Model SB1269 | O P E R A T I O N | For Product Mfg. Since 1/10 |

Operation

When the deadman clamp cap screws are loose, the deadman clamp slides along the lathe way, and the taper attachment is disengaged. Normal lathe turning operations can be conducted.

When the deadman clamp cap screws are tightened, the deadman clamp is locked to the lathe way, and the taper attachment is engaged. At this point tapered turning operations can be made.

To use the taper attachment:

1. DISCONNECT LATHE FROM POWER!

2. Move the carriage, cross slide, and compound rest so your turning bit is at your needed location to begin the tapered cut.

3. Using an 8mm hex wrench, tighten both deadman cap screws so the deadman clamps against the lathe bedway, as shown in Figure 23.

![]() Cap Screw

Cap Screw

Figure 23. Deadman clamp location.

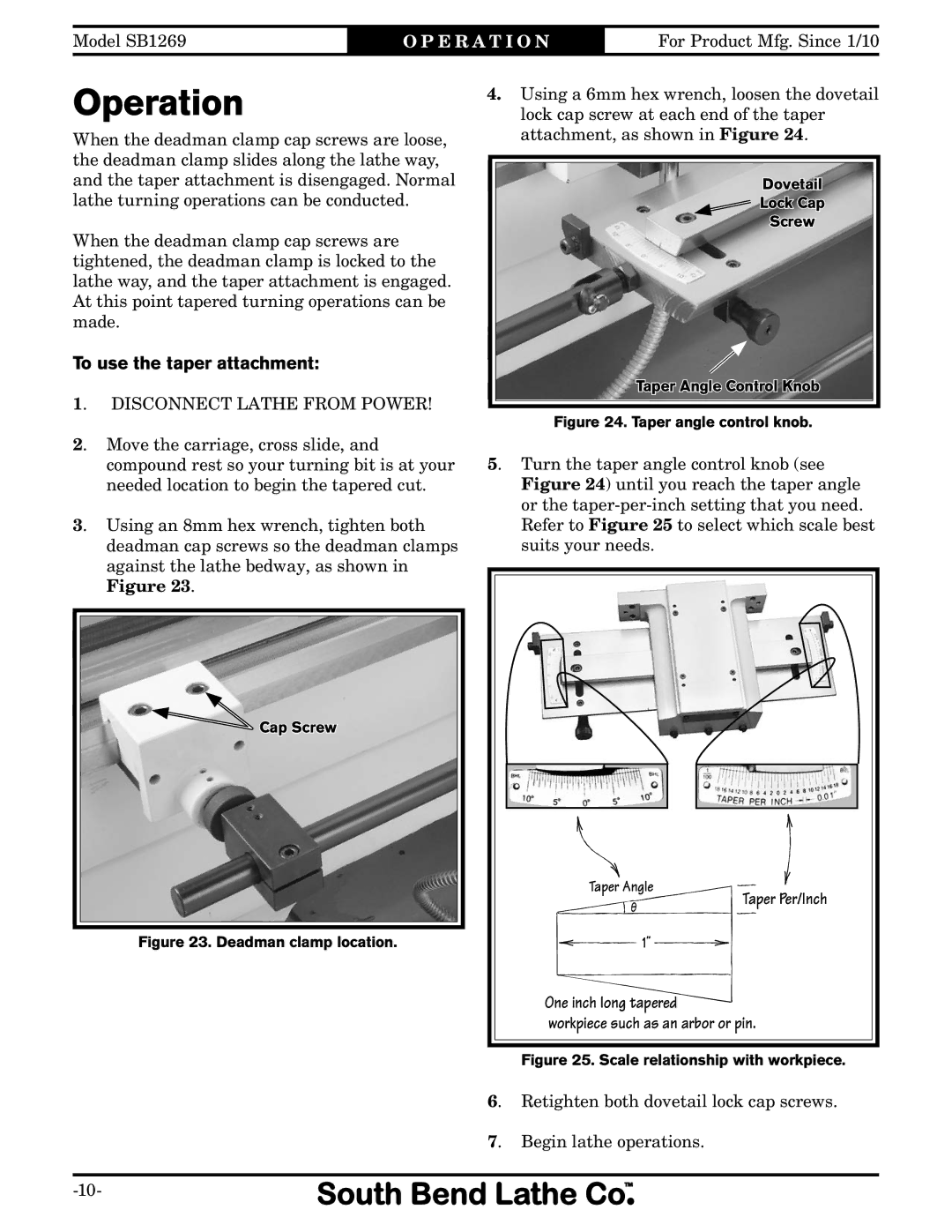

4.Using a 6mm hex wrench, loosen the dovetail lock cap screw at each end of the taper attachment, as shown in Figure 24.

Dovetail

Lock Cap

Screw

Taper Angle Control Knob

Figure 24.

Taper angle control knob.

Taper angle control knob.

5. Turn the taper angle control knob (see Figure 24) until you reach the taper angle or the

Taper Angle | Taper Per/Inch | ||

0 | |||

| |||

|

|

| |

1 |

| ||

One inch long tapered

workpiece such as an arbor or pin.

Figure 25. Scale relationship with workpiece.

6. Retighten both dovetail lock cap screws.

7. Begin lathe operations.