Page 8 | GB100W NATURAL OR PROPANE BOILER |

| INSTALLATION AND OPERATING INSTRUCTIONS |

Fasten the vent damper to the flue collar and vent pipe using at least 3 corrosion resistant sheet metal screws

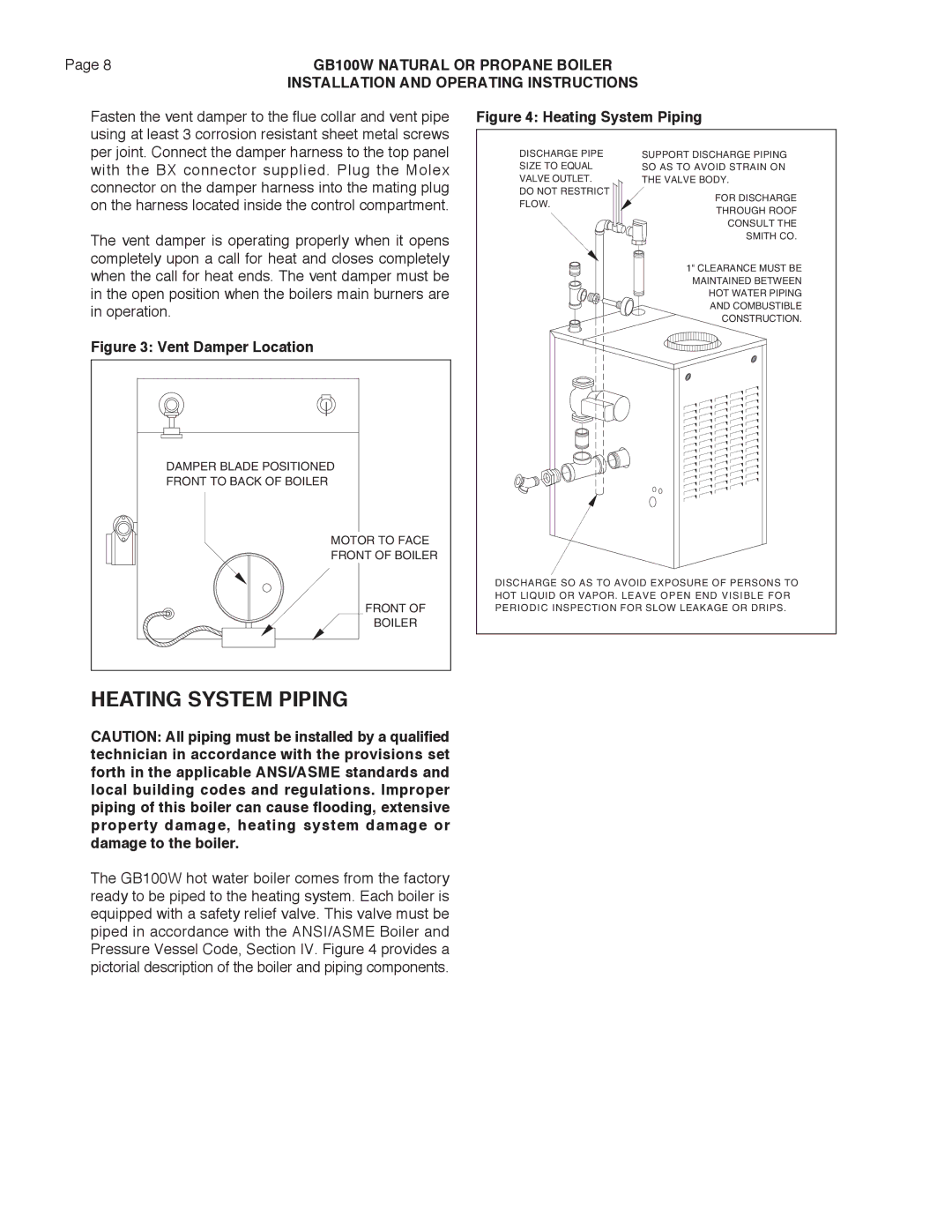

Figure 4: Heating System Piping

per joint. Connect the damper harness to the top panel with the BX connector supplied. Plug the Molex connector on the damper harness into the mating plug on the harness located inside the control compartment.

The vent damper is operating properly when it opens completely upon a call for heat and closes completely when the call for heat ends. The vent damper must be in the open position when the boilers main burners are in operation.

Figure 3: Vent Damper Location

DAMPER BLADE POSITIONED

FRONT TO BACK OF BOILER

MOTOR TO FACE

FRONT OF BOILER

DISCHARGE PIPE SIZE TO EQUAL VALVE OUTLET. DO NOT RESTRICT FLOW.

SUPPORT DISCHARGE PIPING SO AS TO AVOID STRAIN ON THE VALVE BODY.

FOR DISCHARGE

THROUGH ROOF

CONSULT THE

SMITH CO.

1" CLEARANCE MUST BE MAINTAINED BETWEEN HOT WATER PIPING AND COMBUSTIBLE CONSTRUCTION.

FRONT OF

BOILER

DISCHARGE SO AS TO AVOID EXPOSURE OF PERSONS TO HOT LIQUID OR VAPOR. LEAVE OPEN END VISIBLE FOR PERIODIC INSPECTION FOR SLOW LEAKAGE OR DRIPS.

HEATING SYSTEM PIPING

CAUTION: All piping must be installed by a qualified technician in accordance with the provisions set forth in the applicable ANSI/ASME standards and local building codes and regulations. Improper piping of this boiler can cause flooding, extensive property damage, heating system damage or damage to the boiler.

The GB100W hot water boiler comes from the factory ready to be piped to the heating system. Each boiler is equipped with a safety relief valve. This valve must be piped in accordance with the ANSI/ASME Boiler and Pressure Vessel Code, Section IV. Figure 4 provides a pictorial description of the boiler and piping components.