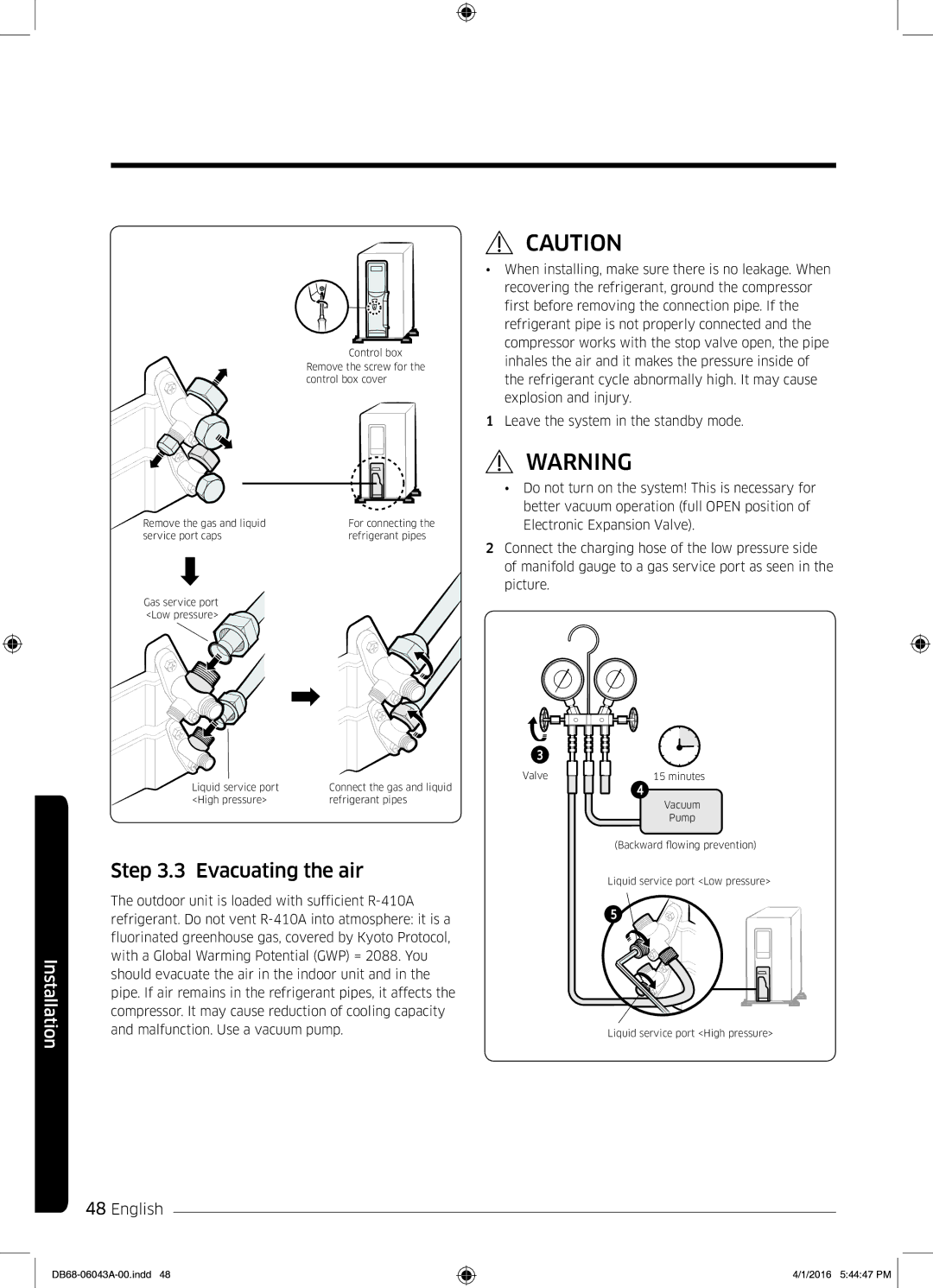

Control box

Remove the screw for the control box cover

Remove the gas and liquid | For connecting the |

service port caps | refrigerant pipes |

Gas service port <Low pressure>

![]() CAUTION

CAUTION

•When installing, make sure there is no leakage. When recovering the refrigerant, ground the compressor first before removing the connection pipe. If the refrigerant pipe is not properly connected and the compressor works with the stop valve open, the pipe inhales the air and it makes the pressure inside of the refrigerant cycle abnormally high. It may cause explosion and injury.

1Leave the system in the standby mode.

![]() WARNING

WARNING

•Do not turn on the system! This is necessary for better vacuum operation (full OPEN position of Electronic Expansion Valve).

2Connect the charging hose of the low pressure side of manifold gauge to a gas service port as seen in the picture.

Liquid service port | Connect the gas and liquid |

<High pressure> | refrigerant pipes |

Step 3.3 Evacuating the air

| The outdoor unit is loaded with sufficient | |

| refrigerant. Do not vent | |

| fluorinated greenhouse gas, covered by Kyoto Protocol, | |

Installation | with a Global Warming Potential (GWP) = 2088. You | |

should evacuate the air in the indoor unit and in the | ||

| ||

| pipe. If air remains in the refrigerant pipes, it affects the | |

| compressor. It may cause reduction of cooling capacity | |

| and malfunction. Use a vacuum pump. |

48English

3

Valve

15 minutes

4

Vacuum

Pump (Backward flowing prevention)

Liquid service port <Low pressure>

5

Liquid service port <High pressure>

4/1/2016 5:44:47 PM