Samsung Electronics

Functional parts and safety devices

Indoor unit PCB

Noise level

Electronic expansion valve kit

IOverview

What is DVM?

DVM system series

Comparison of DVM with conventional air conditioners

Features of DVM

Customized air conditioner

DVM air conditioner

Variable compressor

Principle of the digital compressor

Refrigerant flow rates control

PWM Pulse Width Modulation valve

Convenient centralized control

Easy installation

Long & single piping system

Minimizing operation costs

Space Saving

Conventional System DVM System

Zone Test

DVM vs VAV

Excellent energy efficiency

Zone control conditions

DVM test condition

VAV test condition

Zone control Sample #1 Sample #2 Sample #3 Sample #4

Indoor unit and outdoor unit Conventional model Model

DVM line-up

Numbering system of model

Indoor unit

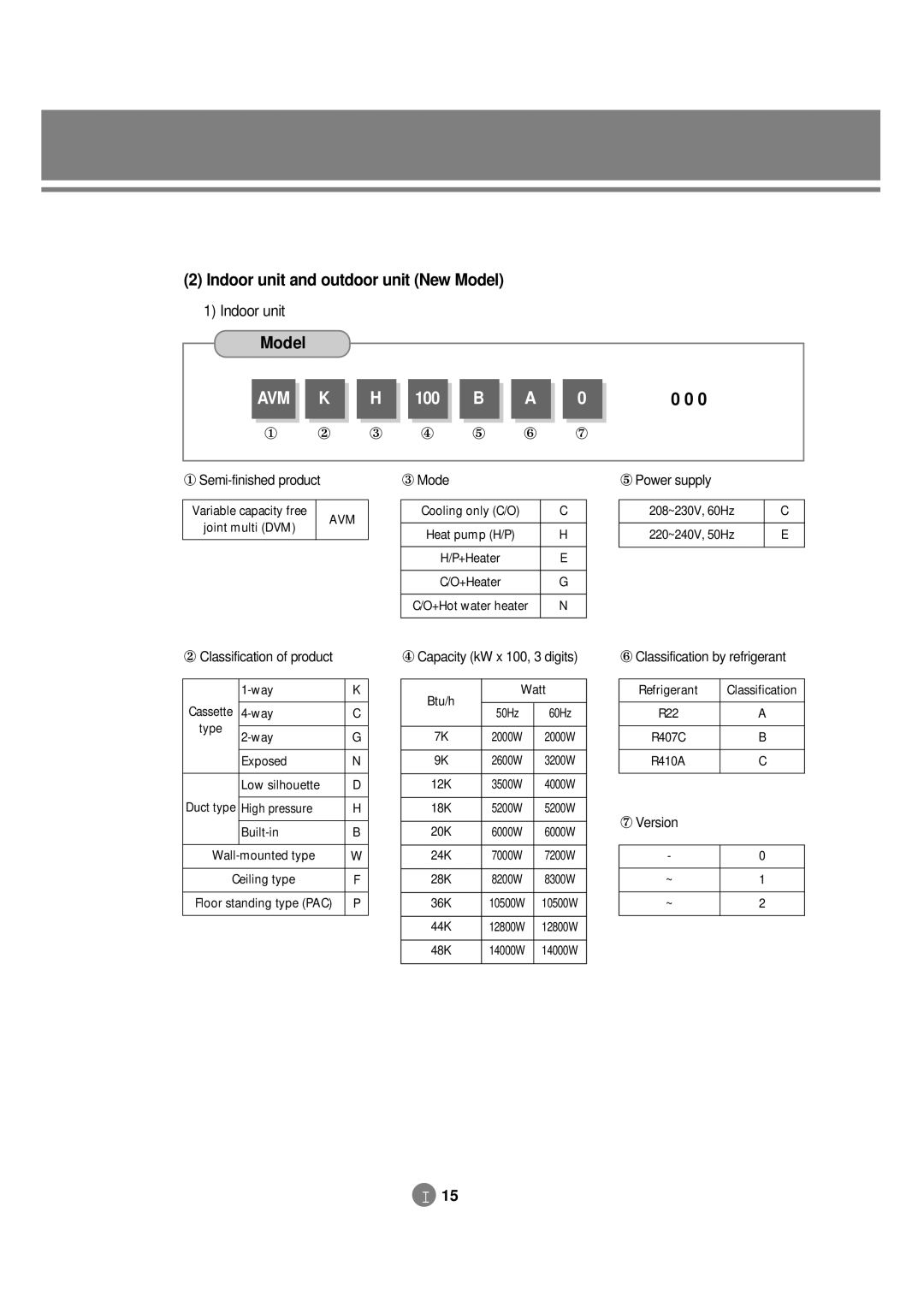

Indoor unit and outdoor unit New Model

Model

⑥ Combination of indoor unit

④ Power supply

② Mode

③ Capacity HP x 10, 3 digits

Options

Parts Model Standard for model name Example

MCM- ① ② ③ ④

MSC- ① ② ③ ④ ⑤

Outdoor unit

Design Power supply Model CapacityHP Refrigerant Main

Combination

Cooling only

Indoor units

Design Max. connectible

Super Remark Main

Cooler

Heat pump

~20.8 ~18.8 11.0~29.0 14.0~36.4 14.0~28.0

Indoor unit

Design Power 0kW 6kW 2kW 5kW

System line-up

Design Power 0kW 2kW 3kW

IIControl System

Remote controller

Wireless remote controller

Duct type

Timer Cancel button

On/Off & Timer set/cancel button Heat pump Operating mode

Selection button

Wired remote controller

On/Off timer button

Operating mode Selection button Heat pump

Cooling only Operating mode

Temperature

Operating mode Selection button

Centralized controller

Operating mode Temperature adjustment On/Off button Buttons

Test button Filter reset button Mode selection button

Function controller

Cooling only

Receiver & display unit Duct type

Concealed type

Heat pump

Standard type

Transmitter

Installation

Installation

Accessories

Wired Remote Controller Cable-Tie2

Original Position

Setting up option switches

Switch No

Example of installing wired remote controller

Individual control

Wiring diagram

Transmitter installation

Assigning address

Button No

Case of Installing wired remote controller together

SW03 switch in indoor unit Transmitter

Switch Meaning

Level of centralized controller

Reassemble the function controller

Centralized Controller Adaptor

Function Controller Outdoor unit Indoor unit

Receiver & display unit Concealed type

Receiver & display unit Standard type

Transmitter

Outdoor unit Transmitter Centralized Controller Indoor unit

Assigning address

Indoor unit

Outdoor unit

Operation method Applicable button

Indoor unit PCB option code

PCB option code input method example 021E31142285

