AS-Interface

Introduction

Transmission technology

Overview Transmission method

Benefits

Process or field communication

Configuration examples

Operating modes

System components

System components

Overview

More information

Technical specifications

Technical specifications

Technique

A/B technique concept

AS-Interface master Communication cycle

Addressing A/B slaves

CP 343-2 P

Selection and Ordering data

Design

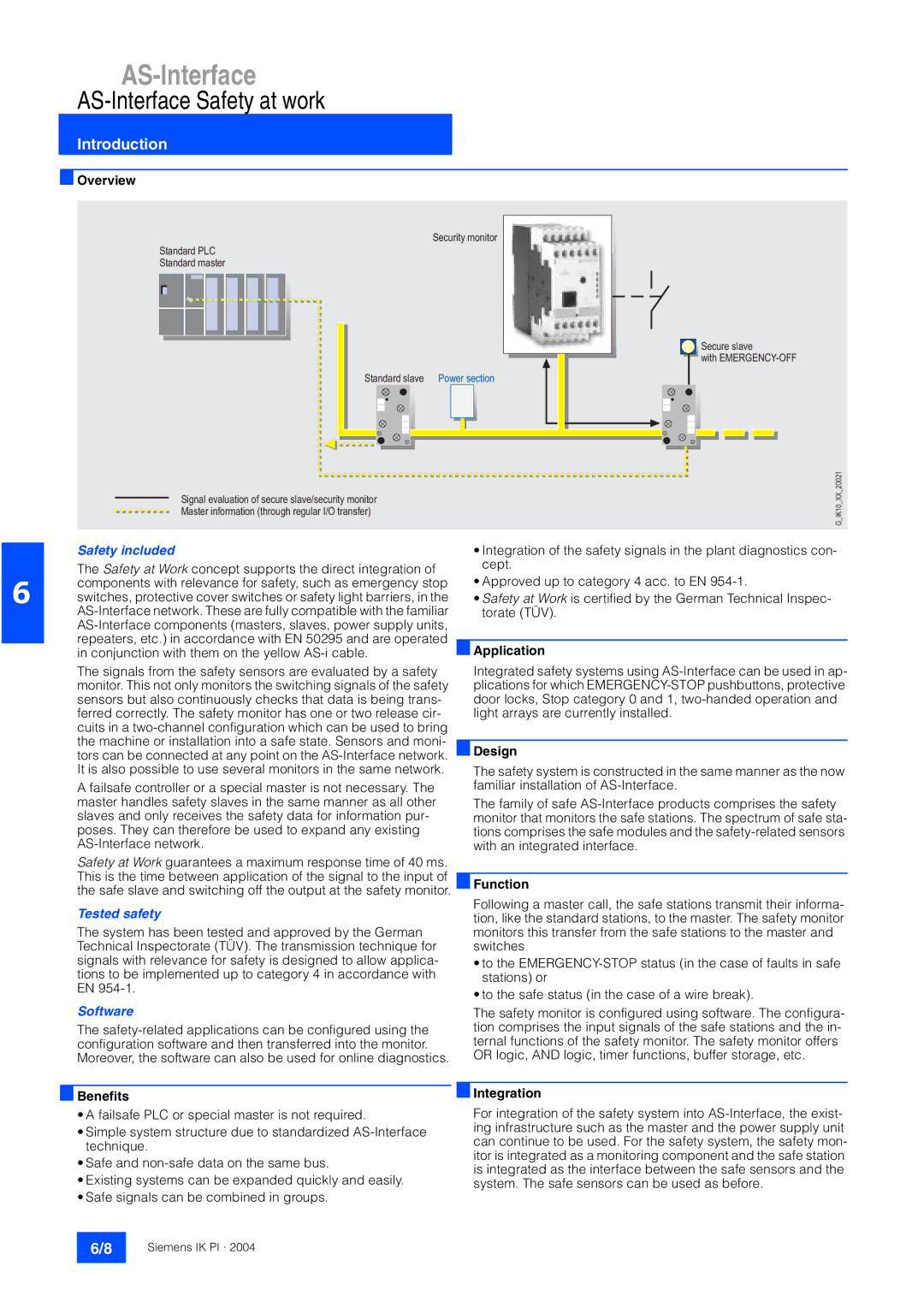

AS-Interface Safety at work

Safety included

Tested safety

Introduction

AS-Interface safety monitors

Dimensional drawings

PNP

AS-Interface safe compact modules

SAP

UL, CSA

Design Order No K45F safe compact module 3RK1 205-0BQ00-0AA3

3RK1 901-1KA01

Schematics

Socket Assignment / data sheet / function

Logical assignments

K45F Safe Compact Module

AS-Interface position switches

Position switch with separate actuator

Position switch with tumbler

Overview Application

AS-Interface position switch, standard, with M12 connector

Design Order No

3SF3 200-6XX03-0BA1

3SF3 200-6XX04-0BA1

3SF3 243-0XX00-0BA1

3SF3 243-0XX40-0BA1

AS-Interface cable-operated switches

Specifications

AS-Interface cable-operated switch

3SF2 150-1BF00-0BA1

Standards

AS-Interface light curtains and light arrays for Category

Overview Benefits

Transmitter/receiver synchronization

3SF7 842-6BB00

3SF7 842-6BB01

3SF7 842-6BC00

3SF7 842-6BC01

Siguard Standard Light Curtain, 90 mm resolution

3SF7 842-6EE00

3SF7 842-6EE01

3SF7 842-6EF00

Design Order No Siguard Light Array

3SF7 842-6SE00

3SF7 842-6SE01

3SF7 842-6PG00

Accessories

AS-Interface laser scanner LS4

Further applications

Function principle

LS4Soft operating software

3SF7 834-6DD00

Pack 3RX9 307-0AA00

PIN1 PIN2 PIN3

PIN

LS4 laser scanner

AS-Interface Emergency Stop pushbuttons

Masters for Simatic S5

User interface

Ordering data

Parameter assignment

Masters for Simatic S7

Overview Design

Profibus

6GK7 142-2AH00-0XA0

Overview Application

6GK7 243-2AX01-0XA0

Mode of operation

For connection of Simatic S7-300

CP 343-2 P

CP 343-2 P 6GK7 343-2AH10-0XA0 Communications processor

Modules for operation in the field

LED diagnostic indication of the K60 compact module

Digital I/O modules IP67 K60

K60 compact modules with up to eight digital inputs

K60 compact module

K60 mounting plate

New products

AS-Interface Slaves

AS-Interface Slaves

Are not required Siemens IK PI ·

Design Order No Digital I/O modules IP67 K60

AS-Interface M12 sealing caps 3RK1 901-1KA00

Distributor 3RK1 901-1NN00

Sealing kit 3RK1 902-0AR00

Terminal assignment, input, pnp M12 socket

