Page 10 | GB100W NATURAL OR PROPANE BOILER |

| INSTALLATION AND OPERATING INSTRUCTIONS |

CAUTION: To prevent damage due to excessive condensation, one of the following piping options should be used.

System Bypass

For systems using a circulator on the return as either a single zone, or multiple zones with zone valves, install a system bypass line between the supply and return on the suction side of the circulator, see Figure 7. Install a metering valve in this bypass line to regulate the amount of flow that will be diverted to the return. A plug valve offers the best control for this application. Although other valves may be less expensive, a plug valve will be easier to set accurately.

In the absence of a flow indicator, set the metering valve using temperature as a guide. The accompanying diagram suggests one scenario. This addition requires only two tees, a plug valve, and a small amount of pipe and offers the simplest approach to reliably control condensation. For this system and those that follow, be aware that you are using a percentage of the pump capacity to blend, but the friction loss for the entire pump flow has been reduced. In most cases, the standard pump packaged with the boiler has enough capacity to feed the baseboard distribution system and the bypass line.

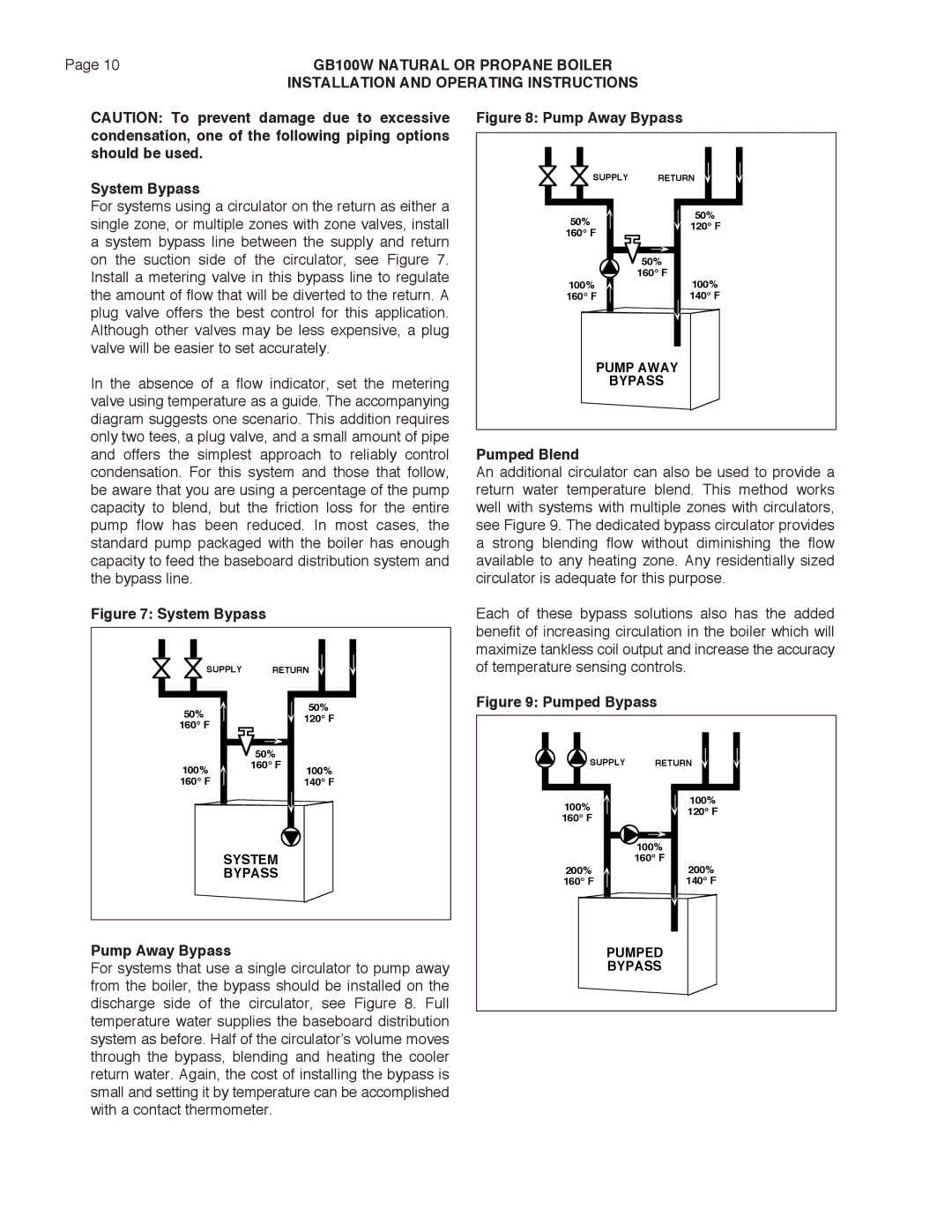

Figure 8: Pump Away Bypass

SUPPLY | RETURN | |

50% | 50% | |

120° F | ||

160° F | ||

| ||

| 50% | |

| 160° F | |

100% | 100% | |

160° F | 140° F |

PUMP AWAY

BYPASS

Pumped Blend

An additional circulator can also be used to provide a return water temperature blend. This method works well with systems with multiple zones with circulators, see Figure 9. The dedicated bypass circulator provides a strong blending flow without diminishing the flow available to any heating zone. Any residentially sized circulator is adequate for this purpose.

Figure 7: System Bypass

SUPPLY | RETURN | |

50% |

| 50% |

| 120° F | |

160° F |

| |

|

| |

| 50% |

|

100% | 160° F | 100% |

| ||

160° F |

| 140° F |

SYSTEM

BYPASS

Pump Away Bypass

For systems that use a single circulator to pump away from the boiler, the bypass should be installed on the discharge side of the circulator, see Figure 8. Full temperature water supplies the baseboard distribution system as before. Half of the circulator’s volume moves through the bypass, blending and heating the cooler return water. Again, the cost of installing the bypass is small and setting it by temperature can be accomplished with a contact thermometer.

Each of these bypass solutions also has the added benefit of increasing circulation in the boiler which will maximize tankless coil output and increase the accuracy of temperature sensing controls.

Figure 9: Pumped Bypass

SUPPLY | RETURN | |

100% | 100% | |

120° F | ||

160° F | ||

| ||

| 100% | |

| 160° F | |

200% | 200% | |

160° F | 140° F | |

PUMPED | ||

BYPASS | ||