NO | ITEMS |

|

| TEST CONDITION |

|

|

| PERFORMANCE |

|

| ||||||

|

| THE CAPACITOR SHALL BE STORED AT A | CHANGE IN CAPACITANCE : |

| ||||||||||||

|

| TEMPERATURE OF 40 | 2 | AND RELATIVE | WITHIN : | 10% OF THE |

| |||||||||

|

|

|

|

|

| ± ℃ |

|

|

|

| 8 HOURS. |

| ± |

|

| |

|

| HUMIDITY OF 90% TO 95% FOR 500 | INITIAL VALUE |

| ||||||||||||

| MOISTURE |

|

|

|

|

|

|

|

| ± |

|

|

|

| ||

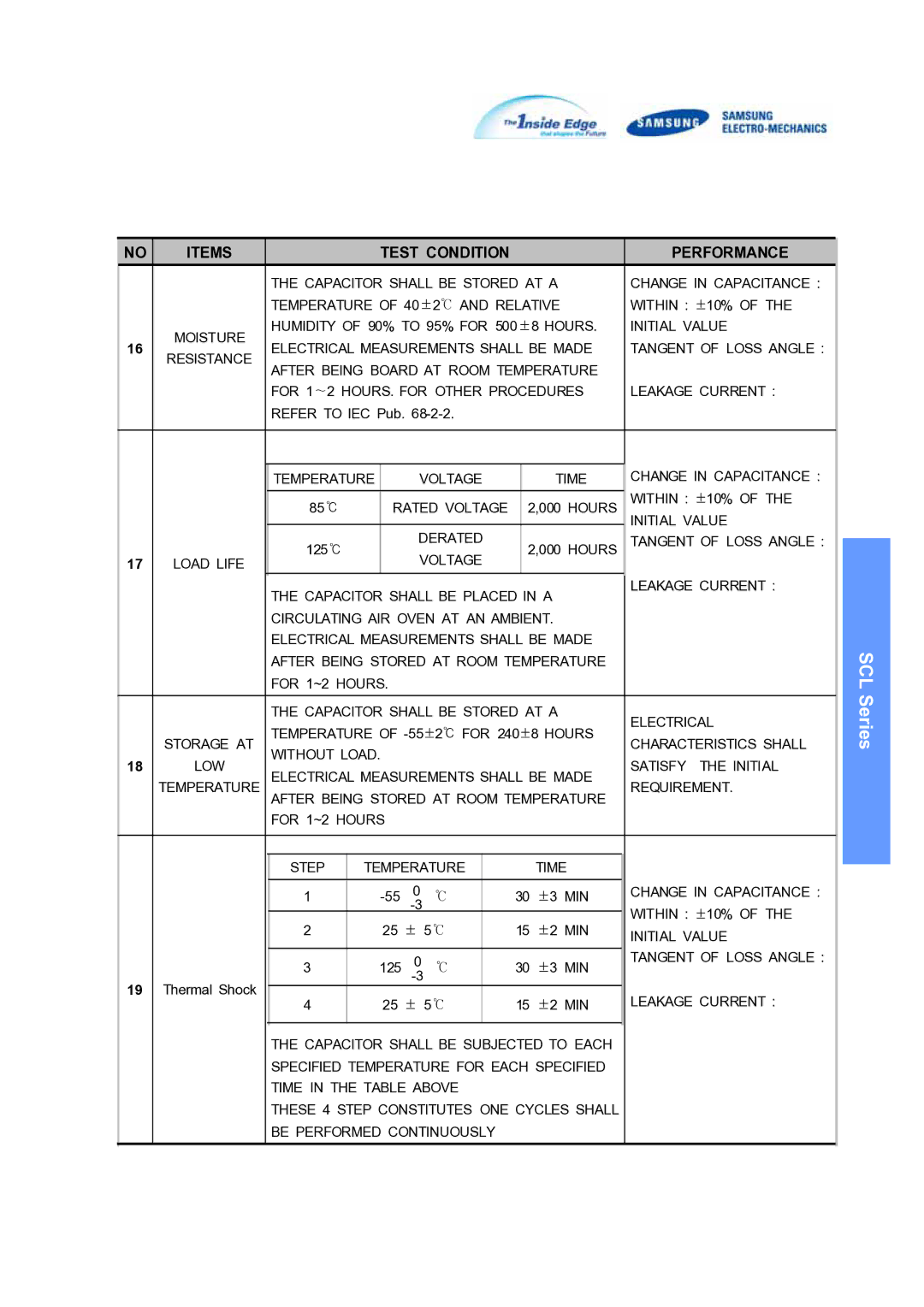

16 | ELECTRICAL MEASUREMENTS SHALL BE MADE | TANGENT OF LOSS ANGLE : |

| |||||||||||||

RESISTANCE |

| |||||||||||||||

| AFTER BEING BOARD AT ROOM TEMPERATURE |

|

|

|

| |||||||||||

|

| LEAKAGE CURRENT : |

| |||||||||||||

|

| FOR 1 2 HOURS. FOR OTHER PROCEDURES |

| |||||||||||||

|

| ∼ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| REFER TO IEC Pub. |

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| CHANGE IN CAPACITANCE : |

| ||||||

|

| TEMPERATURE |

|

| VOLTAGE |

|

| TIME |

| |||||||

|

| 85℃ |

| RATED VOLTAGE |

| 2,000 HOURS | WITHIN : | 10% OF THE |

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ± |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| INITIAL VALUE |

| ||

|

|

|

|

|

| DERATED |

|

|

|

| ||||||

|

| 125℃ |

|

|

|

| 2,000 HOURS | TANGENT OF LOSS ANGLE : |

| |||||||

|

|

|

|

|

|

| ||||||||||

17 | LOAD LIFE |

|

|

| VOLTAGE |

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

| ||||||

|

| THE CAPACITOR SHALL BE PLACED IN A | LEAKAGE CURRENT : |

| ||||||||||||

|

|

|

|

|

| |||||||||||

|

| CIRCULATING AIR OVEN AT AN AMBIENT. |

|

|

|

| ||||||||||