IN1 IN2

Terminal assignment, output, pnp M12 socket

Singlecable

Addressing

Digital I/O modules IP68 / IP69K K60R

Mounting

Connection

IP68 / IP69K tests

Inputs/4 outputs IP68 / IP69K

3RK1 400-1CR00-0AA3

IP67 round cable distributor

AS-i / Uaux Ribbon cable for

M12, passive without LED

3RK1 901-1NR00

Modules for operation in the field

Digital I/O modules IP67 K45

Mounting possibilities

For 3RK2 400-1BQ20-0AA3 Umin = 16.5

Put in a DC 12 / DC 13 typ

Cable, contacted through Grated seal seal shaped

Design Order No Digital I/O modules IP67 K45

K45 mounting plate

3RK1 901-1PN00

Cable end piece 3RK1 901-1MN00

Distributor 3RK1 901-1NN00 Siemens IK PI ·

Terminal assignment input, pnp M12 socket

Terminal assignment input, pnp M8 socket

Terminal assignment output, pnp M12 socket 24 V DC

Digital I/O modules IP67 application modules

Advantages of the K45 compact modules

Application module decoding table K45

Application module Comparison type K45 Order No Design

PNP NPN

EMI

EMI Eemi

1 input/1 output

3RG9 001-0AJ00

Fold distributor passive

Without LED

3RG9 001-0CB00

Operating voltage in accordance 26.5 to

Dimensional drawings Application modules

Coupling modules

Modules for operation in the field

Analog I/O modules IP67 K60

Design Order No Analog I/O modules IP67 K60

3RK1 207-1BQ40-0AA3

3RK1 107-1BQ40-0AA3

3RK1 207-3BQ40-0AA3

Pin assignment input module

Pin assignment output module

Pneumatic I/O modules

Order informationen of Kuhnke GmbH

Modules for operation in IP20 control cabinet

PCB

LED diagnostics indication

Modules for operation in IP20 control cabinet

SlimLine Series

F90 module

Features

SlimLine

SlimLine modules of Series S22.5 and S45

Removable terminals

Technical specifications common to all SlimLine modules

Releasing removable terminals

Customer benefits

Locking removable terminals

SlimLine S22.5

IN1

IN2

IN3

OUT1

OUT2

IN1 OUT1

IN2 OUT2

OUT1 OUT3

OUT2 OUT4

SlimLine S45

IN1/OUT1

IN2/OUT2

IN3/OUT3

200

AS-Interface Slaves

IN4

SlimLine S22.5 module

SlimLine S45 module

Sealable cap 3RP1

Plug-in lugs 3RP1

Typical circuit diagram for SlimLine S22.5

Typical circuit diagram for SlimLine S45

Module F90

Eeee

Built-in via terminal screws

Total current input in mA Input connection

AS-Interface Slaves

Dimensional drawings Schematics

Combicon connector set 3RX9 810-0AA00

Terminal assignment

Design Order No F90 module

Flat module

Design Order No Flat module 3RK1 400-0CE00-0AA3

Special integrated solutions

AS-Interface communication modules

OUT1 OUT2 OUT3 OUT4

Connection Connection pad

IN1 IN2 IN3 IN4

