For Product Mfg. Since 1/10 | P R E P A R A T I O N | Model SB1269 |

17. Make sure the copper plug is still inside of the slide block.

18. With the help of an assistant, raise the taper attachment underneath the slide block, so the pivot pin slides into the pin bore in the slide block (see Figure 12).

19. With your assistant aligning the taper attachment mounting holes, use an 8mm hex wrench to tighten the four mounting cap screws and secure the taper attachment to the carriage face (see Figure 12).

Pin and Pin

Bore

Mounting

Cap Screw

Figure 12.

Taper attachment installation.

Taper attachment installation.

20. Using a 4mm hex wrench, snug the slide block set screw so the copper plug is slightly preloaded against the pivot pin (see Figure 13).

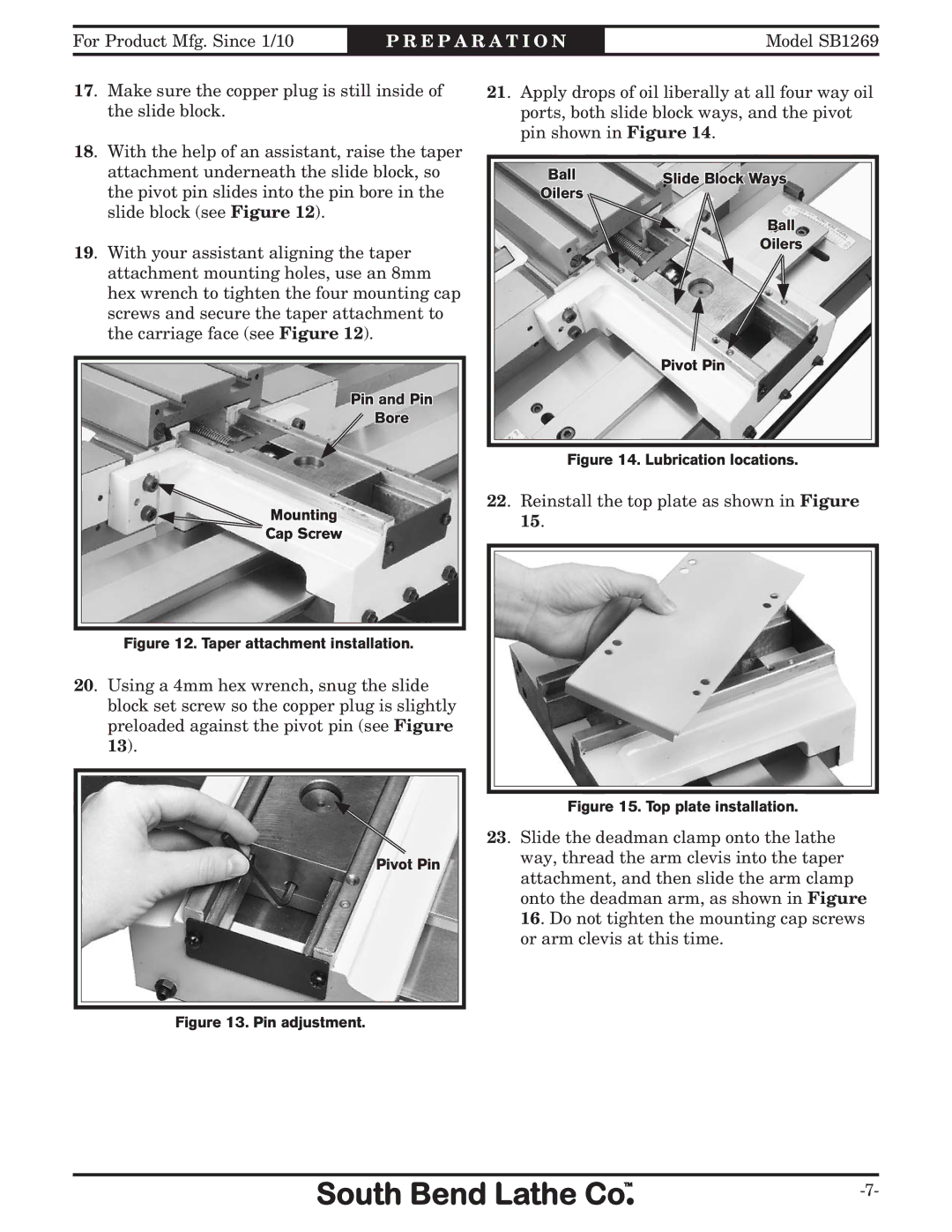

21. Apply drops of oil liberally at all four way oil ports, both slide block ways, and the pivot pin shown in Figure 14.

Ball | Slide Block Ways |

Oilers |

|

Ball

Oilers

Pivot Pin

Figure 14. Lubrication locations.

22. Reinstall the top plate as shown in Figure 15.

Pivot Pin

Figure 15.

Top plate installation.

Top plate installation.

23. Slide the deadman clamp onto the lathe way, thread the arm clevis into the taper attachment, and then slide the arm clamp onto the deadman arm, as shown in Figure 16. Do not tighten the mounting cap screws or arm clevis at this time.