|

| ELECTRICAL MEASUREMENTS SHALL BE MADE |

|

|

| SCL | ||||||||||

|

| AFTER BEING STORED AT ROOM TEMPERATURE |

|

|

| |||||||||||

|

| FOR 1~2 HOURS. |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| Series | ||||||

|

| THE CAPACITOR SHALL BE STORED AT A | ELECTRICAL | |||||||||||||

|

|

|

|

|

| ± ℃ |

|

| ± | |||||||

| STORAGE AT | TEMPERATURE OF | 2 | FOR 240 | 8 HOURS | CHARACTERISTICS SHALL | ||||||||||

| WITHOUT LOAD. |

|

|

|

|

|

|

|

| |||||||

18 | LOW |

|

|

|

|

|

|

|

| SATISFY | THE INITIAL |

| ||||

ELECTRICAL MEASUREMENTS SHALL BE MADE |

| |||||||||||||||

| TEMPERATURE | REQUIREMENT. |

| |||||||||||||

|

| AFTER BEING STORED AT ROOM TEMPERATURE |

|

|

|

| ||||||||||

|

| FOR 1~2 HOURS |

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

| STEP | TEMPERATURE |

|

|

| TIME |

|

|

|

| |||||

|

|

|

|

|

|

|

| |||||||||

|

| 1 | 0 | ℃ |

|

| 30 ±3 MIN | CHANGE IN CAPACITANCE : |

| |||||||

|

|

|

|

| ± |

|

| |||||||||

|

| 2 | 25 |

| 5 |

|

|

| 15 | 2 MIN | WITHIN : | 10% OF THE |

| |||

|

|

|

|

| ± |

| ℃ |

|

|

|

| ± | INITIAL VALUE |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

| 3 | 125 | 0 | ℃ |

|

| 30 ±3 MIN | TANGENT OF LOSS ANGLE : |

| ||||||

19 | Thermal Shock |

|

|

|

|

|

| |||||||||

4 | 25 | ± | 5 | ℃ |

|

| 15 | ± | LEAKAGE CURRENT : |

| ||||||

|

|

|

|

| ||||||||||||

|

|

|

|

|

| 2 MIN |

|

|

|

| ||||||

THE CAPACITOR SHALL BE SUBJECTED TO EACH

SPECIFIED TEMPERATURE FOR EACH SPECIFIED

TIME IN THE TABLE ABOVE

THESE 4 STEP CONSTITUTES ONE CYCLES SHALL

BE PERFORMED CONTINUOUSLY