4 | Sentry |

WARNING

LIQUEFIED PETROLEUM (L.P.) PROPANE

GAS-FIRED BOILER LOCATION

REQUIRES SPECIAL ATTENTION Liquefied Petroleum (L.P.) propane gas is heavier than air. Therefore, propane boilers, piping, valves should not be installed in locations where propane leaking from defective equipment and piping will “pool” in a basement or other space below the leak.

A spark or flame from the boiler or other source may ignite the accumulated propane gas causing an explosion or fire. Provide a level, solid foundation for the boiler. Location should be as near the chimney as possible so that the flue pipe from boiler to chimney is short and direct.

The UNIFORM MECHANICAL CODE may be in effect in your geographic area

The following precautions are cited by the 1994 UNIFORM MECHANICAL CODE, section 304.6:

“LPG Appliances. Liquefied petroleum

Consult Chapter 5 of the 1994 UNIFORM MECHANICAL CODE for design criteria of the “approved” means for removal of unburned gas.

CHIMNEY REQUIREMENTS

A. Sentry boilers may be vented into a masonry vitreous tile- lined chimney or type “B” venting system NOT EXPOSED to the OUTDOORS below the roof line.

Venting and sizing of venting system must be in accordance with Part 7, Part 10 and Appendix G of the National Fuel Gas Code ANSI Z223.1, NFPA 54,

If a masonry chimney is exposed to the outdoors on one or more sides below the roof line (exterior chimney), ONE of the following options apply:

1.Chimney must be

2.If an exposed

a metallic liner, the boiler must first meet the require- ments of the following tables and paragraphs of the National Fuel Gas Code:

I.For Single Sentry Boiler - Paragraph 10.1.9 and table 10.11.

II.For multiple appliances - Paragraph 10.2.18 and table 10.12 (or 10.13 if applicable).

In addition, all requirements of Part 7, Part 10 and Appendix G of the National Fuel Gas Code and/or local codes apply.

B. If an existing boiler is removed from a common venting system, the common venting system may be too large

for proper venting of the remaining appliances connected to the common vent. Follow the test procedure shown in Appendix “A” on page 19 of this manual to insure proper operation of venting system and appliances.

C. Inspect for proper and tight construction. Any restrictions or obstructions must be removed. An existing chimney may require cleaning.

