Minimum clearances between the water heater and combustible construction are 0 inch at the sides and rear, 5.5” (14.0 cm) from the front and 12” (30.5 cm) from the top (standard clearance). If clearances stated on the heater differ from standard clearances, install water heater according to clearances stated on the heater.

Adequate clearance 24” (61.0 cm) for servicing this appliance should be considered before installation, such as changing the anodes, etc.

A minimum clearance of 5.5” (14.0 cm) must be allowed for access to replaceable parts such as the thermostats, drain valve and relief valve.

When installing the heater, consideration must be given to proper location. Location selected should be as close to the wall as practicable and as centralized with the water piping system as possible.

A gas water heater cannot operate properly without the correct amount of air for combustion. Do not install in a confined area such as a closet, unless you provide air as shown in the “Locating The New Water Heater” section. Never obstruct the flow of ventilation air. If you have any doubts or questions at all, call your gas supplier. Failure to provide the proper amount of combustion air can result in a fire or explosion and cause death, serious bodily injury, or property damage.

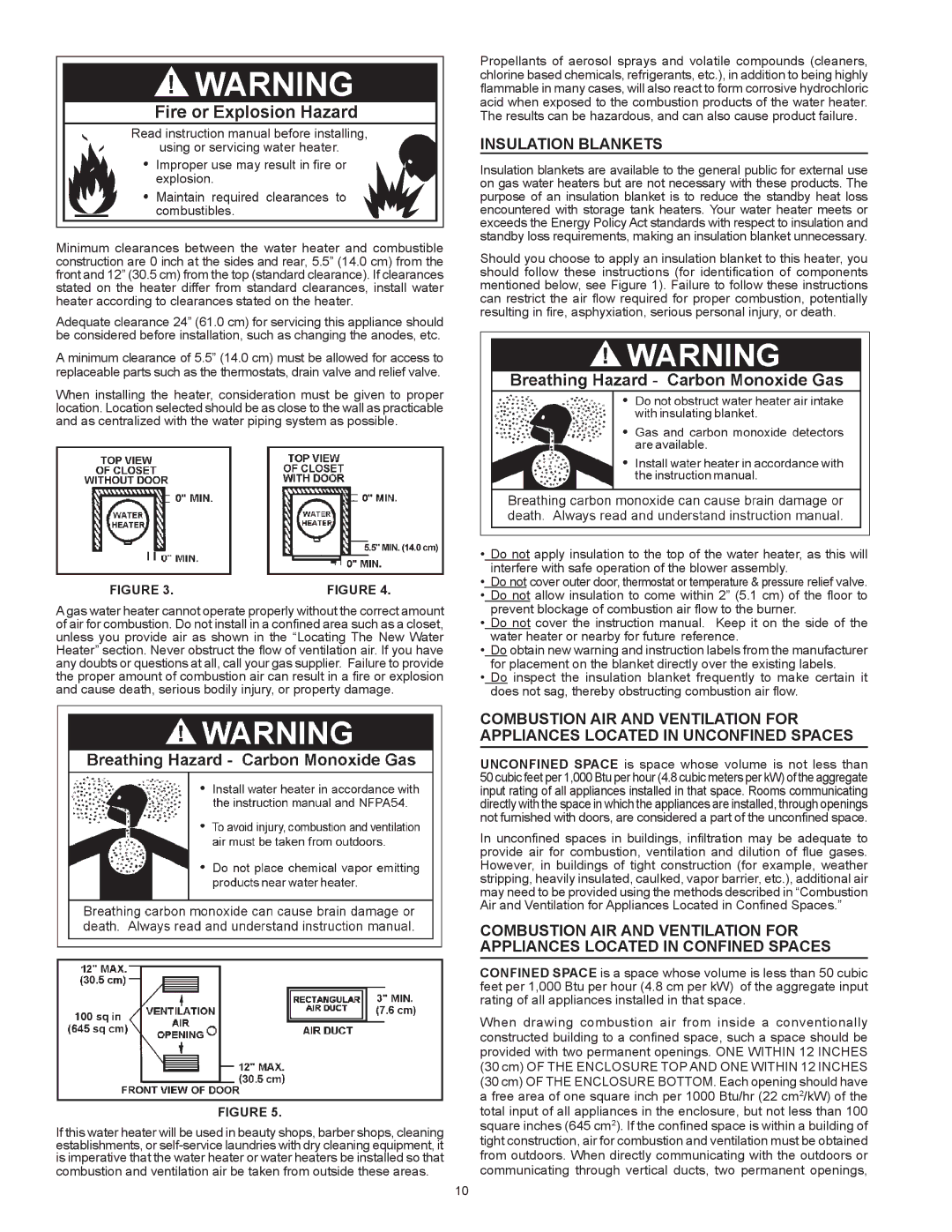

FIGURE 5.

If this water heater will be used in beauty shops, barber shops, cleaning establishments, or self-service laundries with dry cleaning equipment, it is imperative that the water heater or water heaters be installed so that combustion and ventilation air be taken from outside these areas.

Propellants of aerosol sprays and volatile compounds (cleaners, chlorine based chemicals, refrigerants, etc.), in addition to being highly flammable in many cases, will also react to form corrosive hydrochloric acid when exposed to the combustion products of the water heater. The results can be hazardous, and can also cause product failure.

INSULATION BLANKETS

Insulation blankets are available to the general public for external use on gas water heaters but are not necessary with these products. The purpose of an insulation blanket is to reduce the standby heat loss encountered with storage tank heaters. Your water heater meets or exceeds the Energy Policy Act standards with respect to insulation and standby loss requirements, making an insulation blanket unnecessary.

Should you choose to apply an insulation blanket to this heater, you should follow these instructions (for identification of components mentioned below, see Figure 1). Failure to follow these instructions can restrict the air flow required for proper combustion, potentially resulting in fire, asphyxiation, serious personal injury, or death.

