Basic Saw Operations

Workpiece Support

!Long workpieces have a tendency to tip WARNING over unless clamped down and properly

supported from underneath.

Clamps

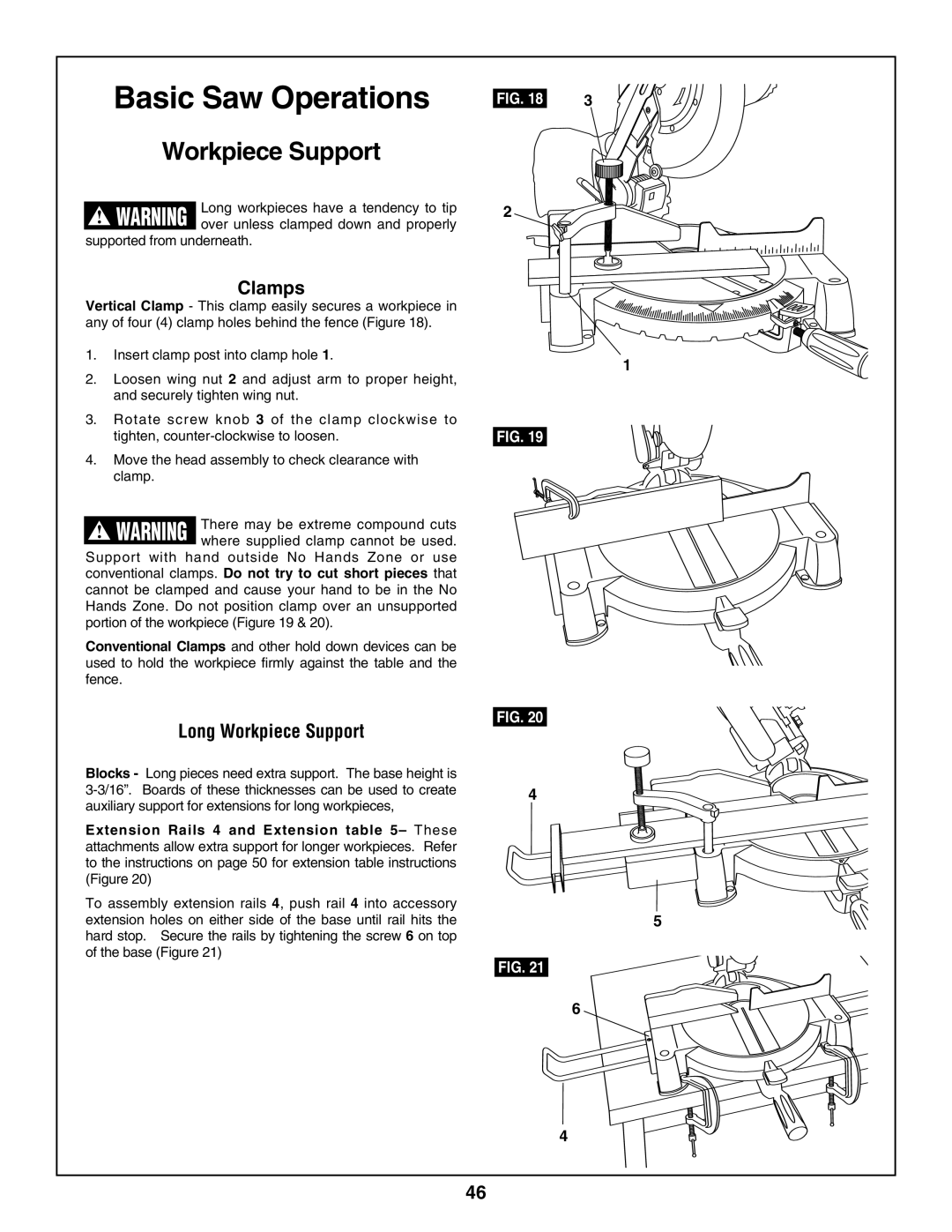

Vertical Clamp - This clamp easily secures a workpiece in any of four (4) clamp holes behind the fence (Figure 18).

1.Insert clamp post into clamp hole 1.

2.Loosen wing nut 2 and adjust arm to proper height, and securely tighten wing nut.

3.Rotate screw knob 3 of the clamp clockwise to tighten,

4.Move the head assembly to check clearance with clamp.

!WARNING There may be extreme compound cuts where supplied clamp cannot be used.

Support with hand outside No Hands Zone or use conventional clamps. Do not try to cut short pieces that cannot be clamped and cause your hand to be in the No Hands Zone. Do not position clamp over an unsupported portion of the workpiece (Figure 19 & 20).

Conventional Clamps and other hold down devices can be used to hold the workpiece firmly against the table and the fence.

Long Workpiece Support

Blocks - Long pieces need extra support. The base height is

Extension Rails 4 and Extension table 5– These attachments allow extra support for longer workpieces. Refer to the instructions on page 50 for extension table instructions (Figure 20)

To assembly extension rails 4, push rail 4 into accessory extension holes on either side of the base until rail hits the hard stop. Secure the rails by tightening the screw 6 on top of the base (Figure 21)

FIG. 18 | 3 |

2

1

FIG. 19

FIG. 20

4

5

FIG. 21

6

4

46