OPERATION

DEPTH OF CUT

As previously mentioned, the depth of cut is importantbe- cause it affectsthe rate of feed which, in turn, affectsthe

qualityof a cut (and, also, the possibilityof damageto your routermotorand bit).A deepcut requiresa slowerfeed than a shallowone, and a too deep cut willcauseyouto slowthe

feed so muchthatthe bit isno longercutting,it is scraping, instead.

DEPTH OF CUT

Makinga deep cut is never advisable.The smallerbits--

especiallythose only 1/16 inch in diameter

thatyoudo not exceed 1/8 inchdepthofcutin a singlepass, regardlessof the bit size or the softnessor conditionof the

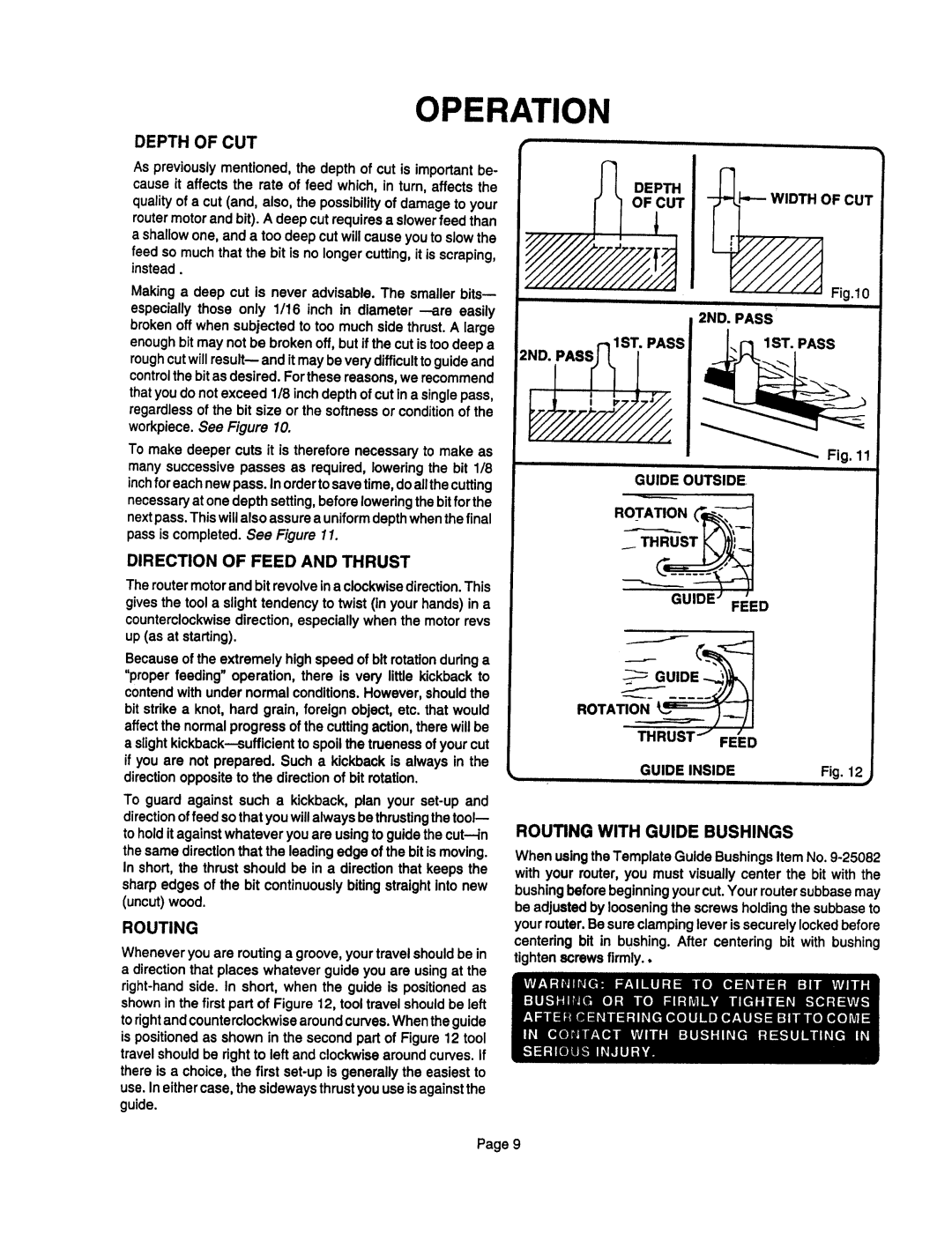

workpiece.See Figure 10.

To make deeper cuts it is therefore necessaryto make as many successivepasses as required,loweringthe bit 1/8 inchfor eachnewpass. In ordertosavetime,doallthecutting necessaryat one depthsetting,beforeloweringthebitfor the nextpass.Thiswillalso assurea uniformdepthwhenthefinal passis completed.See Figure 11.

DIRECTION OF FEED AND THRUST

The routermotorand bit revolvein a clockwisedirectionThis. givesthe toola slighttendencyto twist(In yourhands)in a counterclockwisedirection,especiallywhen the motorrevs up (as at starting).

Becauseofthe extremelyhighspeed of bit rotationduringa "proper feeding" operation, there is very little kickbackto contendwith undernormal conditionsHowever,shouldthe. bit strikea knot,hard grain, foreign object, etc. that would affectthe normalprogressofthe cuttingaction,therewillbe a

To guard against such a kickback,plan your

the same directionthat the leadingedge ofthe bitis moving. In short,the thrustshould be in a directionthat keepsthe sharpedges of the bit continuouslybitingstraightintonew (uncut)wood.

ROUTING

Wheneveryou are routinga groove,yourtravelshouldbe in

adirectionthat places whatever guide you are usingat the

torightandcounterclockwisearoundcurves.Whentheguide ispositionedas shown in the secondpart of Figure12 tool travelshouldbe rightto leftand clockwisearoundcurves.If there is a choice,the first

Fig.10

2ND. PASSJ I / | I _L_ |

GUIDE OUTSIDE,

_ TH_Eoo

jou,o

THRUST" FEED

GUIDE INSIDE | Fig. 12 |

i

ROUTING WITH GUIDE BUSHINGS

When usingtheTemplateGuideBushingsItemNo.

Page 9