SMC sierra monitor corporation | Sentry Instruction Manual - Version 6 |

7.8 HYDROGEN SULFIDE MODULE

7.8.1 DESCRIPTION

Model

The sensor assembly includes a reuseable housing and disposable electrochemical sensor. The assembly screws into one hub of the sensor module enclosure and plugs into the bottom electronics card via a six pin connector.

Cabling from the controller connects to a three pin spring loaded terminal strip on the electronics assembly.

7.8.2 TROUBLE ANALYSIS

Electrical adjustment, or replacement of the sensor will be necessary under the following conditions:

•Controller displays the following error messages

|

|

|

| SENSOR FAILURE |

|

|

|

|

|

|

|

|

|

| |||

|

|

|

| LOW SENSITIVITY |

|

|

|

|

|

|

|

|

|

| |||

| • |

|

|

|

|

|

|

|

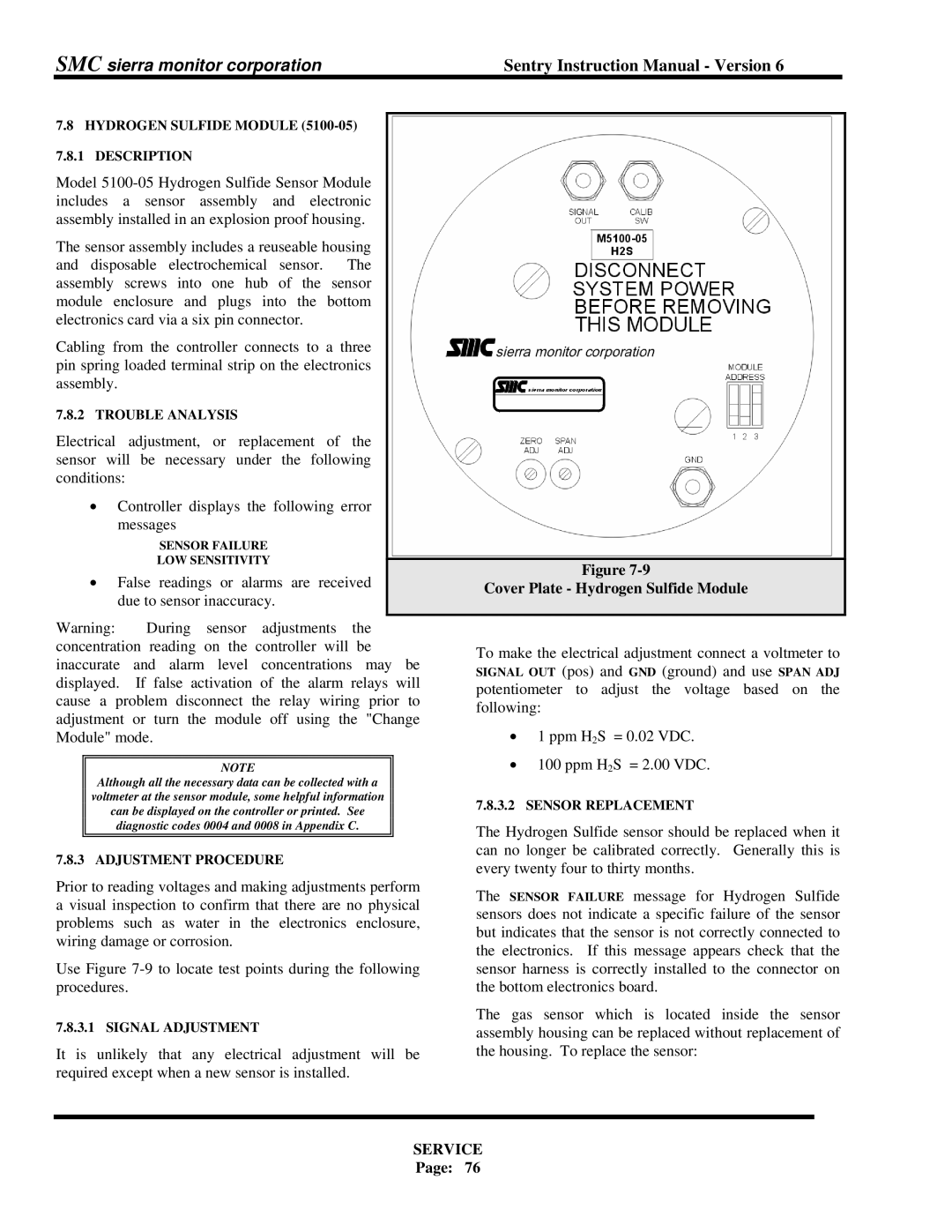

| Figure |

|

|

| ||||

| False | readings | or alarms are received |

|

|

|

|

|

| ||||||||

|

|

| Cover Plate - Hydrogen Sulfide Module |

|

| ||||||||||||

|

| due to sensor inaccuracy. |

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||||

Warning: |

| During sensor | adjustments | the |

|

|

|

|

|

|

| ||||||

concentration reading on the | controller will | be |

| To make the electrical adjustment connect a voltmeter to | |||||||||||||

inaccurate | and | alarm | level | concentrations | may | be | |||||||||||

SIGNAL OUT (pos) and GND (ground) and use SPAN ADJ | |||||||||||||||||

displayed. | If false activation of | the alarm relays will | |||||||||||||||

potentiometer to adjust the voltage | based | on the | |||||||||||||||

cause a | problem disconnect | the | relay wiring prior | to | |||||||||||||

following: |

|

|

| ||||||||||||||

adjustment or turn the module off using the "Change |

|

|

| ||||||||||||||

• | 1 ppm H2S = 0.02 VDC. |

|

|

| |||||||||||||

Module" mode. |

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| • | 100 ppm H2S = 2.00 VDC. |

|

|

| ||

