MAINTENANCE

MAINTENANCE

CUTTER SHAFT

Routinely inspect cutter shaft for and replace any worn or damaged blades. When replacing worn blades always replace blade set directly opposite, (180 degrees) otherwise cutter shaft will be out of balance. Inspect bushing and bolt for wear and replace if necessary. Remove any debris which may become entangled around cutter shaft or bearings. Stop machine at first sign of excessive vibration and inspect cutter shaft and bearings.

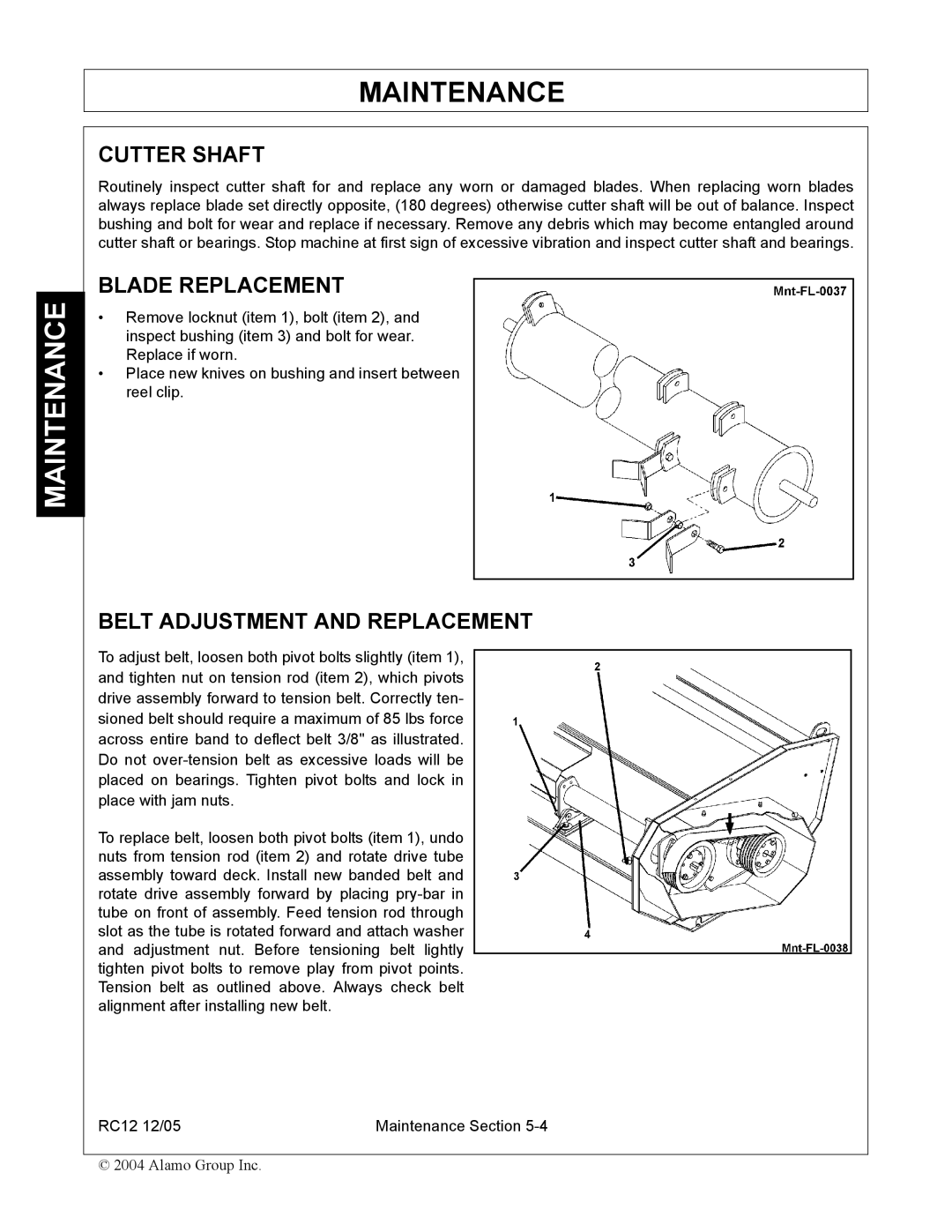

BLADE REPLACEMENT

•Remove locknut (item 1), bolt (item 2), and inspect bushing (item 3) and bolt for wear. Replace if worn.

•Place new knives on bushing and insert between reel clip.

BELT ADJUSTMENT AND REPLACEMENT

To adjust belt, loosen both pivot bolts slightly (item 1), and tighten nut on tension rod (item 2), which pivots drive assembly forward to tension belt. Correctly ten- sioned belt should require a maximum of 85 lbs force across entire band to deflect belt 3/8" as illustrated. Do not

To replace belt, loosen both pivot bolts (item 1), undo nuts from tension rod (item 2) and rotate drive tube assembly toward deck. Install new banded belt and rotate drive assembly forward by placing

RC12 12/05 | Maintenance Section |

© 2004 Alamo Group Inc.