OPERATION

PRE-INSTALLATION INSTRUCTIONS

SKIDSTEER, BACKHOE OR EXCAVATOR SIZE

Check the Specifications section of this manual to de- termine correct carrier size, hydraulic flow and pressure requirements.

![]()

![]() WARNING

WARNING

If hydraulic pressure, hydraulic

hydraulic flow or carrier weight class are exceeded,

the tool warranty is void.

EXISTING EQUIPMENT HYDRAULICS VS. APPLICATION ATTACHING KITS

Using existing equipment hydraulic auxiliary systems for operating hydraulic tools could cause problems for the hydraulic tool and the hydraulic system if not set up properly. Simply plugging into the hydraulic system with- out confirming pressure and flow to the hydraulic tool is not a good practice. Spare spool valves, dipper circuits, etc., are just a few examples of easily accessible hy- draulic circuits which could prove to cause problems for hydraulic tool usage.

Stanley Hydraulic Tools has for many years developed ATTACHING KITS for adapting to existing hydraulic sys- tems of many popular carriers.

If your equipment does not contain an attaching kit, ask your Stanley dealer for information, installation, and pricing on a kit which matches your equipment needs.

TEST THE HYDRAULIC SYSTEM

1.Have your Stanley dealer test the carrier hydraulic system to make sure the system is operating at the manufacturers specified capacity and pressure rat- ings.

2.Be sure the fluid in the hydraulic system is filtered to at least 10

3.Check the hydraulic filter. Replace the filter if dirty or deteriorated.

4.Have your Stanley dealer test the circuit to which the breaker will be connected to make sure that the circuit is supplying the specified flow and pressure rating for the breaker. See the Specifications section of this manual.

PRE-OPERATION PROCEDURES

NITROGEN CHARGE

The breaker has been properly charged with nitrogen at the factory and is ready to use.

TOOL BIT LUBRICATION

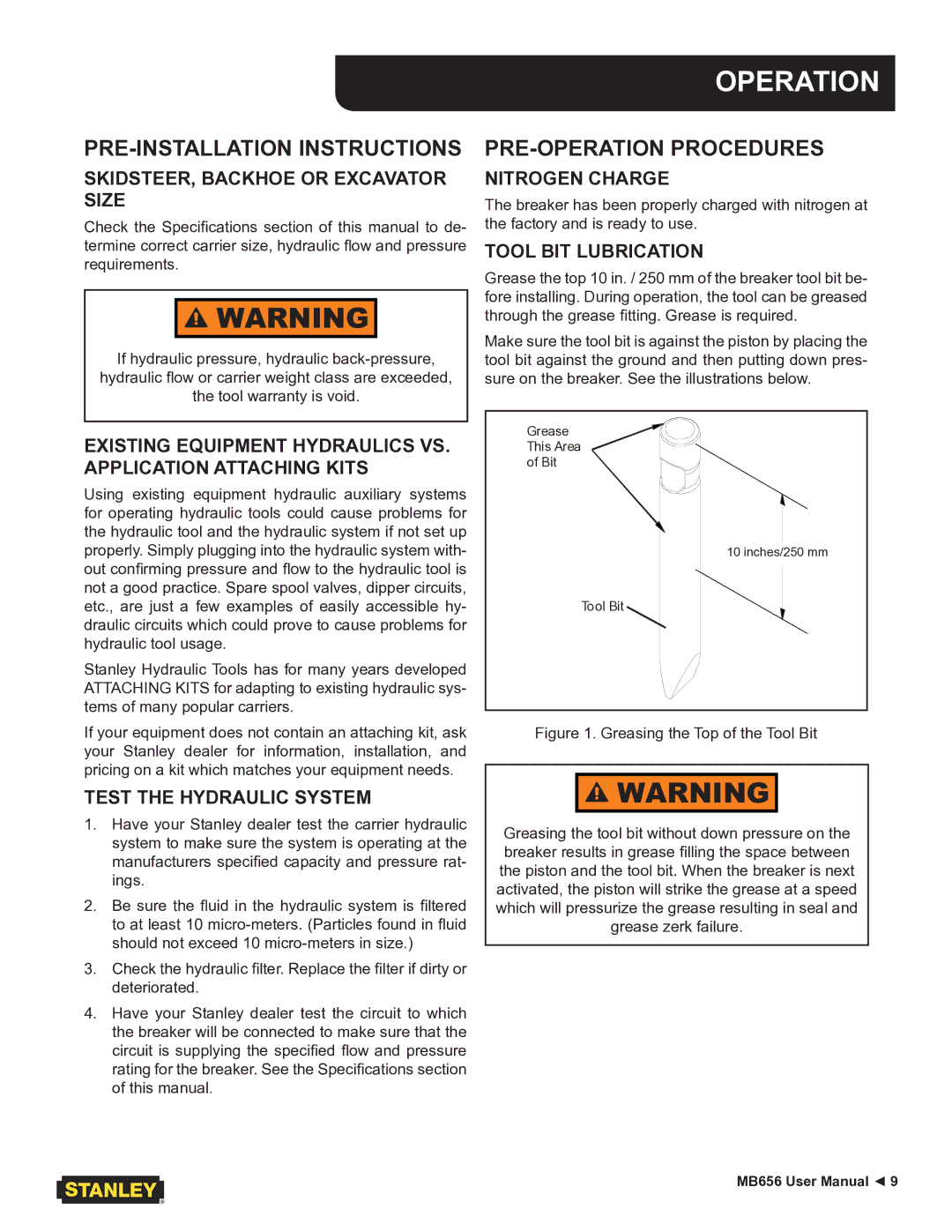

Grease the top 10 in. / 250 mm of the breaker tool bit be- fore installing. During operation, the tool can be greased through the grease fitting. Grease is required.

Make sure the tool bit is against the piston by placing the tool bit against the ground and then putting down pres- sure on the breaker. See the illustrations below.

Grease

This Area

of Bit

10 inches/250 mm

Tool Bit

Figure 1. Greasing the Top of the Tool Bit

![]()

![]() WARNING

WARNING

Greasing the tool bit without down pressure on the breaker results in grease filling the space between the piston and the tool bit. When the breaker is next activated, the piston will strike the grease at a speed which will pressurize the grease resulting in seal and

grease zerk failure.

MB656 User Manual ◄ 9