Step

Indoor unit PCB option code

2 ~7 steps, press the mode button to make the first digit

Indoor unit PCB option code

Step Error

Option code

Type Model

AVMWC072CA0

AVMWC026EA0 AVMWC032CA0 AVMWC035EA0 AVMWC040CA0

AVMWC070EA0

AVMWH026EA0 AVMWH032CA0 AVMWH035EA0 AVMWH040CA0

Net

Integrating power distribution system

Building management system

IIIIndoor unit

Efficient cooling & stylish design

Features

Way cassette type

Features of the 1-way cassette type

Bio heat exchanger & air filter

Powerful functions

Higher & broader cooling

Features of 4-way cassette type

Fan speed adjustment

High external static pressure

Economic installation

Duct type

External static pressure Fan speed

Low silhouette High pressure Model

Features of Duct type

Built-in

BIO-components

Features of wall-mounted type

Wall-mounted type

Cross fan Body Bio pure air filter

Look at how well these filters perform

Features of floor standing type

Floor standing type

Button

On/Off Fan speed

Turbo

Sensor Button

Bio tech for fresh air and advanced function

Convenient installation

Ceiling type

Features of ceiling type

Long life filter with antibacterial treatment

Specification

50Hz

60Hz

Btu/h 18000 24000 36000 10.5 Heating 19000 26000 39000 11.4

Btu/h 18000 24000 36000 10.5

Duct type Low silhouette

AVMDC052EA0 AVMDC070EA0 AVMDH052EA0 AVMDH070EA0

AVMDC052CA0 AVMDC072CA0 AVMDH052CA0 AVMDH072CA0

Duct type Built-in

AVMBH020EA0 AVMBH026EA0 AVMBH035EA0 AVMBH052EA0 AVMBH070EA0

AVMBC032CA0

AVMBH020CA0 AVMBH032CA0 AVMBH040CA0 AVMBH052CA0 AVMBH072CA0

Duct type High pressure

AVMHC105EA0 AVMHC128EA0 AVMHH105EA0 AVMHH128EA0

AVMHC105CA0 AVMHC128CA0 AVMHH105CA0 AVMHH128CA0

220 ~ 240

AVMWH020EA0 AVMWH026EA0 AVMWH035EA0 AVMWH052EA0 AVMWH070EA0

AVMWC020CA0 AVMWC032CA0 AVMWC040CA0 AVMWC052CA0 AVMWC072CA0

4mmAq Output

Btu/h 20000 24000 28000 Heating 22000 26000 30000

AVMPC060CA0

AVMFC052EA0 AVMFC070EA0 AVMFH052EA0 AVMFH070EA0

AVMFC052CA0 AVMFC072CA0 AVMFH052CA0 AVMFH072CA0

EIS

Functional parts and safety devices

Code Name

103AT 25C=10k Ω

Code

Name

AVMWC052EA0

AVMPC083CA0 AVMPH083CA0

Capacity table

Cooling

TC Total capacity Outdoor Indoor temperature ºC, WB

12.80

Outdoor temperature Indoor temperature ºC, DB

Heating

11.4

13.8

20.0 22.0 24.0 Unit Size Temperature ºC, WB 020 14.6 032 040

20.0

10.5

Unit Size 020 032 040

Unit Size 052 072 105

13.8

Dimension

Unit mm

2kW ~ 7.2kW

10.5kW

Duct type Low silhouette

0kW ~ 4.0kW

2kW ~ 7.2kW

Duct type High pressure

Wall-Mounted type

2kW ~ 7.2kW

600mm

Ceiling type

Wireless remote controller / Receiver

MR-AC01 MR-AH01

Fan indicator Filter sign indicator

Remote control sensor Timer indicator On/off indicator

Remote control sensor Timer indicator

MGKC118IE0 MGKC118IM0 MGKC118IA0 MGKC118IC0

