Sentry | 7 |

B. 1. This device must be installed after the boiler draft hood (between the draft hood outlet and the connector to the out- door chimney or vent) as close to the draft hood as practi- cable, and without modification of the draft hood or the vent damper. (See figures 1, 2 and 3.)

2.The inlet size of the vent damper must be the same nomi- nal trade size as the outlet of the draft hood.

3.This device must be located in a venting system or section of a venting system so that it serves only the single appli- ance for which it is installed. (See figure 4.)

4.Clearances of not less than 6 inches (152MM) must be maintained from combustible materials, with provisions for service access.

C.NOW, PROCEED AS FOLLOWS:

Remove the cover from the aquastat control. Note the Molex connector (MALE PLUG) inside the control box (see figure 6). Remove knockout in the control housing marked for vent damper, pass “Receptacle B” of vent damper harness through the knockout and attach the flexible metallic connector to the control housing with the nut. Join the two halves of the Molex connector (MALE PLUG AND RECEPTACLE B). Replace the control cover. Attach the other side of vent damper harness to vent damper operator (if not attached) and connect Molex con- nector to operator receptacle. (See figures 1 and 2.)

D.AFTER INSTALLATION:

1.Operate system through two complete cycles to check for opening and closing in proper sequence, and proper burn- er operation. DAMPER MUST BE IN OPEN POSITION WHEN BOILER MAIN BURNERS ARE OPERATING.

2.Perform installation checks as required by ANSI specifica- tion Z21.66. (See Vent Damper Instructions.)

3.Check the troubleshooting section if problems arise with the installation.

E.THERMOSTAT HEAT ANTICIPATOR ADJUSTMENTS

If the 24V room thermostat that controls this boiler has an adjustable heat anticipator and has previously been adjusted without a vent damper, then see publication

GAS PIPING—

A.Local installation codes apply. The pipe joint compound used on threads must be resistant to the action of liquefied petro- leum gases.

B.The gas supply line to the boiler should be run directly from the meter for natural gas or from the fuel tank for L.P. propane gas. See page 2 for location of union and manual main shutoff valve that may be specified locally.

