BASIC JOINTER---PLANER OPERATION

For your safety do not exceed a 1/16" deep cut on a planing operation for work pieces wider than

This

the machirie. To keep this system operating properly, the motor speed should be maintained. A feed rate that is too fast will slow

the motor down resulting in a poor cut and poor chip discharge. The type of wood, wood grain, and moisture content of the wood all affect an acceptable feed rate.

CAUTION: MAKE SURE ALL SIX BLADE LOCKING

,_SCREWSARE TIGHTENED SECURELY BEFORE AT- TEMPTING TO TURN THE MACHINE "ON" OR ATTEMPT- ING ANY OPERATION.

For your own safety, ALWAYS use hold down/push blocks when JOINTING wood that is NARROWER than 3 in. or when PLANING WOOD THAT IS THINNER than 3 in.

Do not plane, joint or bevel wood shorter than 12 in. Material this

short is more difficult to control while being cut. Small pieces of wood can tip over on the tables or into the cutterhead and can be kicked back toward you.

For best results, take light cuts. For average planing, jointing, or beveling, a cut between 1/32 and 1/16 in. deep will produce the best results.

FEEDING THE WORK PIECE

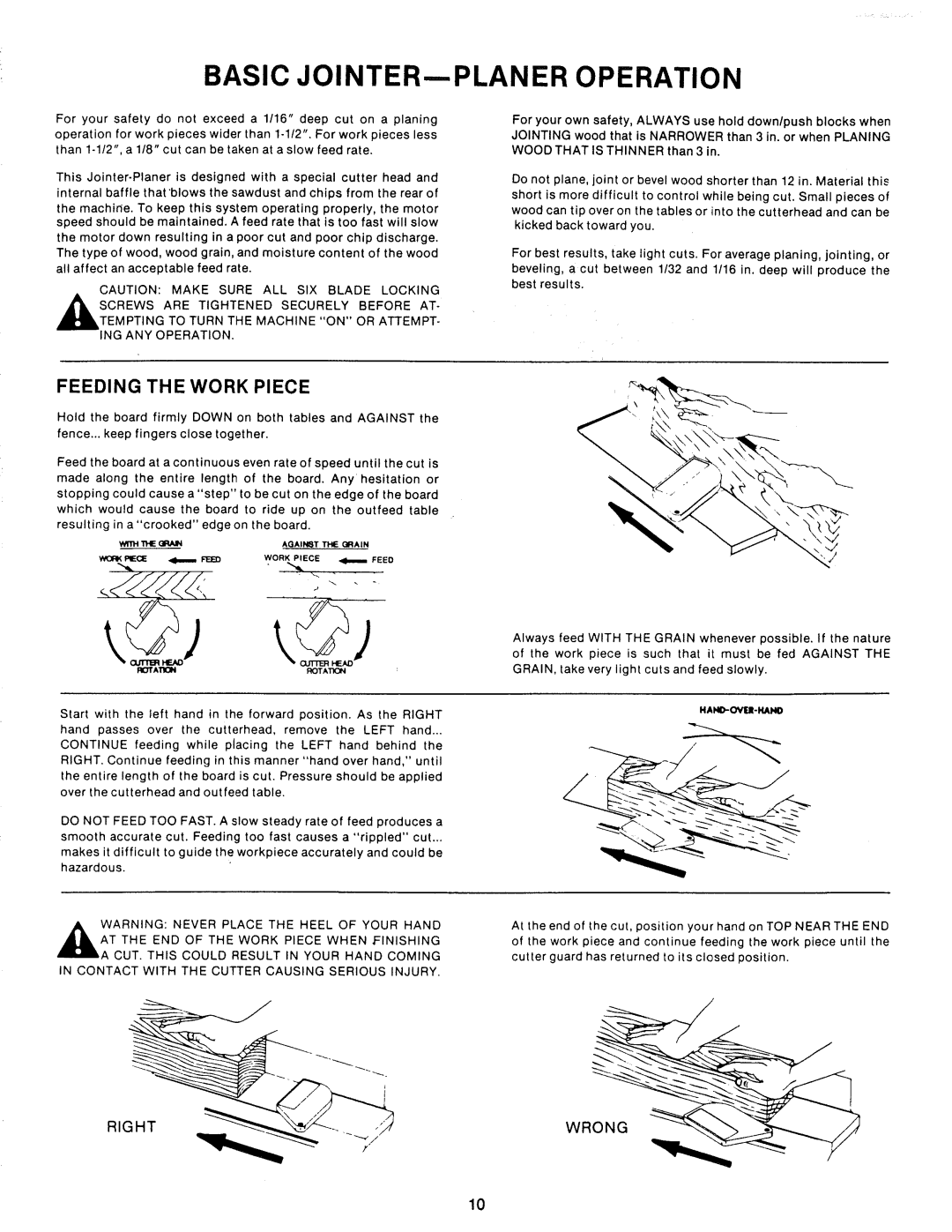

Hold the board firmly DOWN on both tables and AGAINST the fence.., keep fingers close together.

Feed the board at a continuous even rate of speed until the cut is

made along the entire length of the board. Any hesitation or\ stopping could cause a "step" to be cut on the edge of the board

which would cause the board to ride up on the outfeed table resulting in a "crooked" edge on the board.

WTTH THE | QRAJN |

| AGAIN6T _ | GRAIN |

WORK PIEQE | _ | F'IE]BD | WORK PIECE | <llu=m= FEED |

_A_ | RCrrAI"K_ |

Start with the left hand in the forward position. As the RIGHT

hand passes over the cutterhead, remove the LEFT hand...

CONTINUE feeding while placing the LEFT hand behind the RIGHT. Continue feeding in this manner "hand over hand," until the entire length of the board is cut. Pressure should be applied over the cutterhead and outfeed table.

DO NOT FEED TOO FAST. A slow steady rate of feed produces a

smooth accurate cut. Feeding too fast causes a "rippled" cut...

makes it difficult to guide the workpiece accurately and could be hazardous.

,_WARNING:NEVER PLACE THE HEEL OF YOUR HAND AT THE END OF THE WORK PIECE WHEN FINISHING A CUT. THIS COULD RESULT IN YOUR HAND COMING

IN CONTACT WITH THE CUTTER CAUSING SERIOUS INJURY.

Always feed WITH THE GRAIN whenever possible. If the nature of the work piece is such that it must be fed AGAINST THE GRAIN, take very light cuts and feed slowly.

At the end of the cut, position your hand on TOP NEAR THE END of the work piece and continue feeding the work piece until the cutter guard has returned to its closed position.

WRONG

),-

10