STT 110 / STT 160

6.3. Connection to a Pneumatic Conveying System (Optional)

Your drying facility works best in combination with a pneumatic conveying system. In this way, your drying hopper will always be supp- lied with sufficient material.

The facility will only take as much material as is required by the processing machines. The- refore, the drying result will always be the same.

Sterling drying hoppers are equipped with a suitable flange for adding a Sterling pneuma- tic conveyor.

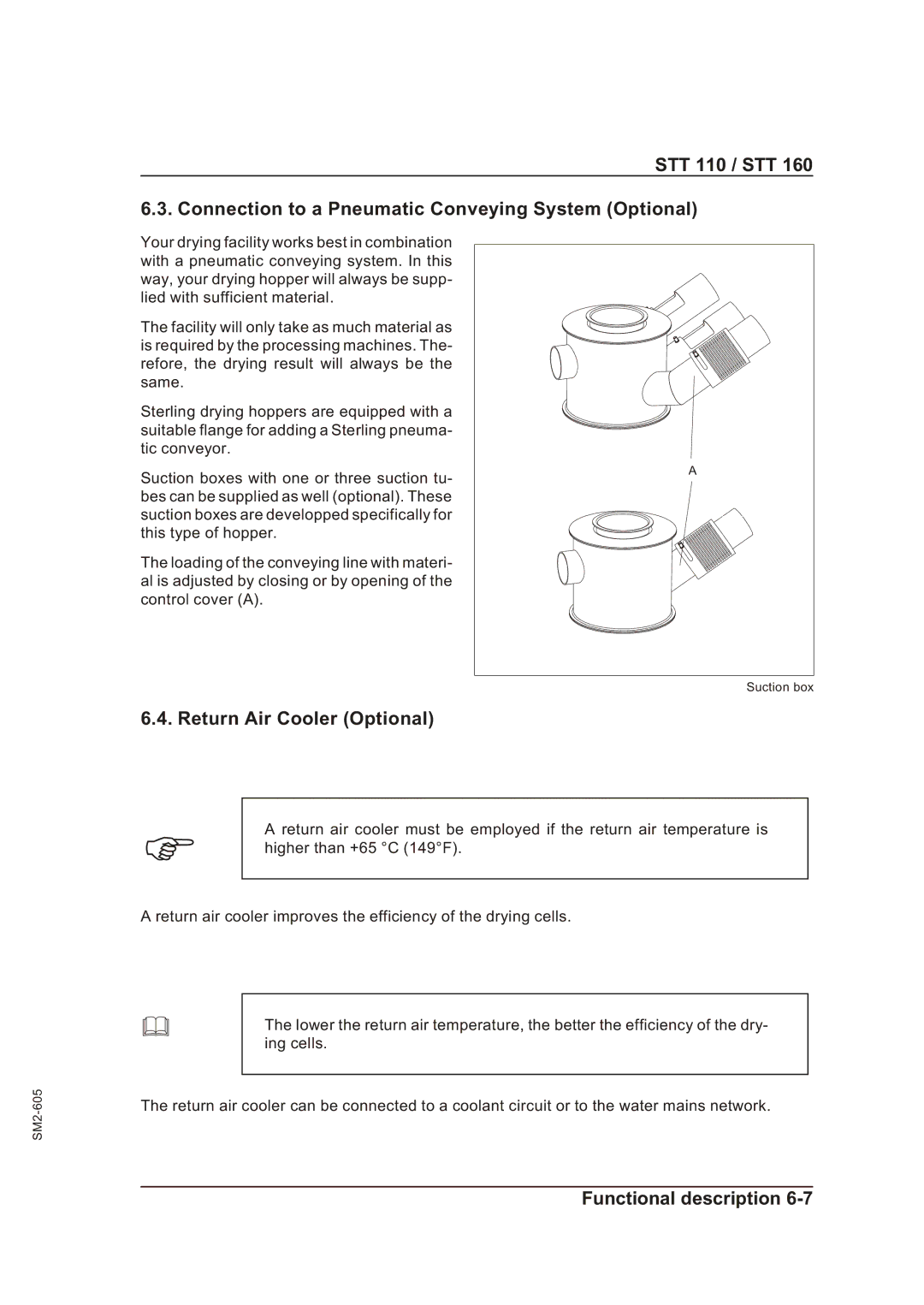

Suction boxes with one or three suction tu- bes can be supplied as well (optional). These suction boxes are developped specifically for this type of hopper.

The loading of the conveying line with materi- al is adjusted by closing or by opening of the control cover (A).

6.4. Return Air Cooler (Optional)

A

Suction box

F | A return air cooler must be employed if the return air temperature is |

higher than +65 °C (149°F). |

A return air cooler improves the efficiency of the drying cells.

& | The lower the return air temperature, the better the efficiency of the dry- |

| ing cells. |

|

|

The return air cooler can be connected to a coolant circuit or to the water mains network.