ASSEMBLY

Bend the ends of the cotter pin around the rod and reinstall the plastic cap.

Tighten the eye bolt installed earlier, keeping eye in line with the rod while tightening the inside securely

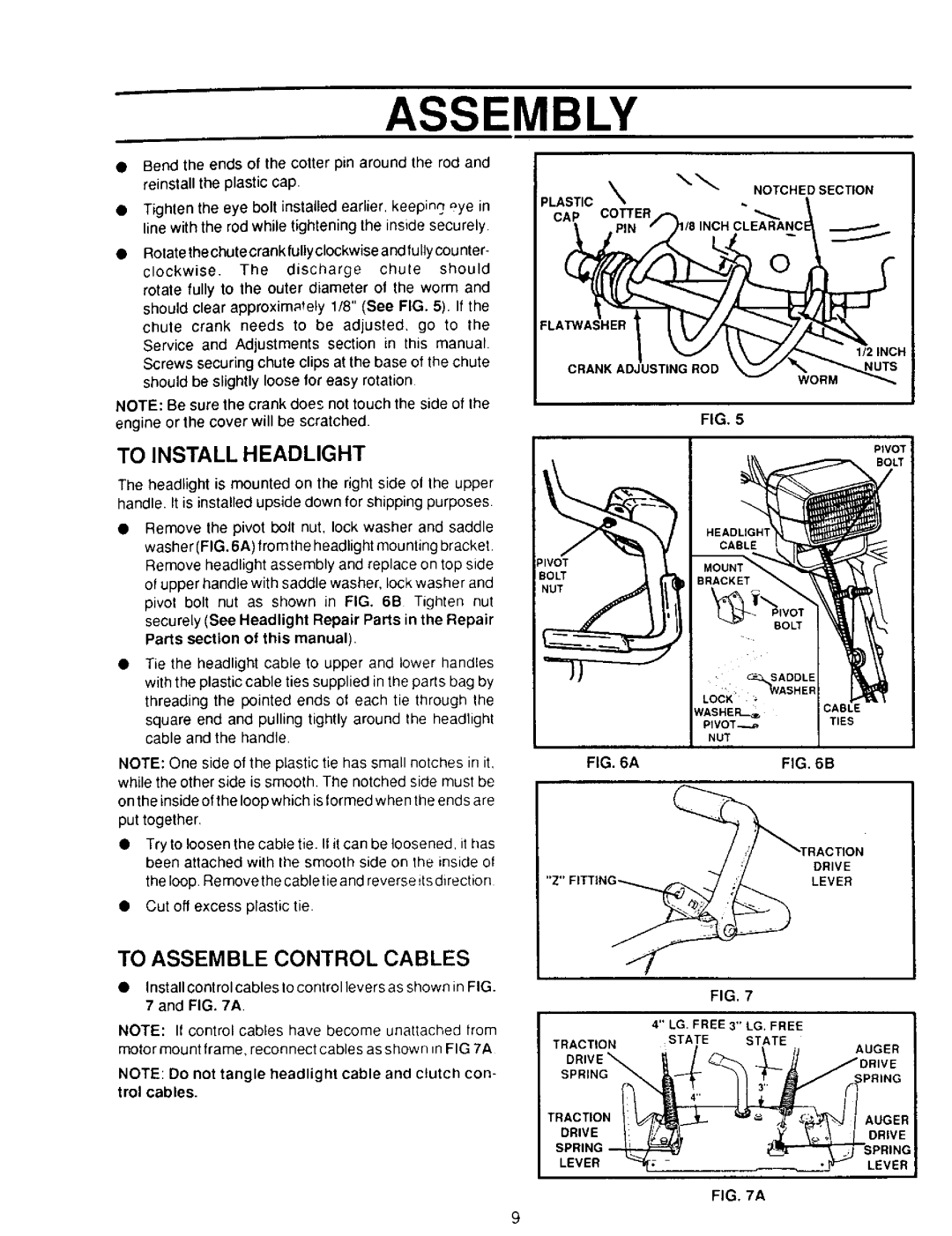

Rotate the chute crank fully clockwise and tullycou nter-

clockwise. The discharge chule should rotate fully to the outer diameter of the worm and should clear approximately 1/8" (See FIG. 5). If the chute crank needs to be adjusted, go to the Service and Adjustments section in this manual• Screws securing chute clips at the base of the chute should be slightly loose for easy rotation

NOTE: Be sure the crank does not touch the side of the engine or the cover will be scratched.

TO INSTALL HEADLIGHT

The headlight is mounted on the right side of the upper handle. It is installed upside down for shipping purposes•

Remove the pivot bolt nut, lock washer and saddle washer (FIG. 6A) from the headlight mounting bracket• Remove headlight assembly and replace on top side of upper handle with saddle washer, lock washer and pivot bolt nut as shown in FIG. 6B Tighten nut securely (See Headlight Repair Parts in the Repair

Parts section of this manual).

Tie the headlight cable to upper and lower handles with the plastic cable ties supplied in the parts bag by threading the pointed ends ot each tie through the

square end and pulling tightly around the headlight cable and the handle.

NOTE: One side of the plastic tie has small notches in it, while the other side is smooth. The notched side must be on the inside of the loop which is formed when the ends are put together,

•Try to loosen the cable tie. Ifit can be loosened, it has been attached with the smooth side on the inside ol

the loop• Re move the cable tie and reverse its direction

•Cut off excess plastic tie.

PLASTIC\ | . NOTCHEDSECTION |

CAP COTTER | _. |

| _1/8INCH CLEARANC |

FLATWASHER 1 | 1/2 INCH |

CRANK ADJUSTING ROD | WORM |

|

FIG. 5

i

PtVOT;

BOLT

•

•='_ASH E R

LOCK | - |

CABLE | |

TIES | |

NUT |

|

FIG. 6A | FIG. 6B |

DRIVE

LEVER

TO ASSEMBLE CONTROL CABLES

•Install control cables tocontrol levers as shown in FIG. 7 and FIG. 7A.

NOTE: If control cables have become unattached from motor mount frame, reconnect cables as shown _nFIG 7A

NOTE: Do not tangle headlight cable and clutch con- trol cables.

|

| FIG. | 7 |

|

|

|

|

| 4" LG. FREE 3" LG. FREE |

|

|

| |||

TRACTION | STATE | STATE | iJ |

| AUGER | ||

DRIVE_ | : | / | t | /DRIVE | |||

_/ | _ | _L__ |

|

|

| ||

SPRING | m,,_)_J_- | _! | :' A_""_ | R |

| PRING | |

|

| 4,, |

|

|

|

|

|

DRIVE | I: [_'Q"[J_, | ,.¥ | _;o\ | I | DRWE | ||

SPRING | _ |

| p RI NG | ||||

LEVER | ""_ • |

| _ |

|

|

| LEVER |

FIG. 7A

9