MAINTENANCE

MAINTENANCE

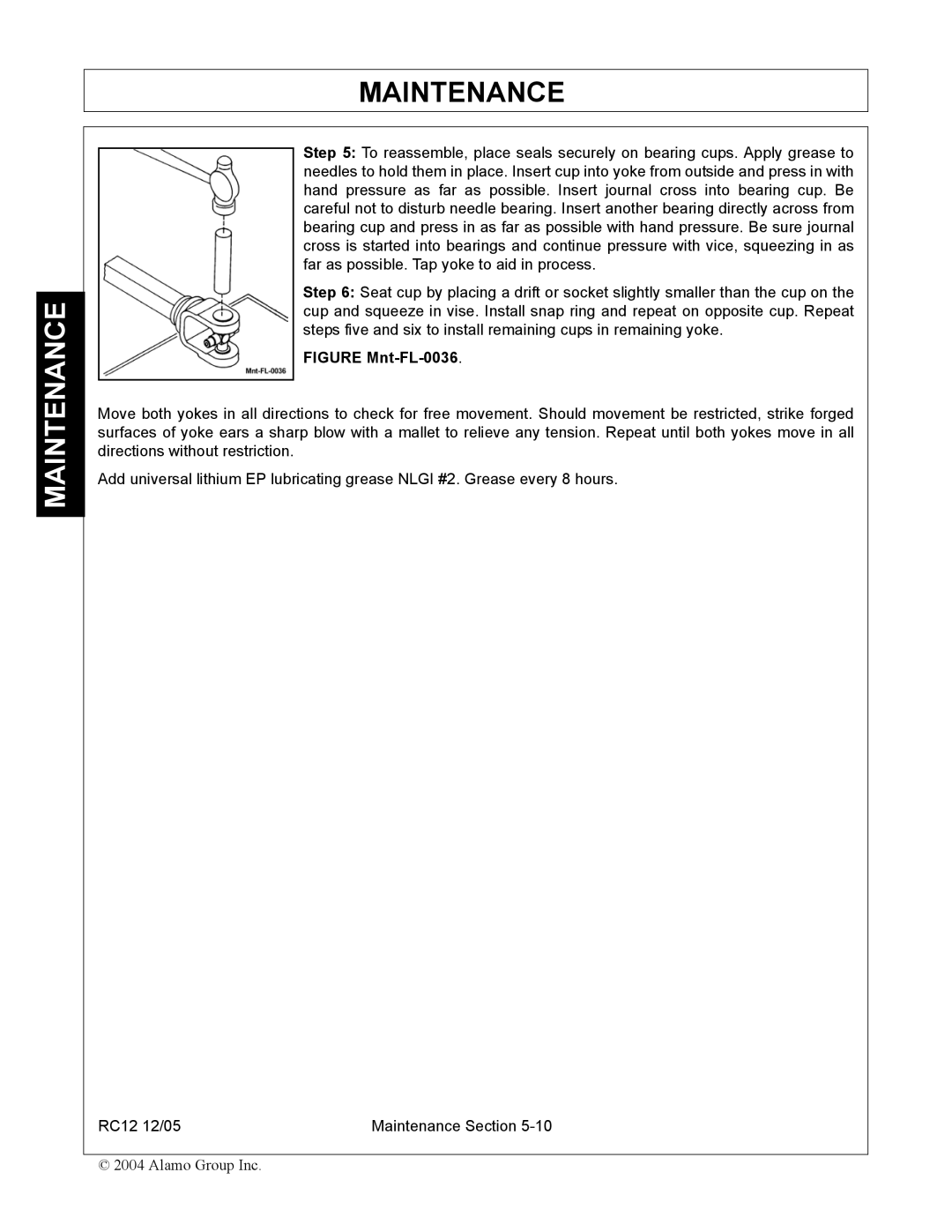

Step 5: To reassemble, place seals securely on bearing cups. Apply grease to needles to hold them in place. Insert cup into yoke from outside and press in with hand pressure as far as possible. Insert journal cross into bearing cup. Be careful not to disturb needle bearing. Insert another bearing directly across from bearing cup and press in as far as possible with hand pressure. Be sure journal cross is started into bearings and continue pressure with vice, squeezing in as far as possible. Tap yoke to aid in process.

Step 6: Seat cup by placing a drift or socket slightly smaller than the cup on the cup and squeeze in vise. Install snap ring and repeat on opposite cup. Repeat steps five and six to install remaining cups in remaining yoke.

FIGURE Mnt-FL-0036.

Move both yokes in all directions to check for free movement. Should movement be restricted, strike forged surfaces of yoke ears a sharp blow with a mallet to relieve any tension. Repeat until both yokes move in all directions without restriction.

Add universal lithium EP lubricating grease NLGI #2. Grease every 8 hours.

RC12 12/05 | Maintenance Section |

© 2004 Alamo Group Inc.