Performance impact

S.M.A.R.T. attribute data is saved to the disc so that the events that caused a predictive failure can be recre- ated. The drive measures and saves parameters once every two hours subject to an idle period on the

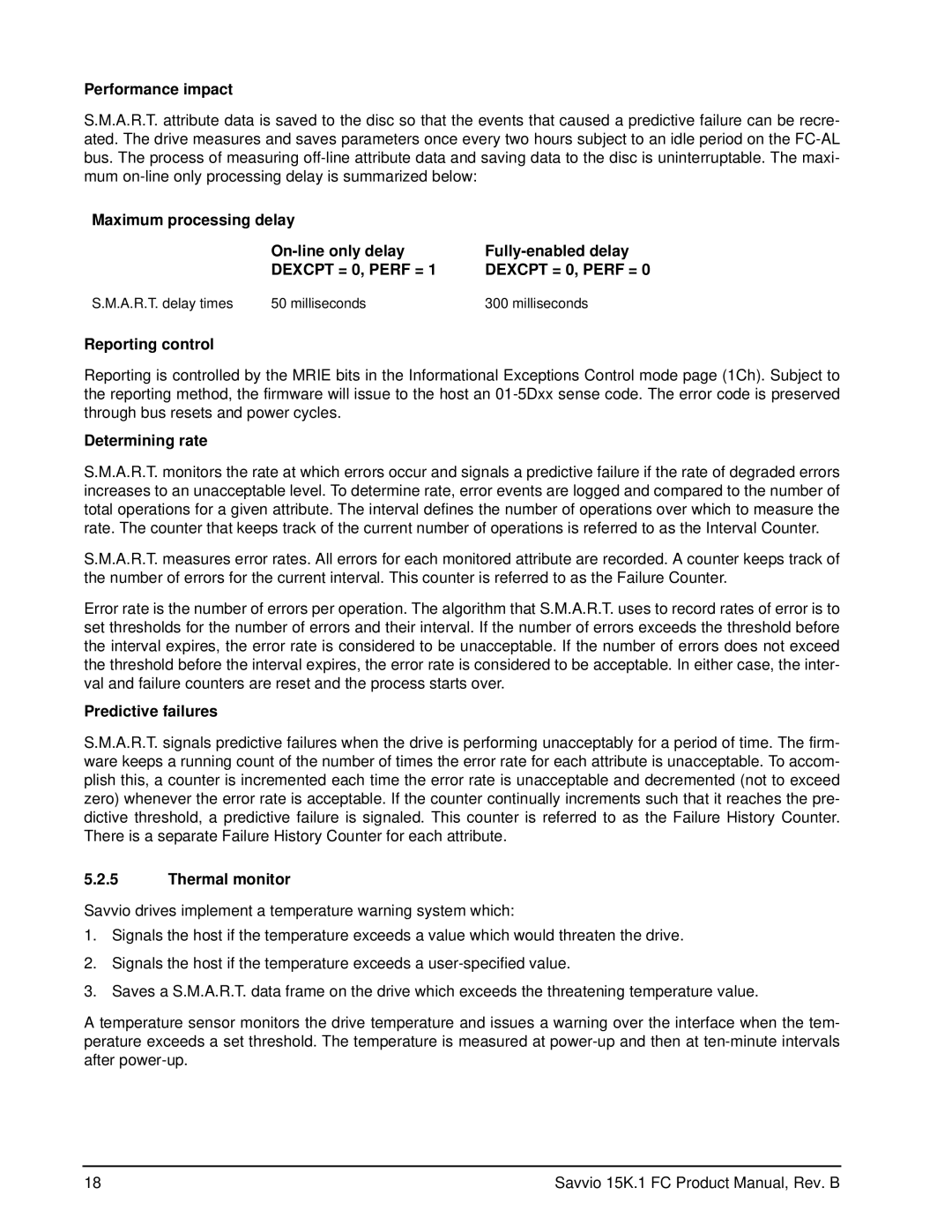

Maximum processing delay |

| |

| ||

| DEXCPT = 0, PERF = 1 | DEXCPT = 0, PERF = 0 |

S.M.A.R.T. delay times | 50 milliseconds | 300 milliseconds |

Reporting control

Reporting is controlled by the MRIE bits in the Informational Exceptions Control mode page (1Ch). Subject to the reporting method, the firmware will issue to the host an

Determining rate

S.M.A.R.T. monitors the rate at which errors occur and signals a predictive failure if the rate of degraded errors increases to an unacceptable level. To determine rate, error events are logged and compared to the number of total operations for a given attribute. The interval defines the number of operations over which to measure the rate. The counter that keeps track of the current number of operations is referred to as the Interval Counter.

S.M.A.R.T. measures error rates. All errors for each monitored attribute are recorded. A counter keeps track of the number of errors for the current interval. This counter is referred to as the Failure Counter.

Error rate is the number of errors per operation. The algorithm that S.M.A.R.T. uses to record rates of error is to set thresholds for the number of errors and their interval. If the number of errors exceeds the threshold before the interval expires, the error rate is considered to be unacceptable. If the number of errors does not exceed the threshold before the interval expires, the error rate is considered to be acceptable. In either case, the inter- val and failure counters are reset and the process starts over.

Predictive failures

S.M.A.R.T. signals predictive failures when the drive is performing unacceptably for a period of time. The firm- ware keeps a running count of the number of times the error rate for each attribute is unacceptable. To accom- plish this, a counter is incremented each time the error rate is unacceptable and decremented (not to exceed zero) whenever the error rate is acceptable. If the counter continually increments such that it reaches the pre- dictive threshold, a predictive failure is signaled. This counter is referred to as the Failure History Counter. There is a separate Failure History Counter for each attribute.

5.2.5Thermal monitor

Savvio drives implement a temperature warning system which:

1.Signals the host if the temperature exceeds a value which would threaten the drive.

2.Signals the host if the temperature exceeds a

3.Saves a S.M.A.R.T. data frame on the drive which exceeds the threatening temperature value.

A temperature sensor monitors the drive temperature and issues a warning over the interface when the tem- perature exceeds a set threshold. The temperature is measured at

18 | Savvio 15K.1 FC Product Manual, Rev. B |