STT 110 / STT 160

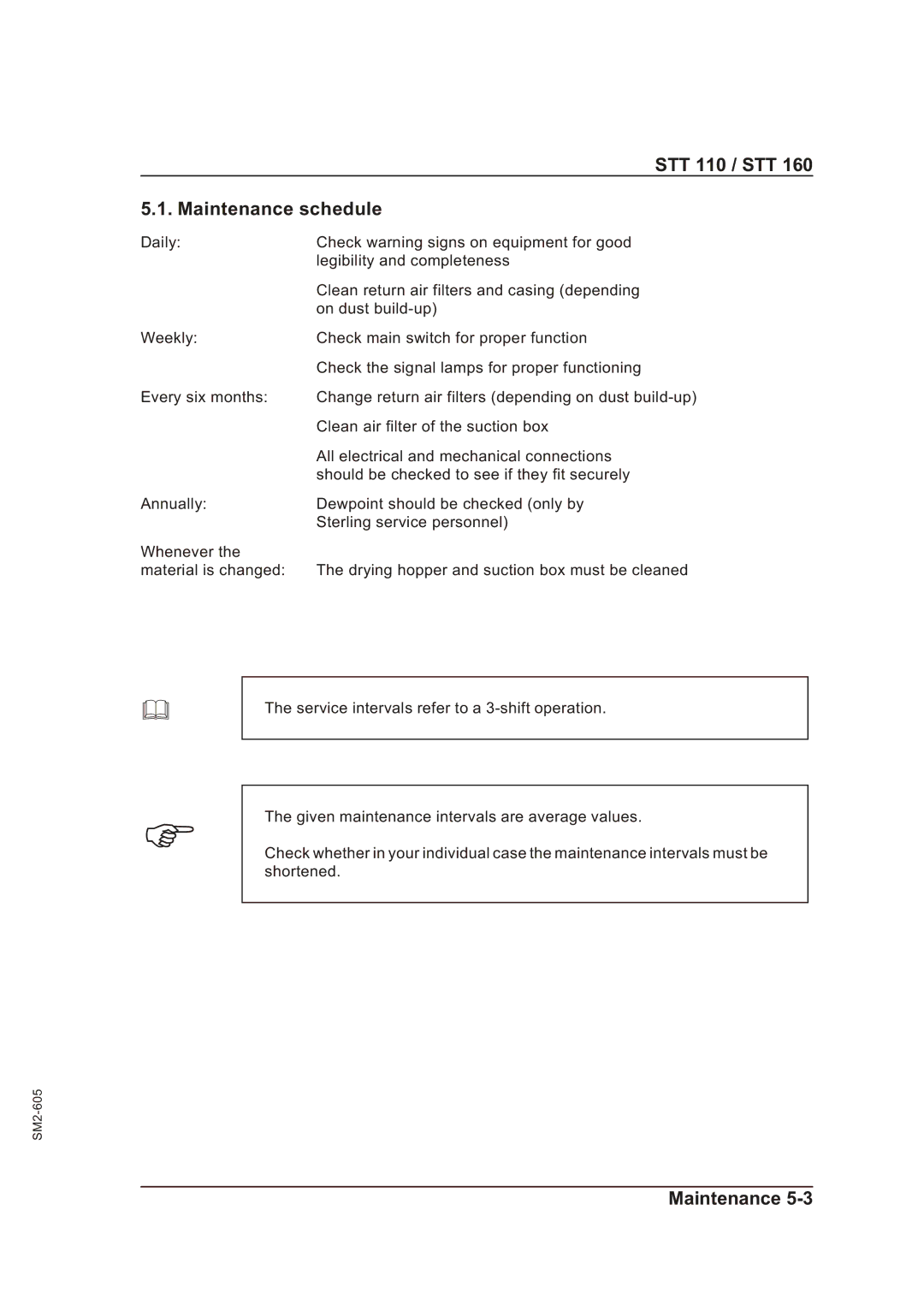

5.1. Maintenance schedule

Daily: | Check warning signs on equipment for good |

| legibility and completeness |

| Clean return air filters and casing (depending |

| on dust |

Weekly: | Check main switch for proper function |

| Check the signal lamps for proper functioning |

Every six months: | Change return air filters (depending on dust |

| Clean air filter of the suction box |

| All electrical and mechanical connections |

| should be checked to see if they fit securely |

Annually: | Dewpoint should be checked (only by |

| Sterling service personnel) |

Whenever the |

|

material is changed: | The drying hopper and suction box must be cleaned |

&

F

The service intervals refer to a

The given maintenance intervals are average values.

Check whether in your individual case the maintenance intervals must be shortened.