H

MAINTENANCE

A good maintenance program of regular inspec- tion and care will increase the service life and help

to maintain the safety and performance of your

saw.

•Make all adjustments or repairs (except car- buretor adjustments) with:

spark plug wire disconnected

engine cool as opposed to a unit that has just been run.

GUIDE BAR AND CHAIN

IncreaSe the service life of your Guide Bar and

in this manual.-_

tion. |

|

1. CHAIN MAINTENANCE | _: |

•Sharpen the chain when: =

about the size of the teeth of the chain.

|

|

|

| ROUND |

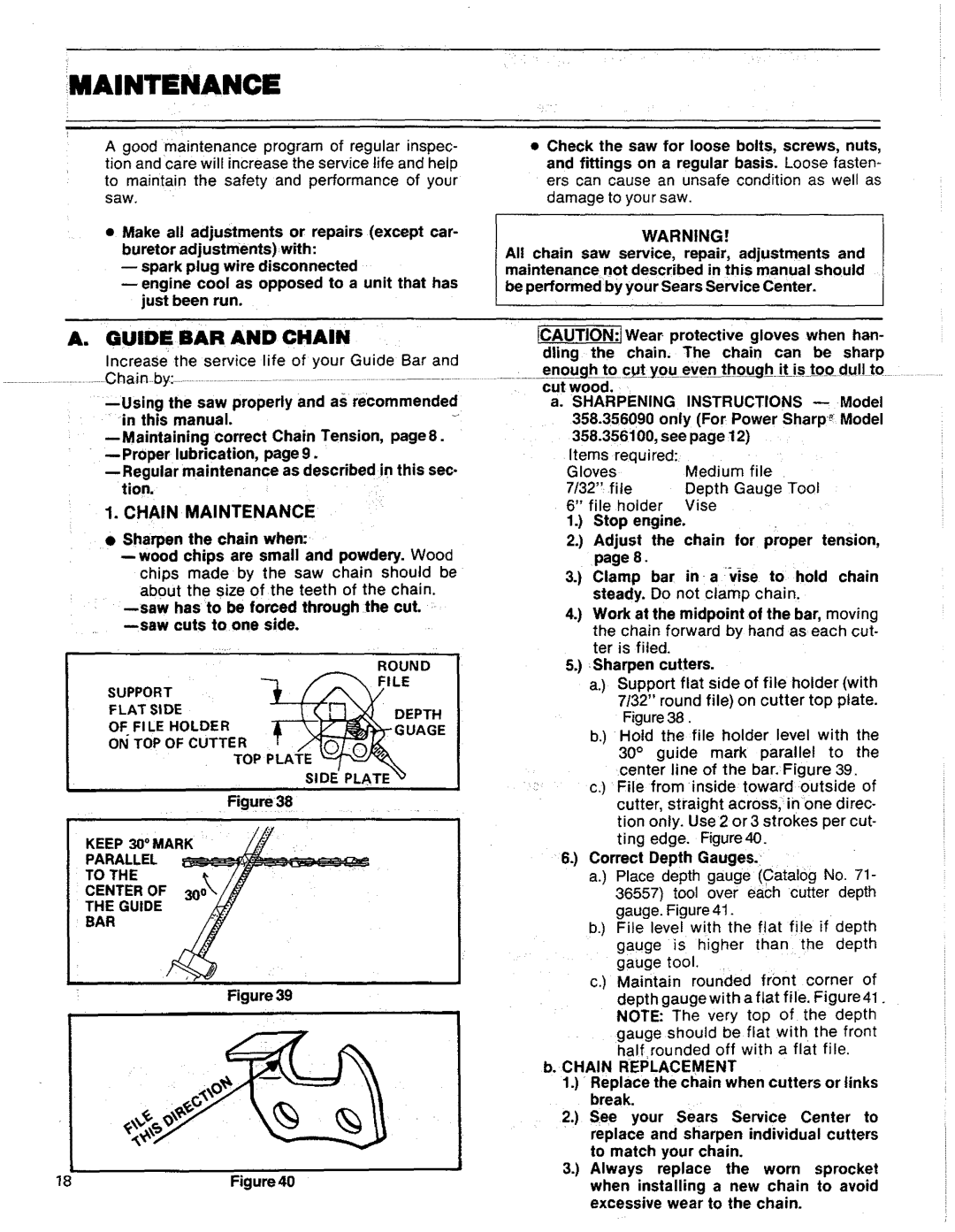

SUPPORT | = | _ | _ | FILE |

_ |

| _// | ||

FLAT SIDE | _ | _ |

| _ DEPTH |

OF FILE HOLDER | _GUAGE |

| ||

O1_TOP OF CUTTER | T | __ |

| |

TOP PLA]'E

'. .. SIDE PLATE

KEEP 30° MARK

PARALLEL

TO TH E

CENTER OF

THE GUIDE

BAR

Figure 39

18 | Figure 40 |

L¸: _ : | . | , |

•Check the saw for loose bolts, screws, nuts,

and fittings on a regular basis. Loose fasten- ers can cause an unsafe condition as well as

damage to your saw.

All chain saw service, repair, adjustments and

maintenance not described in this manual should

WARNING!t

be performed by your Sears Service Center.

[CAUTION:i Wear protective gloves when han-

dling the chain, The chain can be sharp

a. SHARPENING INSTRUCTIONS

358.356090 only (For Power Sharp_i Model

358.356100, |

| see page 12) .... | ||

Items required: |

| |||

Gloves |

| Medium | file . | |

7!32". file |

| Depth | Gauge Tool | |

6" file holder | Vise |

| ||

1.) | Stop engine. |

| ||

2.) | Adjust | the chain for proper tension, | ||

| page 8. |

|

|

|

3.) | Clamp | bar in | ||

steady. Do not clamp chain.

4.) Work at the midpoint of the bar, moving

the chain forward by hand as each cut- ter is filed.

| 5.) Sharpen | cutters. | |

| a.) Support flat side of file holder (with | ||

| 7/32" round file) on cutter top plate. | ||

| Figure38. |

| |

| b.) Hotd the file holder level with the | ||

| 30 ° guide mark parallel to the | ||

| .center line of the bar.Figure 39. | ||

": ;_.: | c.) _File | from | inside toward outside of |

| cutter, straight across, _in one direc- | ||

| tion only. Use 2 or 3 strokes per cut- | ||

| ting edge. | Figure40. | |

6.) Correct Depth Gauges. .....

a.) Place depth gauge(Catal0g No. 71- 36557) tool over each cutter depth gauge. Figure 41.

b.) FiJe level with the fiat fiJe if depth

gauge is higher than the depth gauge tool.

c.) Maintain rounded front corner of

depth gauge with a fiat file. Figure41. NOTE: The very top of the depth

gauge should be flat with the front half rounded off with a flat file.

b. CHAIN REPLACEMENT

1.)_ Replace the chain when cutters or links break.

2.) See your Sears Service Center to replace and sharpen individual cutters to match your chain.

3.) Always replace the worn sprocket when installing a new chain to avoid excessive wear to the chain.