MAINTENANCE |

| PRESSURE | ||

Removal of Soot from Heating Coil: | Burner Nozzle: |

| ||

In the heating process, fuel residue in the form of soot | Keep the tip free of surface deposits by wiping it with a | |||

deposits may develop between the heating coil pipe, | clean, solvent saturated cloth, being careful not to plug | |||

and block air flow which will affect burner combustion. | or enlarge the nozzle. For maximum efficiency, replace | |||

WASHER | ||||

When soot has been detected on visual observation, | the nozzle each season. |

| ||

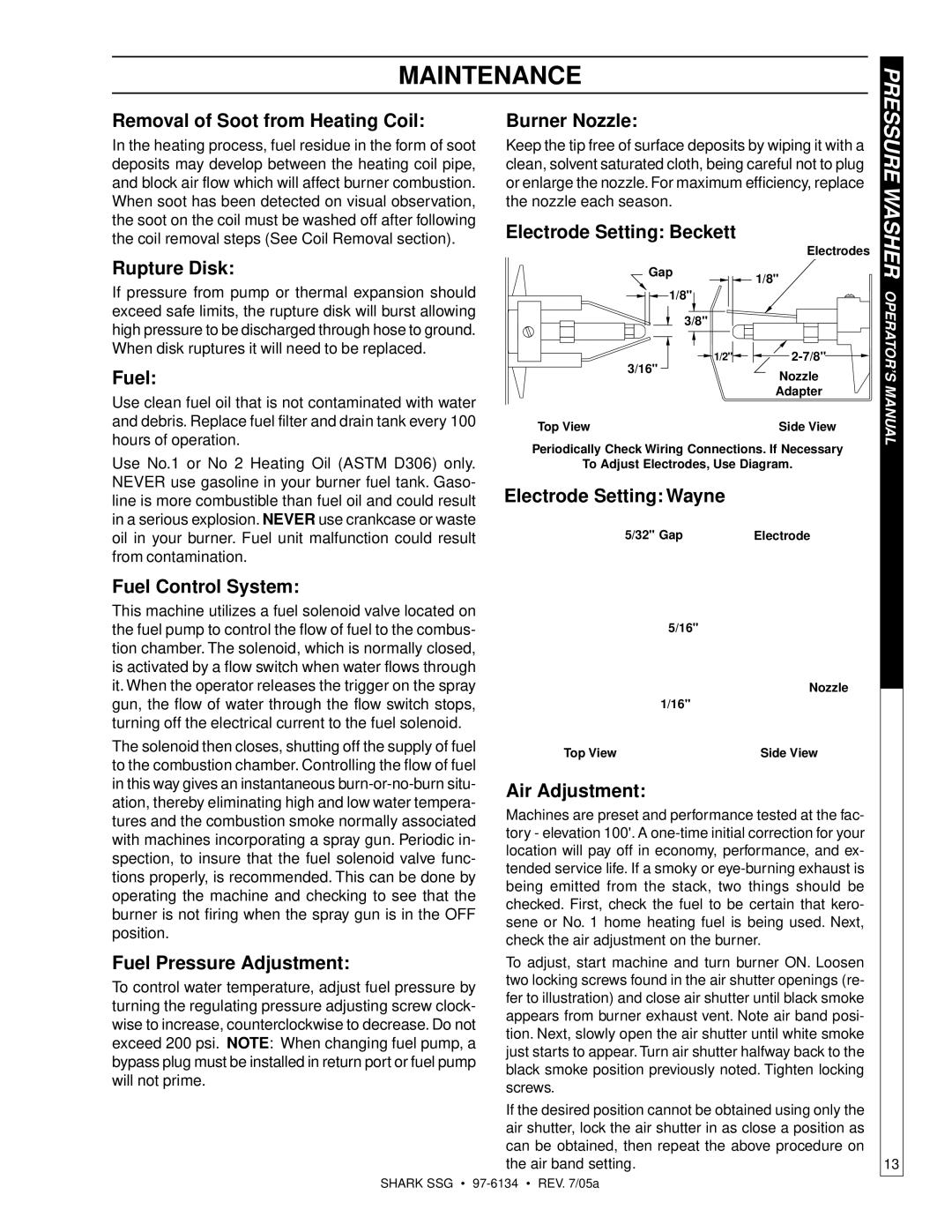

the soot on the coil must be washed off after following | Electrode Setting: Beckett |