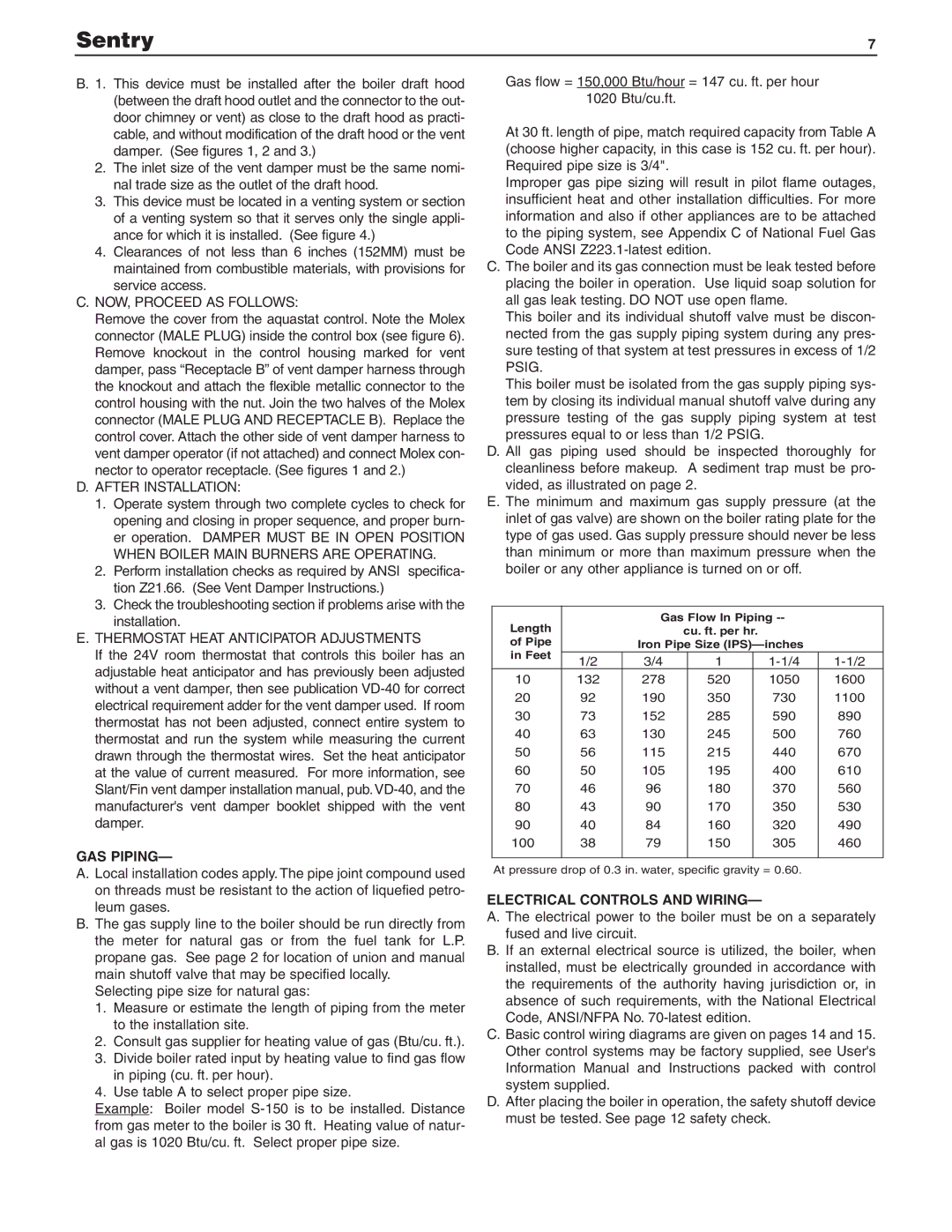

Selecting pipe size for natural gas:

1.Measure or estimate the length of piping from the meter to the installation site.

2.Consult gas supplier for heating value of gas (Btu/cu. ft.).

3.Divide boiler rated input by heating value to find gas flow in piping (cu. ft. per hour).

4.Use table A to select proper pipe size.

Example: Boiler model

Gas flow = 150,000 Btu/hour = 147 cu. ft. per hour 1020 Btu/cu.ft.

At 30 ft. length of pipe, match required capacity from Table A (choose higher capacity, in this case is 152 cu. ft. per hour). Required pipe size is 3/4".

Improper gas pipe sizing will result in pilot flame outages, insufficient heat and other installation difficulties. For more information and also if other appliances are to be attached to the piping system, see Appendix C of National Fuel Gas Code ANSI

C.The boiler and its gas connection must be leak tested before placing the boiler in operation. Use liquid soap solution for all gas leak testing. DO NOT use open flame.

This boiler and its individual shutoff valve must be discon- nected from the gas supply piping system during any pres- sure testing of that system at test pressures in excess of 1/2 PSIG.

This boiler must be isolated from the gas supply piping sys- tem by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 PSIG.

D.All gas piping used should be inspected thoroughly for cleanliness before makeup. A sediment trap must be pro- vided, as illustrated on page 2.

E.The minimum and maximum gas supply pressure (at the inlet of gas valve) are shown on the boiler rating plate for the type of gas used. Gas supply pressure should never be less than minimum or more than maximum pressure when the boiler or any other appliance is turned on or off.

Length |

| Gas Flow In Piping |

| ||||

|

| cu. ft. per hr. |

|

| |||

of Pipe |

| Iron Pipe Size |

| ||||

in Feet | 1/2 | 3/4 |

| 1 |

| ||

|

|

| |||||

10 | 132 | 278 |

| 520 |

| 1050 | 1600 |

20 | 92 | 190 |

| 350 |

| 730 | 1100 |

30 | 73 | 152 |

| 285 |

| 590 | 890 |

40 | 63 | 130 |

| 245 |

| 500 | 760 |

50 | 56 | 115 |

| 215 |

| 440 | 670 |

60 | 50 | 105 |

| 195 |

| 400 | 610 |

70 | 46 | 96 |

| 180 |

| 370 | 560 |

80 | 43 | 90 |

| 170 |

| 350 | 530 |

90 | 40 | 84 |

| 160 |

| 320 | 490 |

100 | 38 | 79 |

| 150 |

| 305 | 460 |

|

|

|

|

|

|

|

|

At pressure drop of 0.3 in. water, specific gravity = 0.60.

ELECTRICAL CONTROLS AND WIRING—

A. The electrical power to the boiler must be on a separately fused and live circuit.

B. If an external electrical source is utilized, the boiler, when installed, must be electrically grounded in accordance with the requirements of the authority having jurisdiction or, in absence of such requirements, with the National Electrical Code, ANSI/NFPA No.

C.Basic control wiring diagrams are given on pages 14 and 15. Other control systems may be factory supplied, see User's Information Manual and Instructions packed with control system supplied.

D.After placing the boiler in operation, the safety shutoff device must be tested. See page 12 safety check.