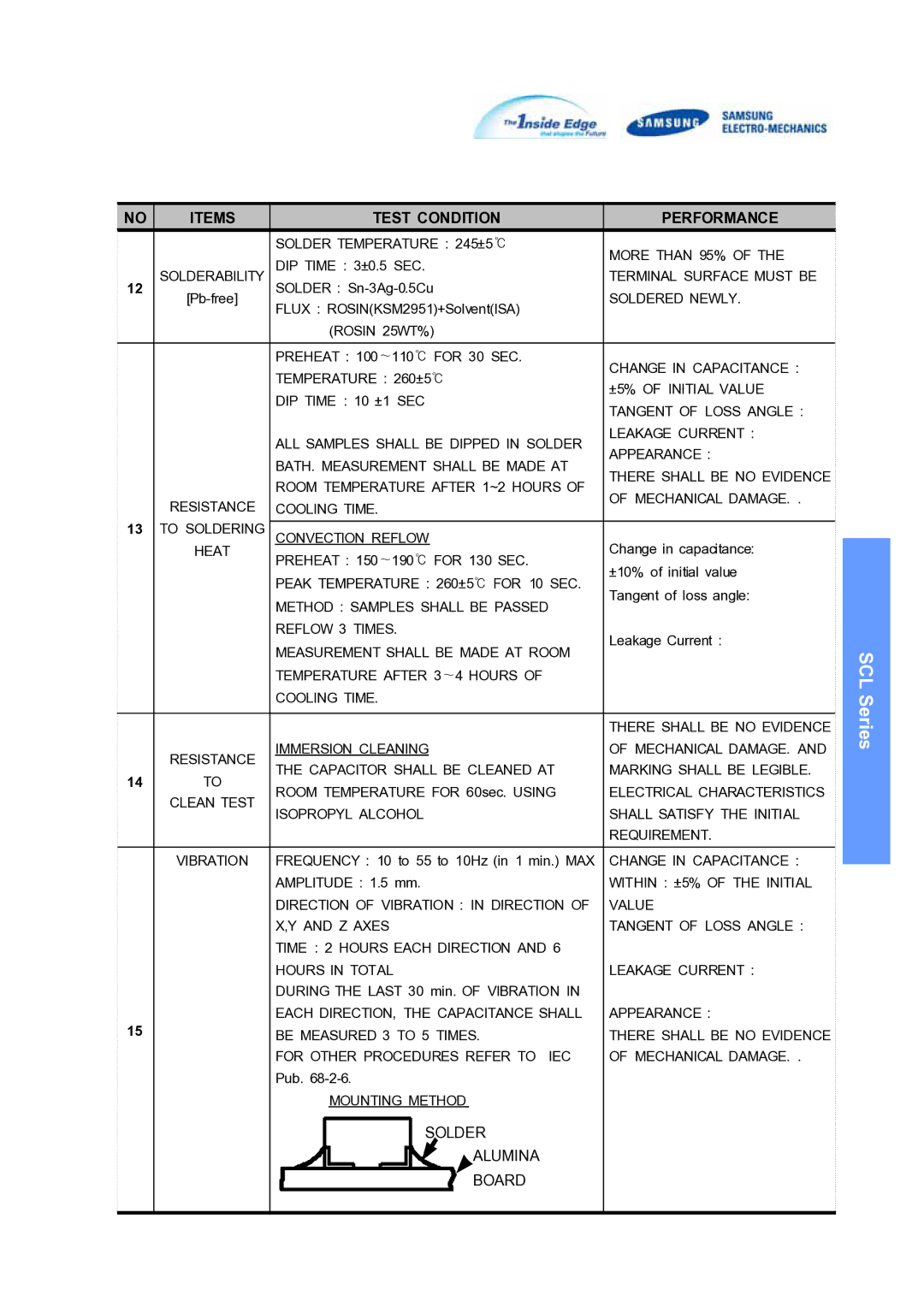

NO | ITEMS | TEST CONDITION | PERFORMANCE | |||

|

| SOLDER TEMPERATURE : 245±5℃ | MORE THAN 95% OF THE | |||

|

| DIP TIME : 3±0.5 SEC. |

| |||

12 | SOLDERABILITY |

| TERMINAL SURFACE MUST BE | |||

SOLDER : |

| SOLDERED NEWLY. | ||||

| FLUX : ROSIN(KSM2951)+Solvent(ISA) | |||||

|

|

| ||||

|

| (ROSIN 25WT%) |

| |||

|

|

|

|

|

| |

|

| PREHEAT : 100 110 |

| FOR 30 SEC. |

| |

|

| ∼ | ℃ |

| CHANGE IN CAPACITANCE : | |

|

|

| ℃ | |||

|

| TEMPERATURE : 260±5 |

| ±5% OF INITIAL VALUE | ||

|

| DIP TIME : 10 ±1 SEC |

| |||

|

|

| TANGENT OF LOSS ANGLE : | |||

|

|

|

|

| ||

|

| ALL SAMPLES SHALL BE DIPPED IN SOLDER | LEAKAGE CURRENT : | |||

|

| APPEARANCE : | ||||

|

| BATH. MEASUREMENT SHALL BE MADE AT | ||||

|

| THERE SHALL BE NO EVIDENCE | ||||

|

| ROOM TEMPERATURE AFTER 1~2 HOURS OF | ||||

|

| OF MECHANICAL DAMAGE. . | ||||

| RESISTANCE | COOLING TIME. |

|

| ||

|

|

|

| |||

13 | TO SOLDERING |

|

|

| ||

CONVECTION REFLOW |

| Change in capacitance: | ||||

| HEAT | ∼ | ℃ | FOR 130 SEC. | ||

|

| PREHEAT : 150 190 |

| ±10% of initial value | ||

|

|

|

| ℃ | ||

|

| PEAK TEMPERATURE : 260±5 FOR 10 SEC. | Tangent of loss angle: | |||

|

| METHOD : SAMPLES SHALL BE PASSED | ||||

|

|

| ||||

|

| REFLOW 3 TIMES. |

|

