ADJUSTMENTS

Treadbelt Adjustment

The TREADBELT (12) has been factory

TREADBELT ADJUSTMENT SCREW (56) by using the ALLEN WRENCH (70) provided. ALLEN WRENCH

Step 1. If TREADBELT has moved to right,tighten right TREADBELT ADJUSTMENT SCREW 1/2 turn using ALLEN

WRENCH, while TREADMILL is running and no one is on it. The TREADBELT should move towards left.

Step 2. Let TREADMILL run several turns of TREADBELT and note any sideways movement.

Step 3. If only a small amount of change occurred, loosen left TREADBELT ADJUSTMENT SCREW 1/2 turn using

ALLEN WRENCH.

Step 4. Repeat step 2.

Step 5. Repeat steps 1 through 4 until TREADBELT is centered and remains there during use. If TREADBELT has moved to LEFT, follow steps

NOTE: ff TREADBEL T is slipping it will be necessary to tighten both TREADBEL T ADJUSTMENT SCREW until slipping has stopped. It may then be necessary to repeat steps 1 through 4 for alignment.

_D_L_L_'. | DO NOT OVERTIGHTEN TREADBEL 7".Overtightening is denoted by curling of |

| the edges of the TREADBEL T. |

Reed Switch Adjustment

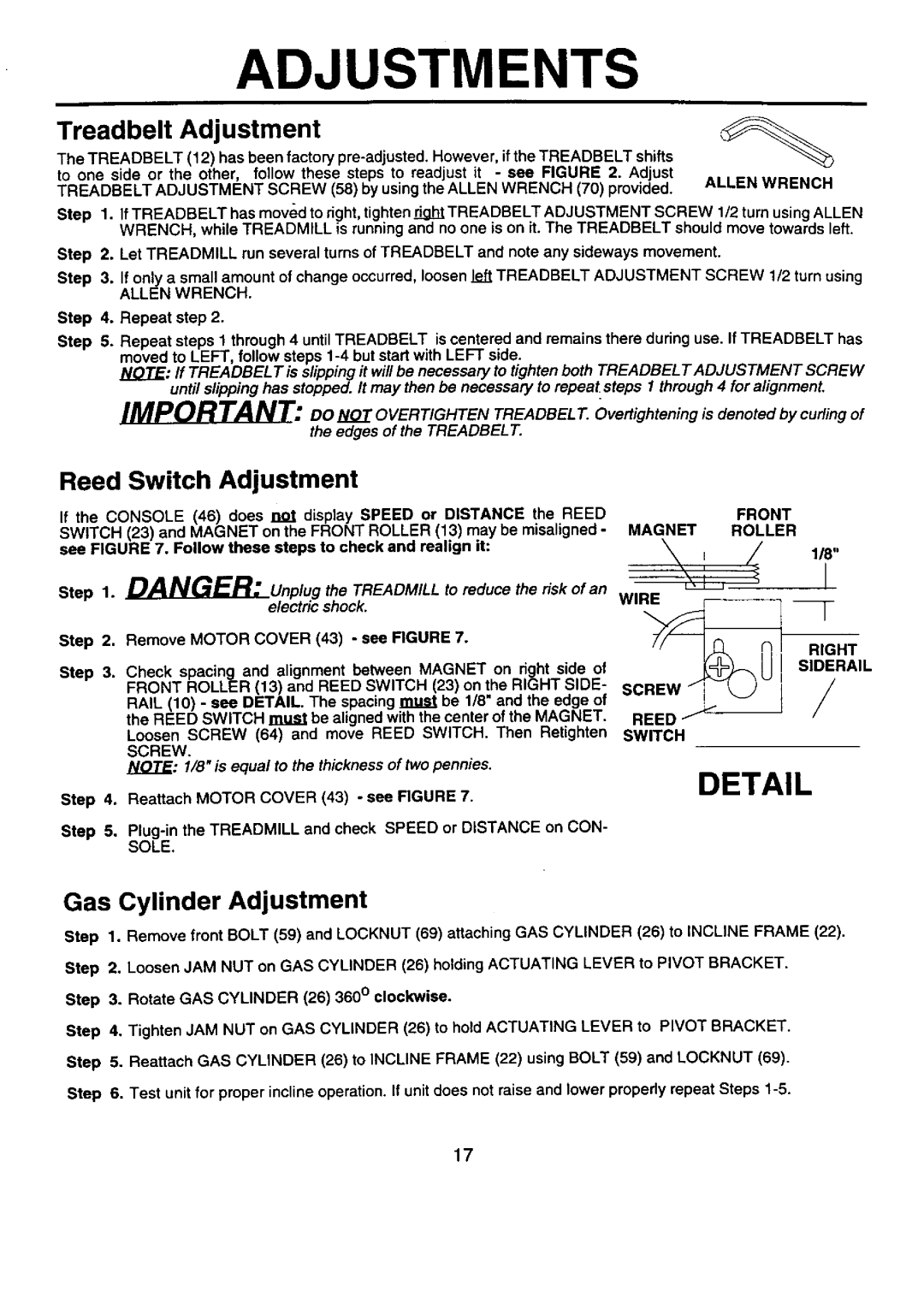

If the CONSOLE (46) does not display SPEED or DISTANCE the REED

SWITCH (23) and MAGNET on the FRONT ROLLER (13) may be misaligned - see FIGURE 7. Follow these steps to check and realign it:

Step 1. _L__Unplug | the TREADMILL to reduce the risk of an |

| electric shock. |

Step 2, Remove MOTOR COVER (43) - see FIGURE 7.

Step 3. Check spacing and alignment between MAGNET on right side of FRONT ROLLER (13) and REED SWITCH (23) on the RIGHT SIDE- RAIL (10) - see DETAIL. The spacing must be 1/8" and the edge of the REED SWITCH must be aligned with the center of the MAGNET.

Loosen SCREW (64) and move REED SWITCH. Then Retighten

SCREW.

NOTE: 1/8" is equal to the thickness of two pennies.

Step 4. Reattach MOTOR COVER (43) - see FIGURE 7.

Step 5.

SOLE.

FRONT

MAGNET ROLLER

/ 118"

I

WIREF

RIGHT

0 SlDERAIL/

REED/J _----

SWITCH

DETAIL

Gas Cylinder Adjustment

Step 1. Remove front BOLT (59) and LOCKNUT (69) attaching GAS CYLINDER (26) to INCLINE FRAME (22).

Step 2. Loosen JAM NUT on GAS CYLINDER (26) holding ACTUATING LEVER to PIVOT BRACKET.

Step 3. Rotate GAS CYLINDER (26) 360 ° clockwise.

Step 4. Tighten JAM NUT on GAS CYLINDER (26) to hold ACTUATING LEVER to PIVOT BRACKET.

Step 5. Reattach GAS CYLINDER (26) to INCLINE FRAME (22) using BOLT (59) and LOCKNUT (69).

Step 6. Test unit for proper incline operation. If unit does not raise and lower properly repeat Steps

17