Table Saw specifications

The Ryobi Table Saw is a powerful and versatile tool designed for both hobbyists and professional woodworkers. Known for its durability and efficiency, this table saw is an essential addition to any workshop. One of its standout features is the high-performance motor, which typically operates at 15 amps, delivering ample power to handle a variety of cutting tasks with ease. This ensures that it can cut through hardwood, softwood, and even plywood without bogging down.A notable characteristic of the Ryobi Table Saw is its precision. Equipped with a robust aluminum table, the saw offers a flat, sturdy surface that promotes accurate cuts. The table is typically expansive, allowing users to work on larger materials without difficulty. With the inclusion of rack and pinion fence system, users can make quick adjustments to the blade position, ensuring that each cut is clean and precise. The fence system is user-friendly, allowing for smooth adjustments with minimal effort.

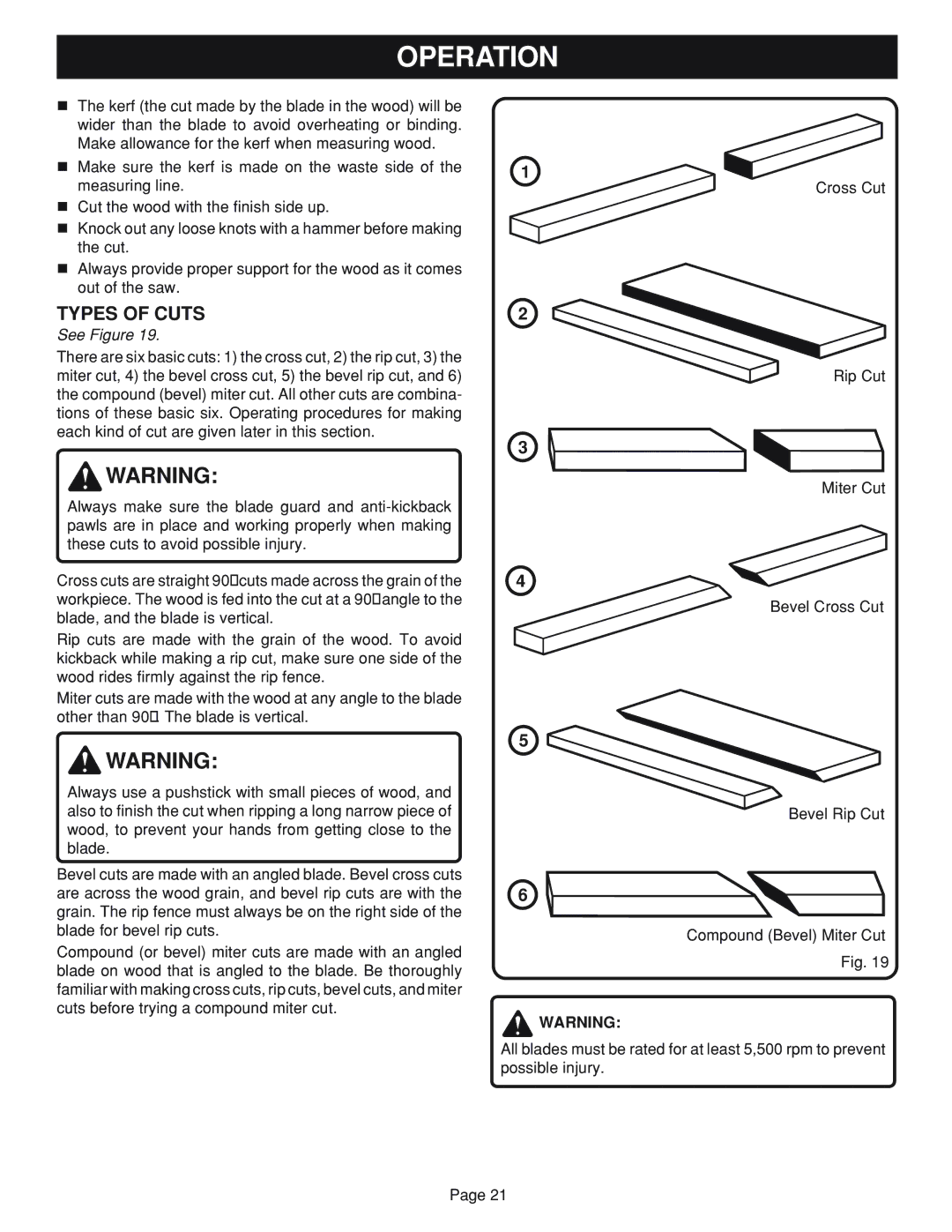

Safety is a top priority in Ryobi's design, and this is reflected in various features like the blade guard and anti-kickback pawls. The blade guard provides visibility of the cut line while protecting the user from potential injury. Additionally, the saw often includes a push stick, which helps maintain a safe distance from the blade during operation.

Another key technology found in the Ryobi Table Saw is its portability. Many models are designed to be lightweight and feature wheels, making it easy to move the saw from one location to another. This is particularly advantageous for contractors or those who have limited workshop space.

Dust collection is also an important aspect of woodworking, and the Ryobi Table Saw typically includes a built-in dust port. This enables users to connect a shop vac or dust collector, minimizing the mess and ensuring a cleaner work environment.

In summary, the Ryobi Table Saw integrates powerful performance with user-friendly features. Its precision cutting capabilities, safety mechanisms, and portability make it an excellent tool for anyone looking to tackle woodworking projects. Whether you're a seasoned professional or a DIY enthusiast, the Ryobi Table Saw can elevate your craftsmanship and improve your woodworking efficiency.