On/off button Fan indicator Removing frost indicator

Timer indicator On/off button

Timer indicator Remote control sensor

On/off indicator Filter sign indicator

On/off button Fan indicator

Avmwc

Operating mode Temperature Selection button

Avmpc

Avmfc Avmfh

For duct type Avmd / Avmb / Avmh

MR-AC00 MR-AH00

MRK-B00concealed type MRW-10Awire kit MRK-A00standard type

MWR-AC01 Wiring hole MWR-AH01

MWR-AC00 Wiring hole MWR-AH00

Option controller

Centralized controller Function controller

Main parts status

Refrigerant system diagramCooling only & heat pump

Refrigerant system diagram

Electric circuit diagram

Cooling only Avmkc

Heat pump Avmkh

Cooling only Avmcc

Heat pump Avmch

Cooling only Avmdc / Avmbc / Avmhc

Heat pump Avmdh / Avmbh / Avmhh

Cooling only Avmwc

Heat pump Avmwh

Cooling only Avmpc

Heat pump Avmph

Cooling only Avmfc

Heat pump Avmfh

Duct typeBuilt-in

Noise level

Overall

026/032

Octave band level

Way cassette type

035/040

052

070/072

105

Duct type Low silhouette

Duct type Built-in

035/040

070/072

Duct type High pressure

128

Wall-mounted type

035/040

070/072

Floor standing type

060

082/083

Ceiling type

AVMKH035

Velocity of air flow & temperature distribution

Heating temperature distribution

Velocity of air flow

29 C

AVMCH070

35 C

AVMCH105

32 C 29 C

AVMWH035

26 C

AVMWH070

29 C 32 C 26 C

AVMFH070

Fan Speed CMM

Fan specifications

Duct type Low silhoutte

Fan speed m3/min

070/072 026/032

Fan speed m3/min External static pressure mmAq

Duct type High pressure

Air flow m3/min

Model Language

Panel

Design Status

MGKC118IE0

MGCC095IE0

MGCH095IE0

MEV-14 MEV-18

Electronic expansion valve kit

Design Status depending on the combination

Options

Mandatory items

Optional items

MR-AC01

116

IVOutdoor unit

Outdoor unit selection

Unit selection with cooling load

Indoor unit selection

Real function data

Indoor unit selection

Example for unit selection with cooling load

Given condition

Outdoor unit selection

RVMC060GAM0 RVMC060GDM0 RVMC100GAM0

186 158 310

Charge

ISO

Saso

Output Fan output Type

ZRD72KCE-TFD

CMS

CCH

HPS

SUC.S

RVMH050CBM0 RVMH060GBM0

RVMH100GAM0 RVMH100FAM0

ZRDT14MC-TFD

Coil Siginomiya

Super cooler

MUF7201F1 SUB

Cooling

16.0

TC Total capacity, PI Power input

Outdoor Indoor temperature ºC, WB

28.0

TC Total capacity, PI Power input

Combination Indoor temperature ºC, DB

Indoor temperature ºC, DB Outdoor temperature

100

16.2

TC Total capacity, PI Power input

16.0

TC Total capacity, PI Power input

20.8

TC Total capacity, PI Power input

28.0

TC Total capacity, PI Power input

100 10.6 10.4

060

Indoor temperature ºC, DB Outdoor temperature

Upward 2-FAN

Onward

Upward 1-FAN

UpwardSuper cooler

Refrigerant system diagram

Cooling only

080/100

PWM

