CUSTOMER RESPONSIBILITIES

LUBRICATION

•Hex Shaft and Gears - Hex shait and gears require no lubrication. All bearings and bushings =t? lifetime lubricated and require no maintenance (See FIG. 3).

NOTE: Any greasing or oiling of the above components can cause contamination of the friction wheel. If the disc

drive plate or friction wheel come in contact with grease or oil, damage to the fdction wheel will result.

Should grease or oil come in contact with the disc drive plate or friction wheel, be sure to clean the plate and wheel

thoroughly.

NOTE: For storage, the hex shaft and gears should be

wiped with

Auger Gear Box - The auger gear box has been factory lubricated for life. If for some reason lubricant should leak out, have the auger gear case checked by a competent repairman.

I

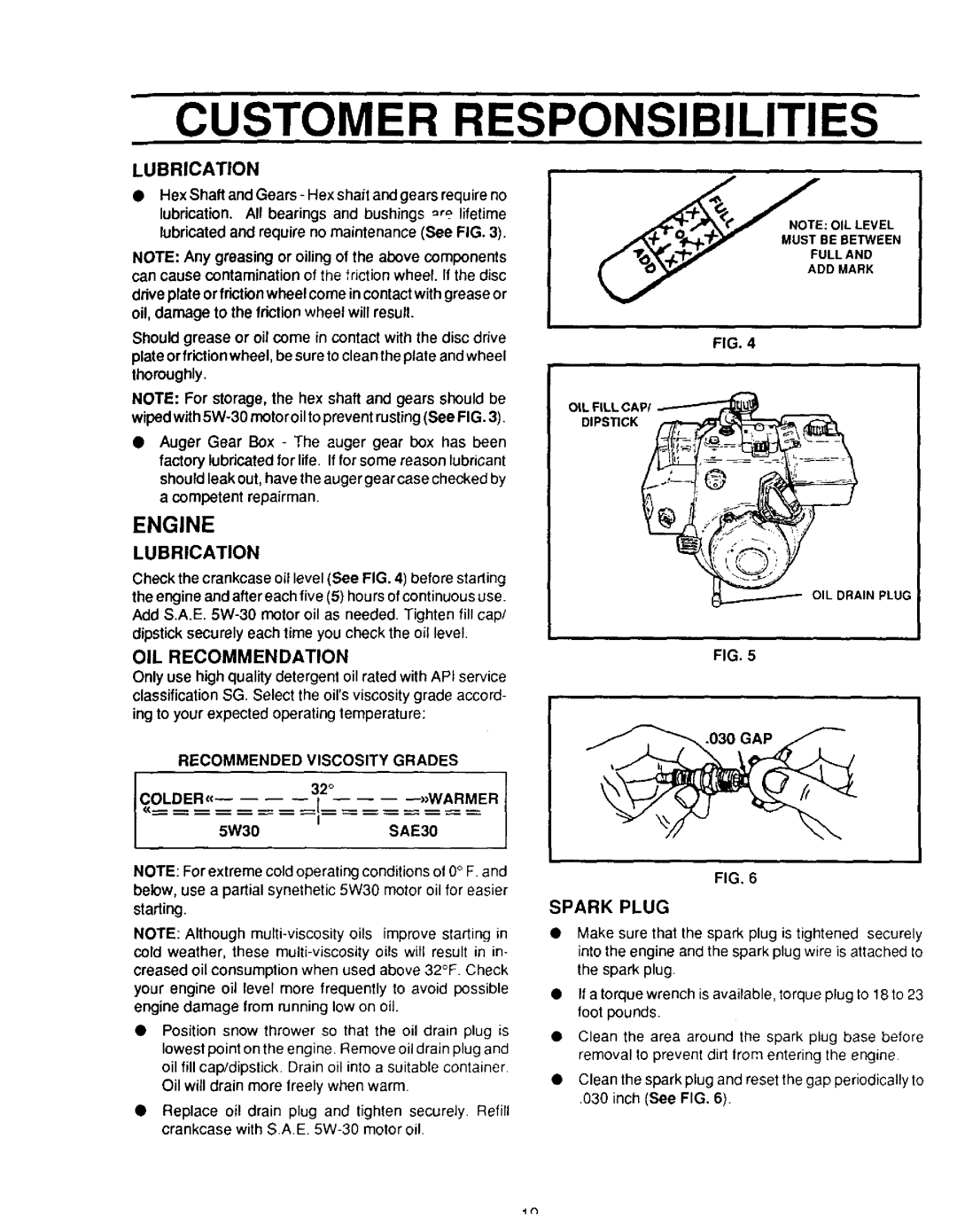

NOTE: OIL LEVEL I

MUST BE BETWEEN

FULLAND

ADD MARK

FIG. 4

OIL FILL CAP/

DIPSTICK

ENGINE

LUBRICATION

Check the crankcase oil level (See FIG. 4) before starting the engine and after each five (5) hou rs of continuous use. Add S.A.E.

OIL RECOMMENDATION

Only use high quality detergent oil rated with API service classification SG. Select the oil'sviscosity grade accord- ing to your expected operating temperature:

RECOMMENDED VISCOSITY GRADES

COLDER_<-- i2 °--_>WARMER

5W30SAE30

NOTE: For extreme cold operating conditions of 0° F. and below, use a partial synethetic 5W30 motor oil for easier starting.

NOTE: Although

Position snow thrower so that the oil drain plug is lowest point on the engine. Remove oil drain plug and oil fill cap/dipstick. Drain oil into a suitable container Oil will drain more freely when warm.

•Replace oil drain plug and tighten securely. Refill crankcase with S.AE.

OIL DRAIN PLUG

FIG. 5

.030 GAP

FIG. 6

SPARK PLUG

•Make sure that the spark plug is tightened securely into the engine and the spark plug wire is attached to the spark plug.

•If a torque wrench is available, torque plug to 18 to 23 foot pounds.

•Clean the area around the spark plug base before removal to prevent dirt from entering the engine

•Clean the spark plug and reset the gap periodically to

.030 inch (See FIG. 6).

'4(3