|

|

|

|

| NOTE |

|

|

|

|

|

|

|

| ||||

| Although all the necessary data can be collected with a |

|

|

|

|

|

|

| |||||||||

| voltmeter at the sensor module, some helpful information |

|

| 7.8.3.2 | SENSOR REPLACEMENT |

|

|

| |||||||||

| can be displayed on the controller or printed. See |

|

|

|

|

| |||||||||||

|

| diagnostic codes 0004 and 0008 in Appendix C. |

|

| The Hydrogen Sulfide sensor should be replaced when it | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||||

7.8.3 ADJUSTMENT PROCEDURE |

|

|

|

| can no longer be calibrated correctly. | Generally this is | |||||||||||

|

|

|

| every twenty four to thirty months. |

|

|

| ||||||||||

Prior to reading voltages and making adjustments perform |

|

|

| ||||||||||||||

The SENSOR FAILURE message for Hydrogen | Sulfide | ||||||||||||||||

a visual inspection to confirm that there are no physical | |||||||||||||||||

sensors does not indicate a specific failure of the sensor | |||||||||||||||||

problems |

| such | as water in | the | electronics | enclosure, | |||||||||||

| but indicates that the sensor is not correctly connected to | ||||||||||||||||

wiring damage or corrosion. |

|

|

|

|

|

| |||||||||||

|

|

|

|

|

| the electronics. If this message appears check that the | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||||

Use Figure | sensor harness is correctly installed to the connector on | ||||||||||||||||

procedures. |

|

|

|

|

|

|

|

| the bottom electronics board. |

|

|

| |||||

7.8.3.1 SIGNAL ADJUSTMENT |

|

|

|

|

| The gas sensor which is located inside the sensor | |||||||||||

|

|

|

|

| assembly housing can be replaced without replacement of | ||||||||||||

It is unlikely that any electrical adjustment will be | the housing. To replace the sensor: |

|

|

| |||||||||||||

required except when a new sensor is installed. |

|

|

|

|

|

|

|

|

| ||||||||

SERVICE

Page: 76