DESCRIPTION

This Pedestal Sump Pump is designed for home sumps. Unit is equipped with a 3-prong grounding- type power cord. Sleeve bearings on motor shaft never need lubrication. Automatic reset thermal protection. NOTICE: This unit is not designed for applications involving salt water or brine! Use with salt water or brine will void warranty.

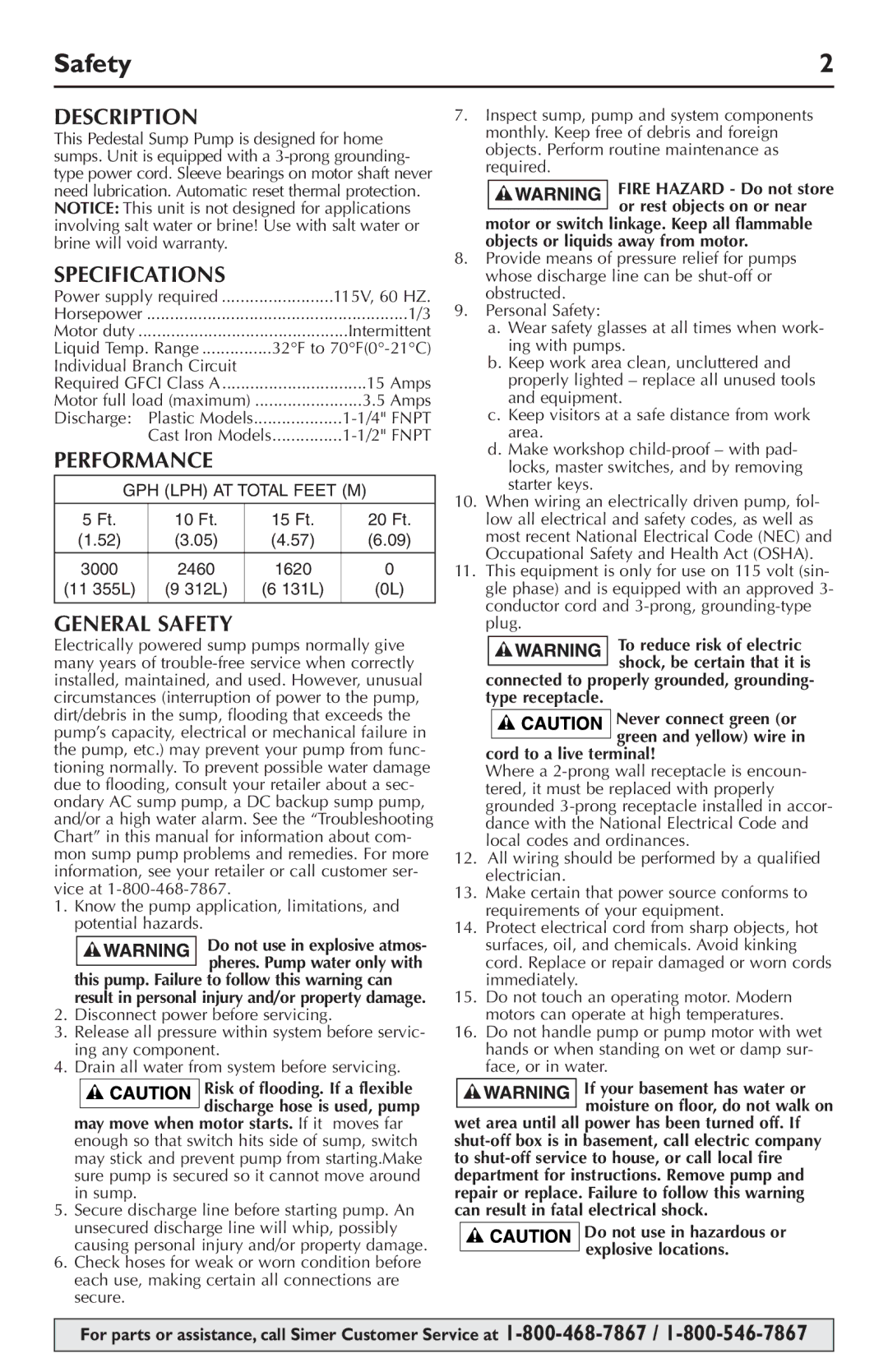

SPECIFICATIONS

Power supply required | 115V, 60 HZ. |

Horsepower | | | | 1/3 |

Motor duty | | | | | Intermittent |

Liquid Temp. Range | 32°F to 70°F(0°-21°C) |

Individual Branch Circuit | | | |

Required GFCI Class A | | 15 Amps |

Motor full load (maximum) | ....................... | 3.5 Amps |

Discharge: | Plastic Models | ................... | 1-1/4" FNPT |

| Cast Iron Models | 1-1/2" FNPT |

PERFORMANCE | | | |

GPH (LPH) AT TOTAL FEET (M) |

| | | | | |

5 Ft. | 10 Ft. | | 15 Ft. | | 20 Ft. |

(1.52) | (3.05) | | (4.57) | | (6.09) |

3000 | 2460 | | 1620 | | 0 |

(11 355L) | (9 312L) | | (6 131L) | | (0L) |

| | | | | |

GENERAL SAFETY

Electrically powered sump pumps normally give many years of trouble-free service when correctly installed, maintained, and used. However, unusual circumstances (interruption of power to the pump, dirt/debris in the sump, flooding that exceeds the pump’s capacity, electrical or mechanical failure in the pump, etc.) may prevent your pump from func- tioning normally. To prevent possible water damage due to flooding, consult your retailer about a sec- ondary AC sump pump, a DC backup sump pump, and/or a high water alarm. See the “Troubleshooting Chart” in this manual for information about com- mon sump pump problems and remedies. For more information, see your retailer or call customer ser- vice at 1-800-468-7867.

1.Know the pump application, limitations, and potential hazards.

Do not use in explosive atmos- pheres. Pump water only with

this pump. Failure to follow this warning can result in personal injury and/or property damage.

2.Disconnect power before servicing.

3.Release all pressure within system before servic- ing any component.

4.Drain all water from system before servicing.

Risk of flooding. If a flexible discharge hose is used, pump

may move when motor starts. If it moves far enough so that switch hits side of sump, switch may stick and prevent pump from starting.Make sure pump is secured so it cannot move around in sump.

5.Secure discharge line before starting pump. An unsecured discharge line will whip, possibly causing personal injury and/or property damage.