D. Chimney or vent must extend at least 3 feet above any ridge within 10 feet of the chimney.

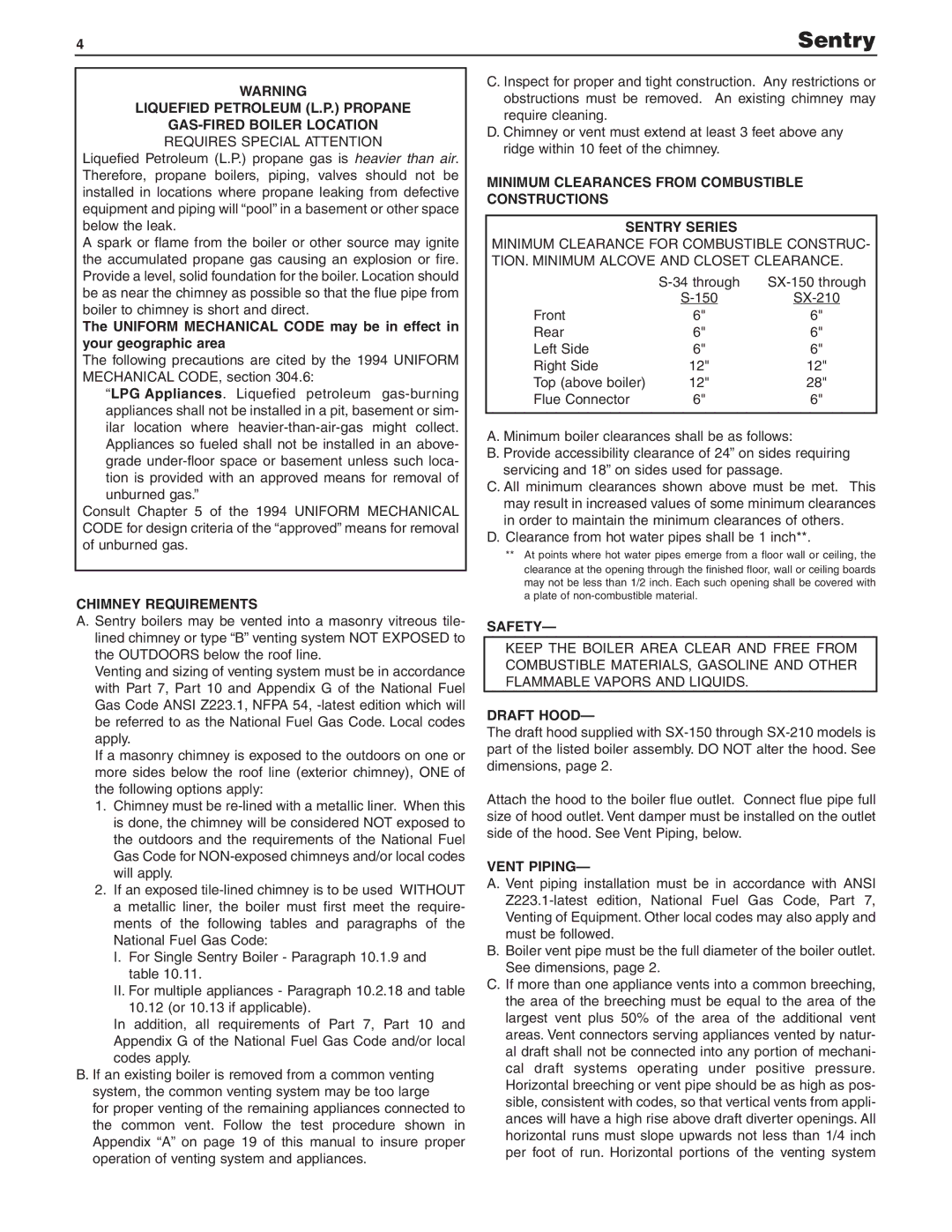

MINIMUM CLEARANCES FROM COMBUSTIBLE CONSTRUCTIONS

SENTRY SERIES

MINIMUM CLEARANCE FOR COMBUSTIBLE CONSTRUC- TION. MINIMUM ALCOVE AND CLOSET CLEARANCE.

| ||

| ||

Front | 6" | 6" |

Rear | 6" | 6" |

Left Side | 6" | 6" |

Right Side | 12" | 12" |

Top (above boiler) | 12" | 28" |

Flue Connector | 6" | 6" |

A. Minimum boiler clearances shall be as follows:

B. Provide accessibility clearance of 24” on sides requiring servicing and 18” on sides used for passage.

C. All minimum clearances shown above must be met. This may result in increased values of some minimum clearances in order to maintain the minimum clearances of others.

D.Clearance from hot water pipes shall be 1 inch**.

**At points where hot water pipes emerge from a floor wall or ceiling, the clearance at the opening through the finished floor, wall or ceiling boards may not be less than 1/2 inch. Each such opening shall be covered with a plate of

SAFETY—

KEEP THE BOILER AREA CLEAR AND FREE FROM COMBUSTIBLE MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS.

DRAFT HOOD—

The draft hood supplied with

Attach the hood to the boiler flue outlet. Connect flue pipe full size of hood outlet. Vent damper must be installed on the outlet side of the hood. See Vent Piping, below.

VENT PIPING—

A. Vent piping installation must be in accordance with ANSI

B.Boiler vent pipe must be the full diameter of the boiler outlet. See dimensions, page 2.

C.If more than one appliance vents into a common breeching, the area of the breeching must be equal to the area of the largest vent plus 50% of the area of the additional vent areas. Vent connectors serving appliances vented by natur- al draft shall not be connected into any portion of mechani- cal draft systems operating under positive pressure. Horizontal breeching or vent pipe should be as high as pos- sible, consistent with codes, so that vertical vents from appli- ances will have a high rise above draft diverter openings. All horizontal runs must slope upwards not less than 1/4 inch per foot of run. Horizontal portions of the venting system