Main parts status

Heat pump

050/060

Hgbv

Main parts status

Check valve C/V

13 4-way valve 4-W/V

Electronic expansion valve EEV

16 SUC.S Suction sensor

Cooling only

050/060/072

080/100

Heat pump

080/100

Change of cooling capacity Change of heating capacity

Consideration for outdoor unit selection

Change of capacity depending on refrigerant piping length

Condition of operating restriction

Cooling Heating

035

080/100

MDF-46A

Design Capacity Optional Items

MDF-45A

VInstallation

Product

Preparation for installation

Moving the outdoor unit by wire rope

General

Deciding on where to install the air conditioner

Space requirements for the air conditioner

Duct type Low silhouette

Ore

Floor standing type Ceiling type

If there is no obstacle around the outdoor unit

Unit mm

Accessories

Installation Drain sub Instructions Manual

Floor standing type Ceiling type

Installation

Indoor unit Example 4-way cassette type

Fix the outdoor unit with anchor bolts

STS 2S-2x10

Reinstall the front grille

Secure the panel to the indoor unit using the bolts4EA

020/026/035

020/026/035

Connecting the indoor unit refrigerant pipe

There are two refrigerant pipes of differing diameters

Cutting/Flaring the Pipes

Drain hose installation Example4-way cassette type

Testing the drainage

Drain pump installation-optional

Wiring

Overall system configuration example

Wiring diagram

Cable specification for outdoor unit

Connection cord specification

Indoor unit

Connection cord wiring diagram

Power wiring and communication wiring configuration

F1 F1 F2 F2

Communication cable connection

Correct connection

Outdoor unit Indoor unit

Typical wiring error

Star wiring connection to some of the indoor units

Star wiring connection to every indoor units

Outdoor unit Indoor unit Wired remote Controller

Reverse wiring between indoor and outdoor units

Wired remote Controller

Disconnection between indoor and outdoor units

Reverse wiring between indoor units

Disconnection between indoor units

Piping selection

Refrigerant piping system diagram

Piping and refnet joint selection

Refnet joint model

Refnet joint selection

Other refnet joint selection method

Diameter mm

Charge/recovery of refrigerant

Indoor unit Scale

Pipe diameter mm

Additional refrigerant amount calculation method

Example of additional refrigerant amount calculation

Recovery of refrigerant

Check the outdoor unit

Testing operation

Check the indoor unit

Check the high and low pressure through the manifold gauge

Check through the PC connected to the outdoor unit

Introduction

Outdoor unit Direction System No

Outdoor unit Indoor unit Opening between rooms Partition

Calculate the smallest room volumem3

Concentration

Room

Indoor unit Action

Lowing courses of action

Action

DB98-03759A1