuck into place using a hammer.

WOOD SCRAP

CHUCK

Fig. 7

7.Lift head assembly onto column with the spindle positioned over the table. Slide head assembly down as far as it will go. Tighten the two head set screws with the 4 mm hex wrench. See Figure 8.

BASE COLLAR

BASE COLLAR

Fig. 5

4.Slide the column collar, bevel side down, over the column until the beveled side engages the beveled end of the gear rack. Tighten the set screw in the collar using the 4 mm hex wrench. See Figure 6. Do not overtighten.

NOTE: Table should be able to move side to side. Do not overtighten set screw.

SET SCREWS

Fig. 8

10