OPERATION

OVERVIEW

The RW30 is an electric arc welding controller to be used for

The RW30 after programming automatically executes the reloading of worn sections and accidental surface defects (on treads, rail butt joints, lateral wears, track devices), or the deposits of “safety stainless steel beads”.

The RW30 controls the motorized movement of the welding head in the

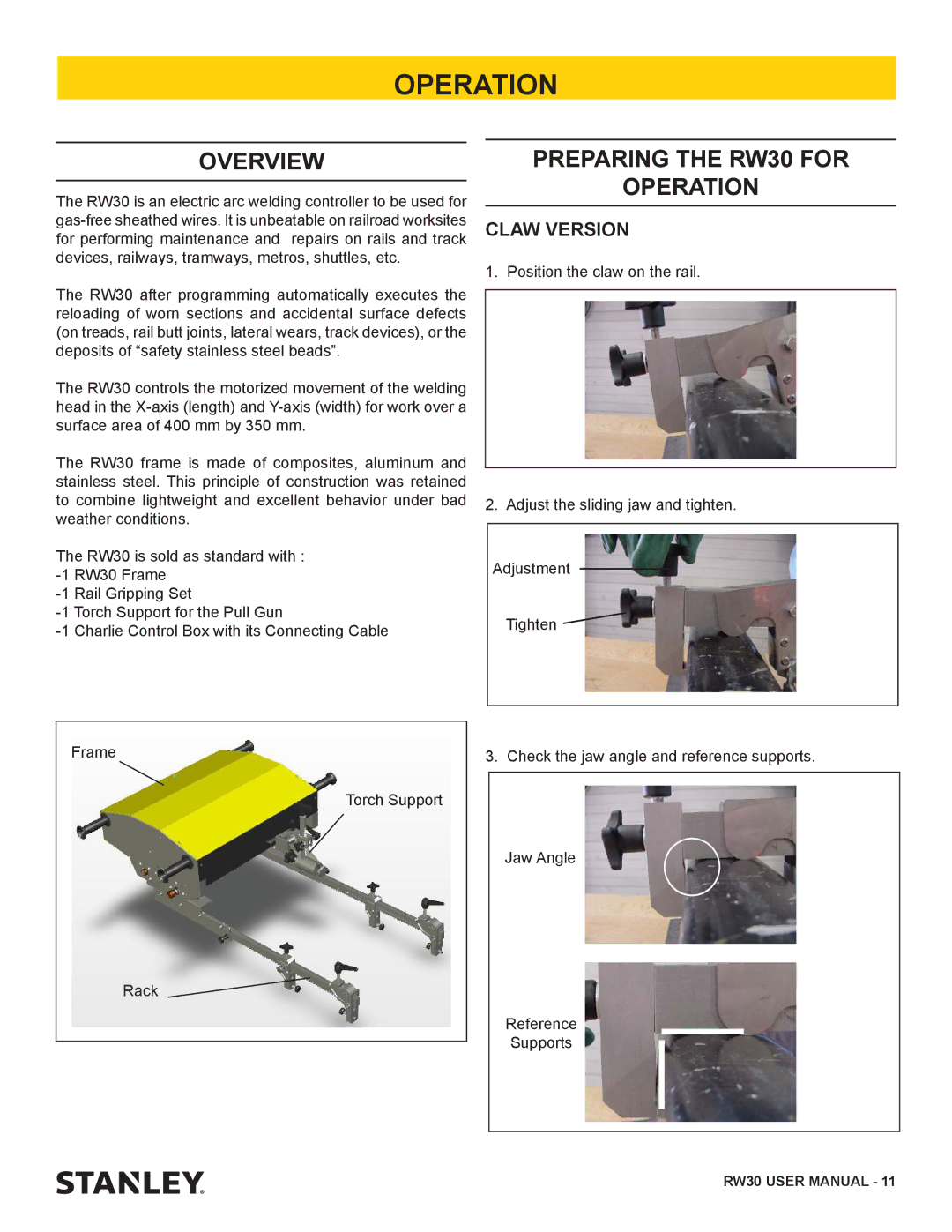

The RW30 frame is made of composites, aluminum and stainless steel. This principle of construction was retained to combine lightweight and excellent behavior under bad weather conditions.

The RW30 is sold as standard with :

Frame

Torch Support

Rack

PREPARING THE RW30 FOR

OPERATION

CLAW VERSION

1. Position the claw on the rail.

2. Adjust the sliding jaw and tighten.

Adjustment

Tighten ![]()

3.Check the jaw angle and reference supports.

Jaw Angle

Reference

Supports

RW30 USER MANUAL - 11