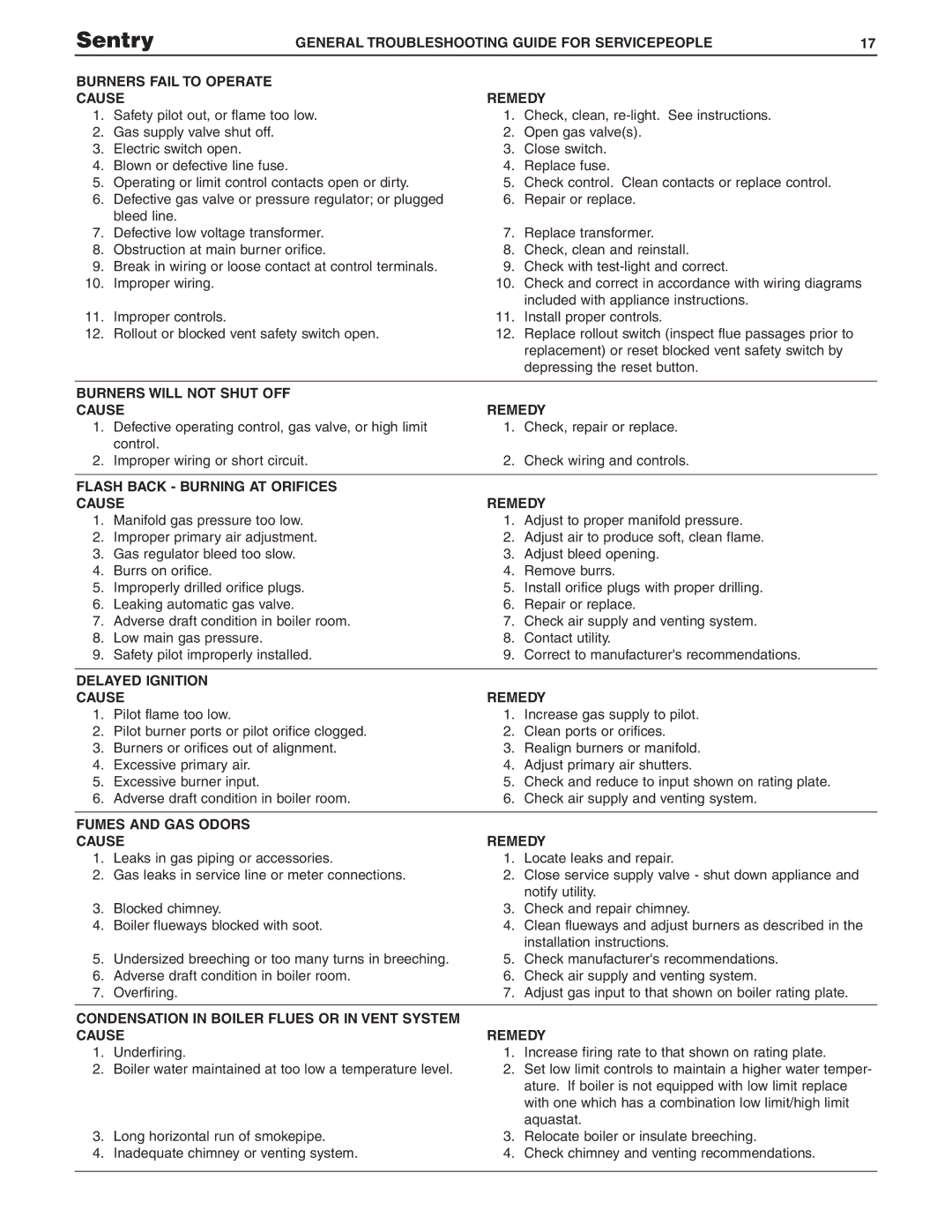

Sentry | GENERAL TROUBLESHOOTING GUIDE FOR SERVICEPEOPLE | 17 | |||

BURNERS FAIL TO OPERATE |

|

|

|

| |

CAUSE |

| REMEDY |

| ||

1. | Safety pilot out, or flame too low. | 1. | Check, clean, |

| |

2. | Gas supply valve shut off. |

| 2. | Open gas valve(s). |

|

3. | Electric switch open. |

| 3. | Close switch. |

|

4. | Blown or defective line fuse. |

| 4. | Replace fuse. |

|

5. | Operating or limit control contacts open or dirty. | 5. | Check control. Clean contacts or replace control. |

| |

6. | Defective gas valve or pressure regulator; or plugged | 6. | Repair or replace. |

