Page 12 | GB100W NATURAL OR PROPANE BOILER |

| INSTALLATION AND OPERATING INSTRUCTIONS |

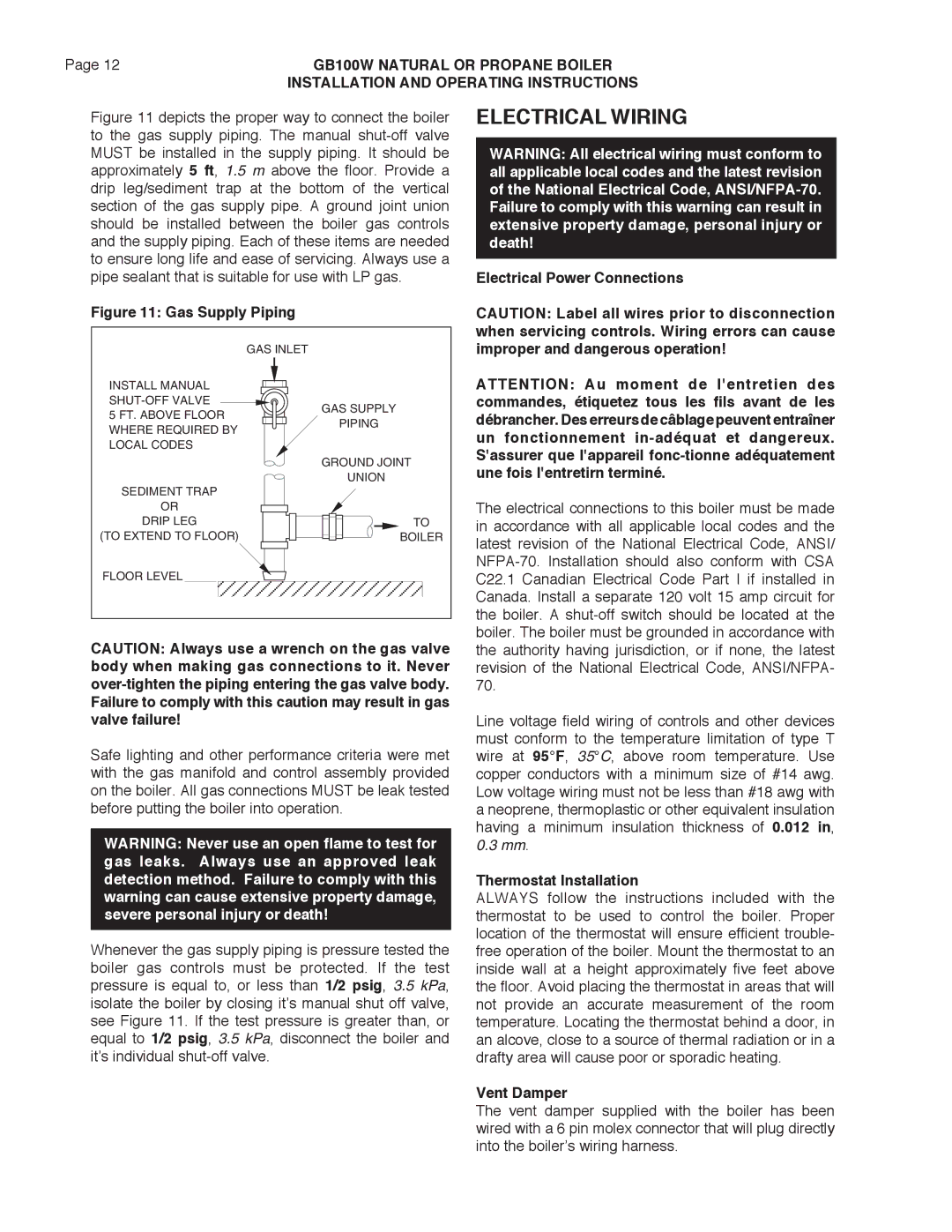

Figure 11 depicts the proper way to connect the boiler to the gas supply piping. The manual shut-off valve MUST be installed in the supply piping. It should be approximately 5 ft, 1.5 m above the floor. Provide a drip leg/sediment trap at the bottom of the vertical section of the gas supply pipe. A ground joint union should be installed between the boiler gas controls and the supply piping. Each of these items are needed to ensure long life and ease of servicing. Always use a pipe sealant that is suitable for use with LP gas.

Figure 11: Gas Supply Piping

GAS INLET

ELECTRICAL WIRING

WARNING: All electrical wiring must conform to all applicable local codes and the latest revision of the National Electrical Code,

Electrical Power Connections

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation!

INSTALL MANUAL ![]()

![]()

![]() 5 FT. ABOVE FLOOR

5 FT. ABOVE FLOOR

WHERE REQUIRED BY LOCAL CODES

SEDIMENT TRAP

OR

DRIP LEG

(TO EXTEND TO FLOOR)

GAS SUPPLY

PIPING

GROUND JOINT

UNION

TO

BOILER

ATTENTION: Au moment de l'entretien des commandes, étiquetez tous les fils avant de les débrancher. Des erreurs de câblage peuvent entraîner un fonctionnement

The electrical connections to this boiler must be made in accordance with all applicable local codes and the latest revision of the National Electrical Code, ANSI/

FLOOR LEVEL

CAUTION: Always use a wrench on the gas valve body when making gas connections to it. Never

Safe lighting and other performance criteria were met with the gas manifold and control assembly provided on the boiler. All gas connections MUST be leak tested before putting the boiler into operation.

WARNING: Never use an open flame to test for gas leaks. Always use an approved leak detection method. Failure to comply with this warning can cause extensive property damage, severe personal injury or death!

Whenever the gas supply piping is pressure tested the boiler gas controls must be protected. If the test pressure is equal to, or less than 1/2 psig, 3.5 kPa, isolate the boiler by closing it’s manual shut off valve, see Figure 11. If the test pressure is greater than, or equal to 1/2 psig, 3.5 kPa, disconnect the boiler and it’s individual

C22.1 Canadian Electrical Code Part I if installed in Canada. Install a separate 120 volt 15 amp circuit for the boiler. A

Line voltage field wiring of controls and other devices must conform to the temperature limitation of type T wire at 95°F, 35°C, above room temperature. Use copper conductors with a minimum size of #14 awg. Low voltage wiring must not be less than #18 awg with a neoprene, thermoplastic or other equivalent insulation having a minimum insulation thickness of 0.012 in, 0.3 mm.

Thermostat Installation

ALWAYS follow the instructions included with the thermostat to be used to control the boiler. Proper location of the thermostat will ensure efficient trouble- free operation of the boiler. Mount the thermostat to an inside wall at a height approximately five feet above the floor. Avoid placing the thermostat in areas that will not provide an accurate measurement of the room temperature. Locating the thermostat behind a door, in an alcove, close to a source of thermal radiation or in a drafty area will cause poor or sporadic heating.

Vent Damper

The vent damper supplied with the boiler has been wired with a 6 pin molex connector that will plug directly into the boiler’s wiring harness.