Model SB1269 | P R E P A R A T I O N | For Product Mfg. Since 1/10 |

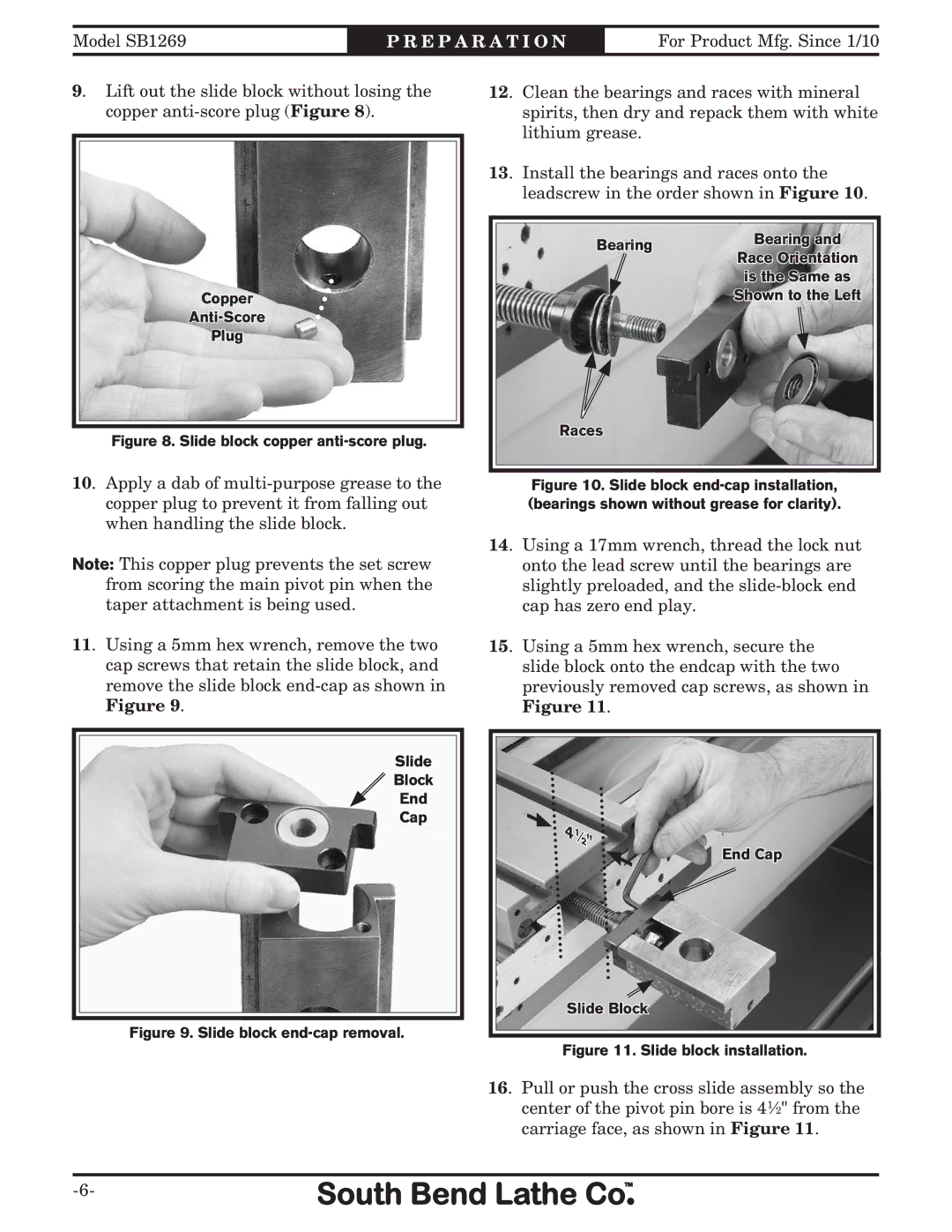

9. Lift out the slide block without losing the copper

Copper

![]() -Score

-Score

Plug

Figure 8. Slide block copper anti-score plug.

10. Apply a dab of

Note: This copper plug prevents the set screw from scoring the main pivot pin when the taper attachment is being used.

11. Using a 5mm hex wrench, remove the two cap screws that retain the slide block, and remove the slide block

Slide

Block

End

Cap

Figure 9. Slide block end-cap removal.

12. Clean the bearings and races with mineral spirits, then dry and repack them with white lithium grease.

13. Install the bearings and races onto the leadscrew in the order shown in Figure 10.

Bearing | Bearing and | |

Race Orientation | ||

| ||

| is the Same as | |

| Shown to the Left |

Races

Figure 10. Slide block end-cap installation, (bearings shown without grease for clarity).

14. Using a 17mm wrench, thread the lock nut onto the lead screw until the bearings are slightly preloaded, and the

15. Using a 5mm hex wrench, secure the slide block onto the endcap with the two previously removed cap screws, as shown in Figure 11.

⁜ |

| |

4⁄ |

| |

1 | 2" |

|

| End Cap | |

|

| |

Slide Block

Figure 11. Slide block installation.

16. Pull or push the cross slide assembly so the center of the pivot pin bore is 4⁜1⁄2" from the carriage face, as shown in Figure 11.