SECTION 4 - SERVICE

WARNING

Once blades are disengaged, they should come to a complete stop in 7 seconds or less. If the blades continue to rotate after 7 seconds, the electric clutch must be checked. Replacement of electric clutch may be necessary. Return machine to dealer for replacement. DO NOT CONTINUE to operate mower if blades fail to stop in 7 seconds.

4.1 ELECTRIC CLUTCH ADJUSTMENT

The Pro Hydro Mowers are equipped with an Electric Blade Control. The cutter blades should STOP within 7 seconds

after the BLADE SWITCH is moved to "OFF" position. If blade stopping time exceeds 7 seconds, check the dutch air gap setting as follows:

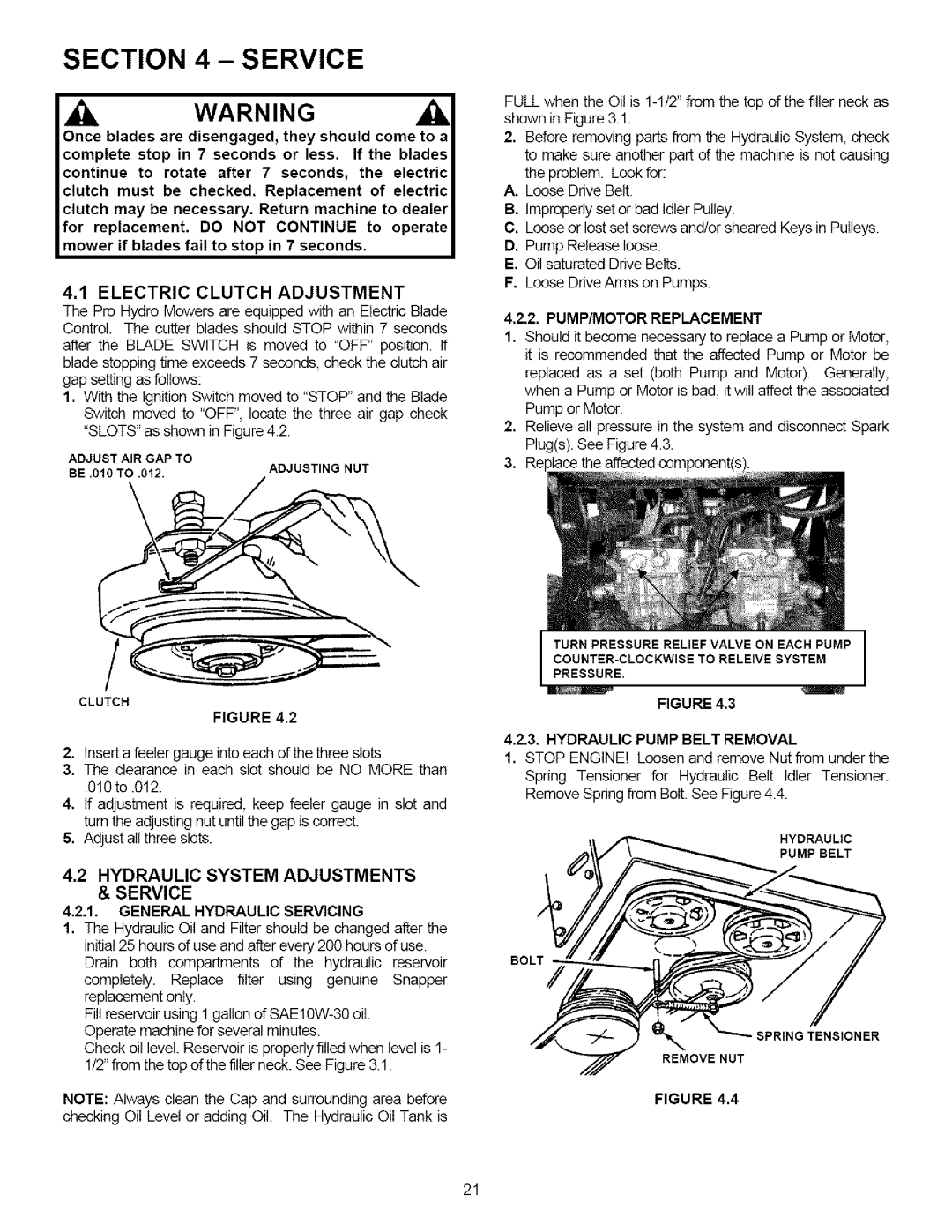

1.With the Ignition Switch moved to "STOP" and the Blade Switch moved to "OFF", locate the three air gap check "SLOTS" as shown in Figure 4.2.

ADJUST | AIR GAP TO | ADJUSTING NUT | |

BE .010 | TO .012. | ||

|

CLUTCH

FIGURE 4.2

2.Insert a feeler gauge into each of the three slots.

3.The clearance in each slot should be NO MORE than

.010 to .012.

4.If adjustment is required, keep feeler gauge in slot and turn the adjusting nut until the gap is correct.

5.Adjust allthree slots.

4,2 HYDRAULIC SYSTEM ADJUSTMENTS & SERVICE

4,2.1. GENERAL HYDRAULIC SERVICING

1.The Hydraulic Oil and Filter should be changed after the initial 25 hours of use and after every 200 hours of use. Drain both compartments of the hydraulic reservoir completely. Replace filter using genuine Snapper replacement only.

Fill reservoir using 1 gallon of

Check oil level. Reservoir is properly filled when level is 1- 1/2" from the top of the filler neck. See Figure 3.1.

NOTE: Always clean the Cap and surrounding area before checking OiI Level or adding Oil. The Hydraulic OiI Tank is

FULL when the Oil is

2.Before removing parts from the Hydraulic System, check to make sure another part of the machine is not causing

the problem. Look for:

A.Loose Drive Belt.

B.Improperly set or bad Idler Pulley.

C.Loose or lost set screws and/or sheared Keys in Pulleys.

D.Pump Release loose.

E.Oil saturated Drive Belts.

F.Loose Drive Arms on Pumps.

4,2,2, PUMP/MOTOR REPLACEMENT

1.Should it become necessary to replace a Pump or Motor, it is recommended that the affected Pump or Motor be replaced as a set (both Pump and Motor). Generally, when a Pump or Motor is bad, it wilI affect the associated Pump or Motor.

2.Relieve all pressure in the system and disconnect Spark

Plug(s). See Figure 4.3.

3.

TURN PRESSURE RELIEF VALVE ON EACH PUMP

PRESSURE.

FIGURE 4,3

4,2,3, HYDRAULIC PUMP BELT REMOVAL

1.STOP ENGINE! Loosen and remove Nut from under the

Spring Tensioner for Hydraulic Belt Idler Tensioner. Remove Spring from Bolt. See Figure 4.4.

HYDRAULIC

PUMP BELT

BOLT

/

SPRING TENSIONER

REMOVE NUT

FIGURE 4.4

21