6.Check hoses for weak or worn condition before each use, making certain all connections are secure.

7.Inspect sump, pump and system components monthly. Keep free of debris and foreign objects. Perform routine maintenance as required.

FIRE HAZARD - Do not store or rest objects on or near

motor or switch linkage. Keep all flammable objects or liquids away from motor.

8.Provide means of pressure relief for pumps whose discharge line can be shut-off or obstructed.

9.Personal Safety:

a.Wear safety glasses at all times when work- ing with pumps.

b.Keep work area clean, uncluttered and properly lighted – replace all unused tools and equipment.

c.Keep visitors at a safe distance from work area.

d.Make workshop child-proof – with pad- locks, master switches, and by removing starter keys.

10.When wiring an electrically driven pump, fol- low all electrical and safety codes, as well as most recent National Electrical Code (NEC) and Occupational Safety and Health Act (OSHA).

11.This equipment is only for use on 115 volt (sin- gle phase) and is equipped with an approved 3- conductor cord and 3-prong, grounding-type plug.

To reduce risk of electric shock, be certain that it is

connected to properly grounded, grounding- type receptacle.

Never connect green (or green and yellow) wire in

Never connect green (or green and yellow) wire in

cord to a live terminal!

Where a 2-prong wall receptacle is encoun- tered, it must be replaced with properly grounded 3-prong receptacle installed in accor- dance with the National Electrical Code and local codes and ordinances.

12.All wiring should be performed by a qualified electrician.

13.Make certain that power source conforms to requirements of your equipment.

14.Protect electrical cord from sharp objects, hot surfaces, oil, and chemicals. Avoid kinking cord. Replace or repair damaged or worn cords immediately.

15.Do not touch an operating motor. Modern motors can operate at high temperatures.

16.Do not handle pump or pump motor with wet hands or when standing on wet or damp sur- face, or in water.

If your basement has water or moisture on floor, do not walk on

If your basement has water or moisture on floor, do not walk on

wet area until all power has been turned off. If shut-off box is in basement, call electric company to shut-off service to house, or call local fire department for instructions. Remove pump and repair or replace. Failure to follow this warning can result in fatal electrical shock.

Do not use in hazardous or explosive locations.

Do not use in hazardous or explosive locations.