CHECKING CUTTER BLADES

POSITION AND CORD IS UNPLUGGED BEFORE PRO-

,_ CAUTION: MAKE SURE THE SWITCH IS IN THE OFF CEEDING WITH CHECKING CUTTER BLADES.

The blades in your

ever, may cause misalignment. For accurate cutting, the blades must

1.Block the cutter guard open with ascrap piece of wood about

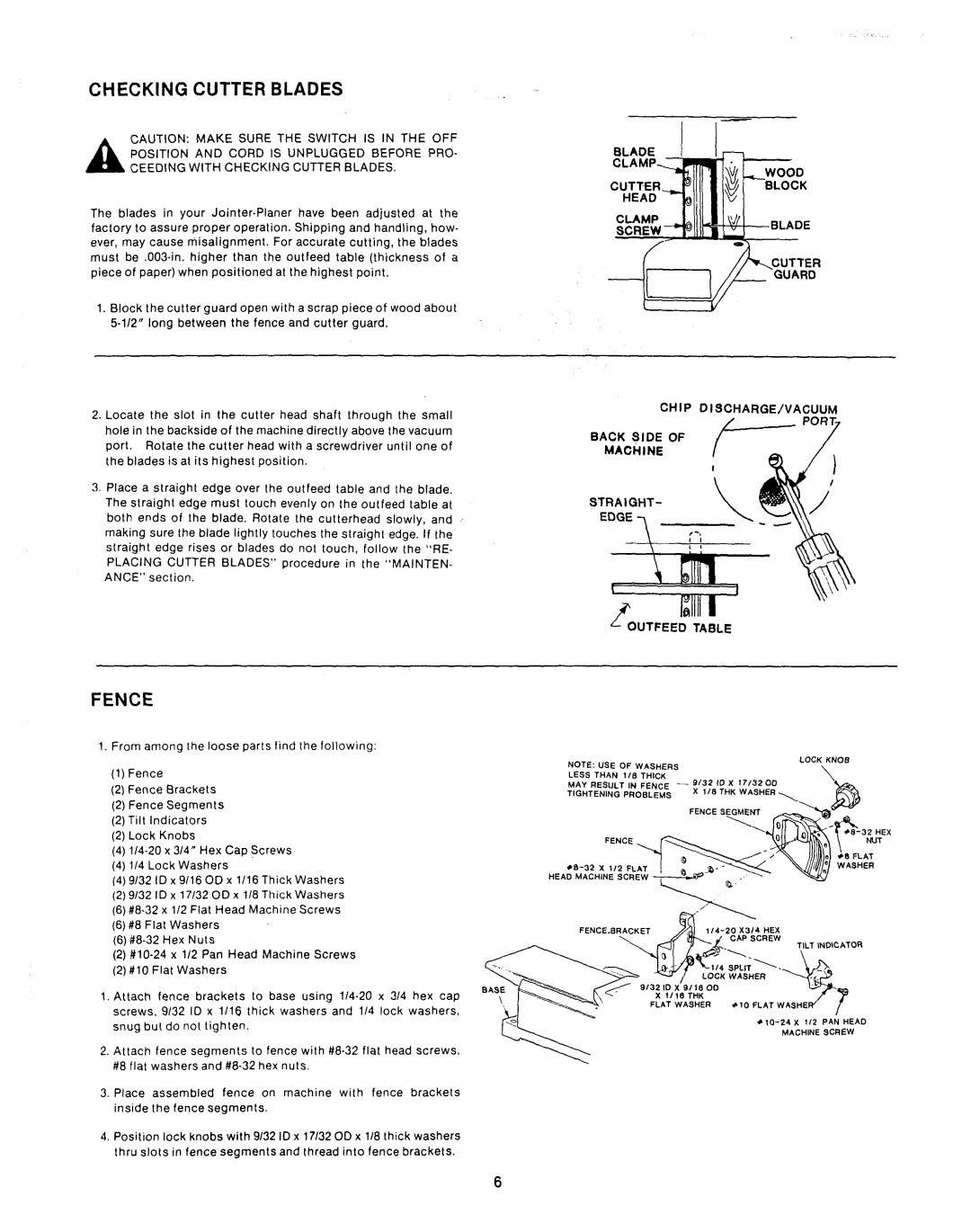

2.Locate the slot in the cutter head shaft through the small hole in the backside of the machine directly above the vacuum port. Rotate the cutter head with a screwdriver until one of the blades is at its highest position.

3.Place a straight edge over the outfeed table and the blade, The straight edge must touch evenly on the outfeed table at both ends of the blade. Rotate the cutterhead slowly, and making sure the blade lightly touches the straight edge. If the straight edge rises or blades do not touch, follow the "RE- PLACING CUTTER BLADES" procedure in the "MAINTEN.

ANCE" section.

FENCE

1.From among the loose parts find the following:

(1)Fence

(2)Fence Brackets

(2)Fence Segments

(2)Tilt Indicators

(2)Lock Knobs

(4)

(4)1/4 Lock Washers

(4)9/32 ID x 9/16 OD x 1/16 Thick Washers

(2)9/32 I D x 17/32 OD x 1/8 Thick Washers

(6)

(6)#8 Flat Washers (6)#8.32 Hex Nuts

(2)

(2)#10 Flat Washers

1.Attach fence brackets to base using

2.Attach fence segments to fence with

3.Place assembled fence on machine with fence brackets inside the fence segments,

4.Position lock knobs with 9/32 ID x 17/32 OD x 1/8 thick washers thru slots in fence segments and thread into fence brackets.

BLADE I

CUTTER..,,. i

HEAD

CLAMP

SCREW _

CHIP DISCHARGE/VACUUM

BACK SIDE OF

MACHINE

STRAIGHT-

EDGE ,

iltlI

_OUTFEED TABLE

|

|

|

|

|

|

| LOCK KNOB |

|

NOTE: | USE | OF | WASHERS |

|

|

| _. |

|

LESS | THAN | 1/8 | THICK |

|

|

| \, |

|

MAY | RESULT | IN | FENCE | 9/32 | I0 X | fT/32OO |

| |

TIGHTENING | PROBLEMS |

| X 1/8 | THK | W |

| ||

|

|

|

|

| FENCE | SEGMENT |

| |

|

|

|

|

|

|

| HEX | |

| FENCE |

|

|

|

|

| NUT | |

|

|

|

|

|

|

| ÷B FLAT | |

X 112 FLAT |

|

|

| WASHER |

| |||

HEAD MACHINE | SCREW |

|

|

|

|

| ||