Supply via AS

With gold-plated

Design Order No Inputs / 4 outputs

3RK1 400-0CD00-0AA3

3RK1 400-0CD01-0AA3

3RK1 400-1CD00-0AA2

Modules with special functions

Counter modules

Modules with special functions

Design Order No Counter module

Earth fault detection modules

100

101

102

Installation guidelines Nominal discharge current isn

Overvoltage protection module

103

Protection level Up

104

Overvoltage protection module 3RK1 901-1GA00

105

AS-Interface motor starters and IP65/67 load feeders

AS-Interface compact starters IP65 400 V AC

Display characteristics

106

Outputs

107

Inputs

DO1

Tripped signal

108

109

DS/RS EDS/ERS

110

Connector set for power infeed, 9-pole

111

112

Connector pin assignment digital inputs Y assignment

Connector pin assignment power connector

AS-Interface motor starters IP67 24 V DC

113

Quick stop function

Brake

114

115

Ecofast motor and soft starter

116

AS-Interface motor starters and IP20 load feeders

AS-Interface load feeder modules IP20

117

AS-Interface load feeder module

118

Inputs

119

120

Typical control circuits

Sirius soft starters

121

Design Order No Sirius Soft Starter

AS-Interface load feeder module

122

Signum pushbuttons and indicator lights

AS-Interface F-Adapter for Emergency Stop command devices

AS-Interface enclosure

123

AS-Interface enclosure

AS-Interface customized enclosures and front panel modules

124

Options

125

AS-Interface front panel module

Order form for AS-Interface housing

126

Order form AS-Interface front panel modules

Configuration

127

128

129

130

Code for design/key removal position of locks

131

132

AS-Interface LED displays

133

Each LOGO! now connectable to the AS-Interface system -new

AS-Interface for Logo

134

Earth fault detection

135

Power supply units IP20

136

CE, UL, CSA

137

3RX9 305-1AA00 3RX9 306-1AA00

138

35 15 mm and S7 rail 35 x 7.5 mm Special function

Dual output 4 a

Design Order No AS-Interface IP20 power supply unit

139

140

135 54,6 105

Power supply units IP65

141

142

Single output 230 AC 3RX9 311-0AA00 24 DC 6EP1 632-1AL01

Transmission media

AS-Interface shaped cable

143

TPE special version

144

System components and accessories

Repeater/Extender

145

Benefits Repeaters

146

Design Repeaters

AS-Interface addressing and diagnostic unit

Addressing units

147

3RK1 904-2AB01

Addressing cable with jack plug Z231A

Addressing cable with M12 female connector 3RX1

148

Online statistics

Diagnostic units

149

150

Trace modus Test report

Miscellaneous accessories

151

Documentation

Brochures

152

Way distributor