| ||

the coil removal steps (See Coil Removal section). |

| |||

| Electrodes | |||

Rupture Disk: |

| |||

Gap | 1/8" | |||

If pressure from pump or thermal expansion should |

|

| ||

1/8" |

| OPERATOR’S | ||

exceed safe limits, the rupture disk will burst allowing | 3/8" |

| ||

high pressure to be discharged through hose to ground. |

| |||

|

| |||

When disk ruptures it will need to be replaced. | 1/2" | |||

| ||||

Fuel: | 3/16" | Nozzle | ||

| ||||

Use clean fuel oil that is not contaminated with water |

| Adapter | MANUAL | |

|

| |||

and debris. Replace fuel filter and drain tank every 100 | Top View | Side View | ||

hours of operation. | ||||

Periodically Check Wiring Connections. If Necessary | ||||

Use No.1 or No 2 Heating Oil (ASTM D306) only. |

| |||

To Adjust Electrodes, Use Diagram. |

| |||

NEVER use gasoline in your burner fuel tank. Gaso- | Electrode Setting: Wayne |

|

| |

line is more combustible than fuel oil and could result |

|

| ||

in a serious explosion. NEVER use crankcase or waste | 5/32" Gap | Electrode |

| |

oil in your burner. Fuel unit malfunction could result |

| |||

from contamination. |

|

|

| |

Fuel Control System: |

|

|

| |

This machine utilizes a fuel solenoid valve located on |

|

|

| |

the fuel pump to control the flow of fuel to the combus- |

| 5/16" |

| |

tion chamber. The solenoid, which is normally closed, |

|

|

| |

is activated by a flow switch when water flows through |

|

|

| |

it. When the operator releases the trigger on the spray |

| Nozzle |

| |

|

| |||

gun, the flow of water through the flow switch stops, |

| 1/16" |

| |

turning off the electrical current to the fuel solenoid. |

|

|

| |

The solenoid then closes, shutting off the supply of fuel | Top View | Side View | ||

to the combustion chamber. Controlling the flow of fuel | ||||

|

|

| ||

in this way gives an instantaneous | Air Adjustment: |

|

| |

ation, thereby eliminating high and low water tempera- |

|

| ||

Machines are preset and performance tested at the fac- | ||||

tures and the combustion smoke normally associated | ||||

tory - elevation 100'. A | ||||

with machines incorporating a spray gun. Periodic in- | ||||

location will pay off in economy, performance, and ex- | ||||

spection, to insure that the fuel solenoid valve func- | ||||

tended service life. If a smoky or | ||||

tions properly, is recommended. This can be done by | ||||

being emitted from the stack, two things should be | ||||

operating the machine and checking to see that the | ||||

checked. First, check the fuel to be certain that kero- | ||||

burner is not firing when the spray gun is in the OFF | ||||

sene or No. 1 home heating fuel is being used. Next, | ||||

position. | ||||

check the air adjustment on the burner. | ||||

| ||||

Fuel Pressure Adjustment: | To adjust, start machine and turn burner ON. Loosen | |||

To control water temperature, adjust fuel pressure by | two locking screws found in the air shutter openings (re- | |||

fer to illustration) and close air shutter until black smoke | ||||

turning the regulating pressure adjusting screw clock- | ||||

appears from burner exhaust vent. Note air band posi- | ||||

wise to increase, counterclockwise to decrease. Do not | ||||

tion. Next, slowly open the air shutter until white smoke | ||||

exceed 200 psi. NOTE: When changing fuel pump, a | ||||

just starts to appear. Turn air shutter halfway back to the | ||||

bypass plug must be installed in return port or fuel pump | ||||

black smoke position previously noted. Tighten locking | ||||

will not prime. | ||||

screws. |

|

| ||

|

|

| ||

| If the desired position cannot be obtained using only the | |||

| air shutter, lock the air shutter in as close a position as | |||

| can be obtained, then repeat the above procedure on | |||

| the air band setting. | 13 | ||

SHARK SSG •