| Leakage Current : | |

|

| MEASUREMENT SHALL BE MADE AT ROOM | ||||

|

|

| ||||

|

| TEMPERATURE AFTER 3 4 HOURS OF |

| |||

|

|

|

| ∼ |

| |

|

| COOLING TIME. |

|

|

| |

|

|

|

|

|

| |

|

|

|

|

| THERE SHALL BE NO EVIDENCE | |

| RESISTANCE | IMMERSION CLEANING |

| OF MECHANICAL DAMAGE. AND | ||

| THE CAPACITOR SHALL BE CLEANED AT | MARKING SHALL BE LEGIBLE. | ||||

14 | TO | |||||

ROOM TEMPERATURE FOR 60sec. USING | ELECTRICAL CHARACTERISTICS | |||||

| CLEAN TEST | |||||

| ISOPROPYL ALCOHOL |

| SHALL SATISFY THE INITIAL | |||

|

|

| ||||

|

|

|

|

| REQUIREMENT. | |

|

|

|

| |||

| VIBRATION | FREQUENCY : 10 to 55 to 10Hz (in 1 min.) MAX | CHANGE IN CAPACITANCE : | |||

|

| AMPLITUDE : 1.5 mm. |

| WITHIN : ±5% OF THE INITIAL | ||

|

| DIRECTION OF VIBRATION : IN DIRECTION OF | VALUE | |||

|

| X,Y AND Z AXES |

|

| TANGENT OF LOSS ANGLE : | |

|

| TIME : 2 HOURS EACH DIRECTION AND 6 |

| |||

|

| HOURS IN TOTAL |

|

| LEAKAGE CURRENT : | |

|

| DURING THE LAST 30 min. OF VIBRATION IN |

| |||

15 |

| EACH DIRECTION, THE CAPACITANCE SHALL | APPEARANCE : | |||

| BE MEASURED 3 TO 5 TIMES. | THERE SHALL BE NO EVIDENCE | ||||

|

| FOR OTHER PROCEDURES REFER TO IEC | OF MECHANICAL DAMAGE. . | |||

|

| Pub. |

|

|

| |

|

| MOUNTING METHOD |

| |||

SOLDER

ALUMINA

ALUMINA

BOARD

SCL Series