•Do not apply insulation to the top of the water heater, as this will interfere with safe operation of the blower assembly.

•Do not cover outer door, thermostat or temperature & pressure relief valve.

•Do not allow insulation to come within 2” (5.1 cm) of the floor to prevent blockage of combustion air flow to the burner.

•Do not cover the instruction manual. Keep it on the side of the water heater or nearby for future reference.

•Do obtain new warning and instruction labels from the manufacturer for placement on the blanket directly over the existing labels.

•Do inspect the insulation blanket frequently to make certain it does not sag, thereby obstructing combustion air flow.

Combustion Air and Ventilation for Appliances Located in Unconfined Spaces

Unconfined Space is space whose volume is not less than 50 cubic feet per 1,000 Btu per hour (4.8 cubic meters per kW) of the aggregate input rating of all appliances installed in that space. Rooms communicating directly with the space in which the appliances are installed, through openings not furnished with doors, are considered a part of the unconfined space.

In unconfined spaces in buildings, infiltration may be adequate to provide air for combustion, ventilation and dilution of flue gases. However, in buildings of tight construction (for example, weather stripping, heavily insulated, caulked, vapor barrier, etc.), additional air may need to be provided using the methods described in “Combustion Air and Ventilation for Appliances Located in Confined Spaces.”

Combustion Air and Ventilation for Appliances Located in Confined Spaces

Confined Space is a space whose volume is less than 50 cubic feet per 1,000 Btu per hour (4.8 cm per kW) of the aggregate input rating of all appliances installed in that space.

When drawing combustion air from inside a conventionally constructed building to a confined space, such a space should be provided with two permanent openings. ONE WITHIN 12 INCHES (30 cm) OF THE ENCLOSURE TOP AND ONE WITHIN 12 INCHES (30 cm) OF THE ENCLOSURE BOTTOM. Each opening should have a free area of one square inch per 1000 Btu/hr (22 cm2/kW) of the total input of all appliances in the enclosure, but not less than 100 square inches (645 cm2). If the confined space is within a building of tight construction, air for combustion and ventilation must be obtained from outdoors. When directly communicating with the outdoors or communicating through vertical ducts, two permanent openings,