5023SS, 5020B specifications

Simer Pumps is renowned for its commitment to innovative pump technology, and the Simer Pumps 5020B and 5023SS models exemplify this dedication. These pumps are designed to meet a variety of water movement needs, making them ideal for residential, agricultural, and light industrial applications.The Simer 5020B is a durable thermoplastic pump well-regarded for its versatility. It features a robust motor that operates effectively with a flow rate of up to 1200 gallons per hour. This pump is engineered for continuous operation, making it perfect for draining flooded areas, removing water from basements, or even managing irrigation systems. The 5020B is also equipped with an automatic float switch that activates the pump when water levels rise, ensuring effective water management without the need for manual intervention.

On the other hand, the Simer 5023SS offers superior performance with a stainless-steel construction, adding to its durability and resistance to corrosion. It comes with a powerful motor capable of moving up to 3000 gallons of water per hour, making it suitable for more demanding applications, such as large-scale irrigation or dewatering construction sites. The 5023SS is equipped with a thermal overload protection system, which prevents overheating and prolongs the lifespan of the pump.

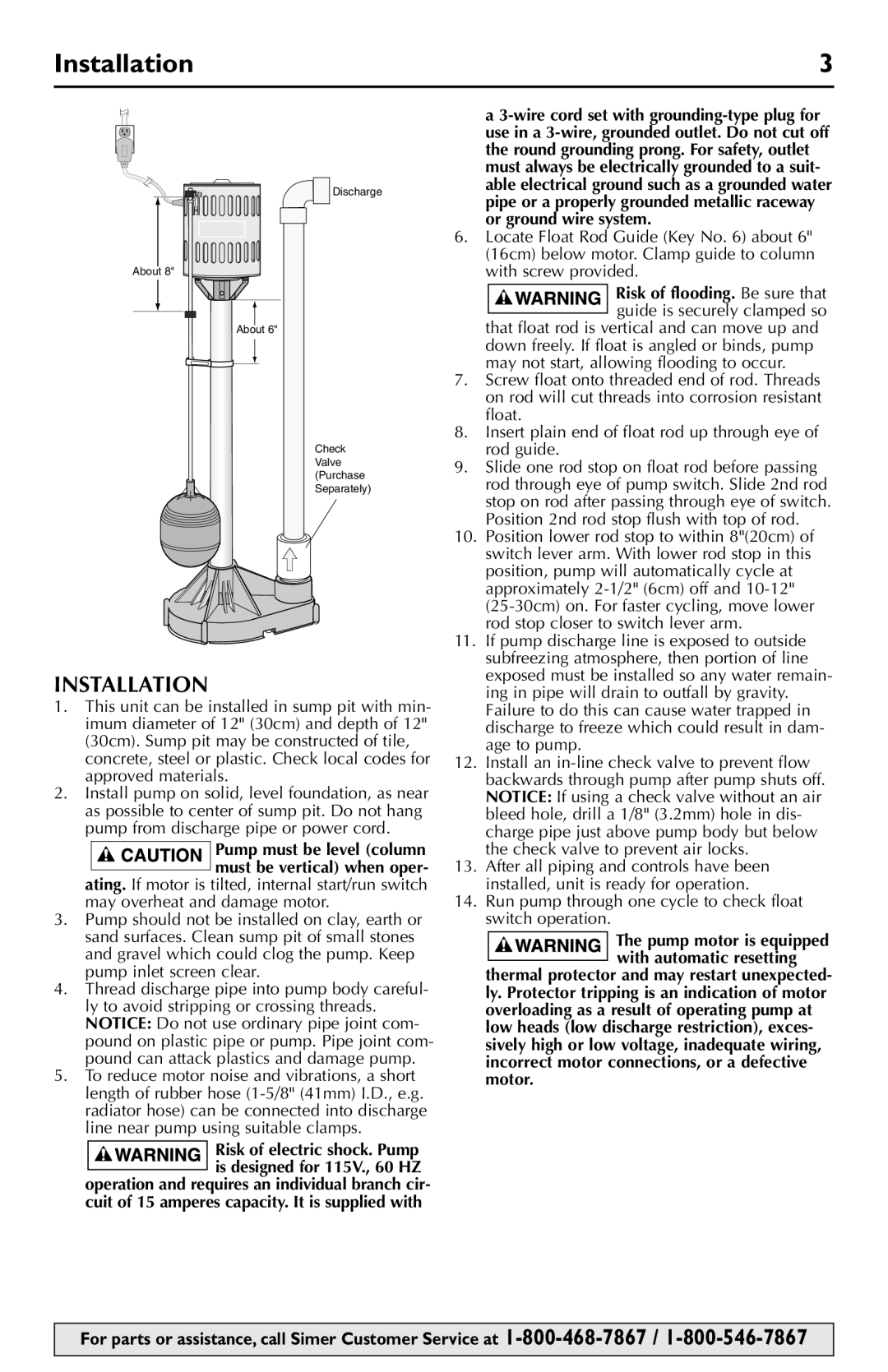

Both models are designed with user-friendliness in mind. They provide easy installation options and require minimal maintenance, making them ideal choices for both homeowners and professionals. The ergonomic design ensures that these pumps can be easily transported and placed wherever needed.

In terms of energy efficiency, both the 5020B and 5023SS have been engineered to minimize power consumption while maximizing performance. This makes them not only cost-effective choices but also environmentally friendly.

Overall, the Simer Pumps 5020B and 5023SS stand out for their reliable performance, innovative technology, and ease of use. These pumps are suitable for a variety of applications and are designed to deliver dependable water management solutions for many years. Whether you are looking for a pump for routine home use or for heavier industrial tasks, Simer Pumps delivers robust options that meet diverse needs effectively.