operation

11 _ Turn down both ends to about I/2 inch diameter.

12.Smooth up with sandpaper,

13.Remove the workpiece from the Lathe and cut the ends off. Sand smooth.

14.Select a piece of wood

NOTE: When turning small diameters, some woods may

tend to *'chatter" or "vibrate" while cutting. If this _appens be sure to take very light cuts. Be sure the Spur Center is tightly seated into the workpiece.

1/2 iNCH DIAMETER

..........................- | i ullul, | ll | luu, |

MAKING THE SOUND BLOCK

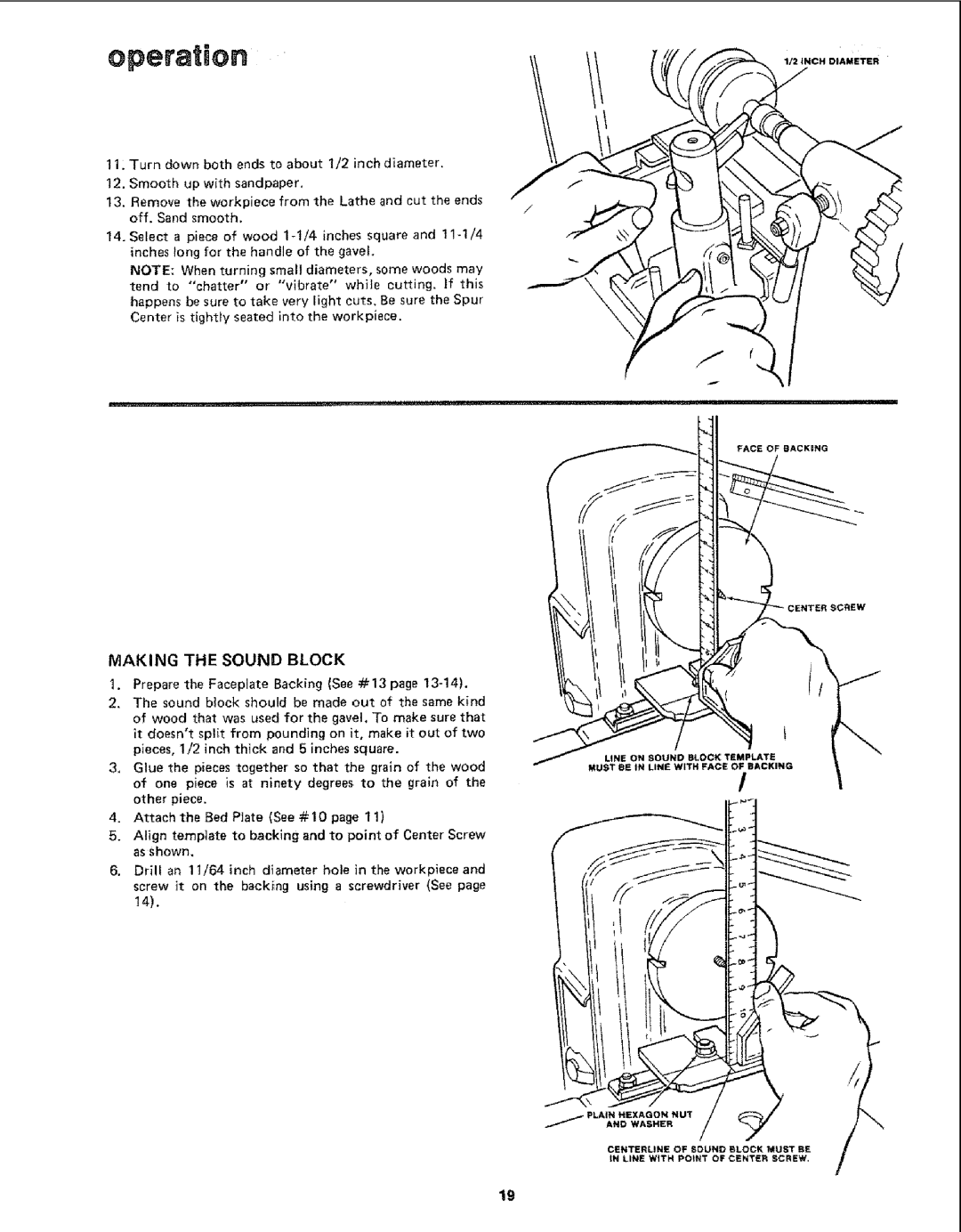

1.Prepare the Faceplate Backing (See @13 page

2, The sound block should be made out of the same kind of wood that was used for the gavel, To make sure that it doesn't split from pounding on it, make it out of two pieces, I/2 inch thick and 5 inches square.

3, Glue the pieces together so that the grain of the wood of one piece is at ninety degrees to the grain of the other piece.

4.Attach the Bed Plate (See #10 page 11}

5.Align temp]ate to backing and to pointof Center Screw as Shown,

6.Drill an 11/64 inch diameter hole in the workpiece and

screw it on the backing using a screwdriver (See page

14).

PLAIN HEXAGDN NUT

AND WASHER

CENTERLINE OF SOUND eLOCK MUST BE /

IN LINE W1TH POINT OF CENTER SCREW,

19