| |

| bleed line. |

|

|

|

|

7. | Defective low voltage transformer. | 7. | Replace transformer. |

| |

8. | Obstruction at main burner orifice. | 8. | Check, clean and reinstall. |

| |

9. | Break in wiring or loose contact at control terminals. | 9. | Check with |

| |

10. | Improper wiring. |

| 10. | Check and correct in accordance with wiring diagrams | |

|

|

|

| included with appliance instructions. |

|

11. | Improper controls. |

| 11. | Install proper controls. |

|

12. | Rollout or blocked vent safety switch open. | 12. | Replace rollout switch (inspect flue passages prior to |

| |

|

|

|

| replacement) or reset blocked vent safety switch by |

|

|

|

|

| depressing the reset button. |

|

|

|

|

|

| |

BURNERS WILL NOT SHUT OFF |

|

|

|

| |

CAUSE |

| REMEDY |

| ||

1. | Defective operating control, gas valve, or high limit | 1. | Check, repair or replace. |

| |

| control. |

|

|

|

|

2. | Improper wiring or short circuit. | 2. | Check wiring and controls. |

| |

|

|

|

| ||

FLASH BACK - BURNING AT ORIFICES |

|

|

| ||

CAUSE |

| REMEDY |

| ||

1. | Manifold gas pressure too low. | 1. | Adjust to proper manifold pressure. |

| |

2. | Improper primary air adjustment. | 2. | Adjust air to produce soft, clean flame. |

| |

3. | Gas regulator bleed too slow. | 3. | Adjust bleed opening. |

| |

4. | Burrs on orifice. |

| 4. | Remove burrs. |

|

5. | Improperly drilled orifice plugs. | 5. | Install orifice plugs with proper drilling. |

| |

6. | Leaking automatic gas valve. |

| 6. | Repair or replace. |

|

7. | Adverse draft condition in boiler room. | 7. | Check air supply and venting system. |

| |

8. | Low main gas pressure. |

| 8. | Contact utility. |

|

9. | Safety pilot improperly installed. | 9. | Correct to manufacturer's recommendations. |

| |

|

|

|

|

| |

DELAYED IGNITION |

|

|

|

| |

CAUSE |

| REMEDY |

| ||

1. | Pilot flame too low. |

| 1. | Increase gas supply to pilot. |

|

2. | Pilot burner ports or pilot orifice clogged. | 2. | Clean ports or orifices. |

| |

3. | Burners or orifices out of alignment. | 3. | Realign burners or manifold. |

| |

4. | Excessive primary air. |

| 4. | Adjust primary air shutters. |

|

5. | Excessive burner input. |

| 5. | Check and reduce to input shown on rating plate. |

|

6. | Adverse draft condition in boiler room. | 6. | Check air supply and venting system. |

| |

|

|

|

|

| |

FUMES AND GAS ODORS |

|

|

|

| |

CAUSE |

| REMEDY |

| ||

1. | Leaks in gas piping or accessories. | 1. | Locate leaks and repair. |

| |

2. | Gas leaks in service line or meter connections. | 2. | Close service supply valve - shut down appliance and |

| |

|

|

|

| notify utility. |

|

3. | Blocked chimney. |

| 3. | Check and repair chimney. |

|

4. | Boiler flueways blocked with soot. | 4. | Clean flueways and adjust burners as described in the | ||

|

|

|

| installation instructions. |

|

5. | Undersized breeching or too many turns in breeching. | 5. | Check manufacturer's recommendations. |

| |

6. | Adverse draft condition in boiler room. | 6. | Check air supply and venting system. |

| |

7. | Overfiring. |

| 7. | Adjust gas input to that shown on boiler rating plate. |

|

|

|

|

| ||

CONDENSATION IN BOILER FLUES OR IN VENT SYSTEM |

|

|

| ||

CAUSE |

| REMEDY |

| ||

1. | Underfiring. |

| 1. | Increase firing rate to that shown on rating plate. |

|

2. | Boiler water maintained at too low a temperature level. | 2. | Set low limit controls to maintain a higher water temper- | ||

|

|

|

| ature. If boiler is not equipped with low limit replace |

|

|

|

|

| with one which has a combination low limit/high limit |

|

|

|

|

| aquastat. |

|

3. | Long horizontal run of smokepipe. | 3. | Relocate boiler or insulate breeching. |

| |

4. | Inadequate chimney or venting system. | 4. | Check chimney and venting recommendations. |

| |

|

|

|

|

|

|

Page 17

Image 17