WALK-BEHIND Trowel SCT36 and SCT46 Series

Page

Page

SCT SERIESTROWEL-TABLE of Contents

When ordering parts Please supply the following information

SCT SERIESTROWEL- Parts Ordering Procedures

SCT SERIESTROWEL-TRAINING Checklist

Daily PRE-OPERATION Checklist

SCT SERIESTROWEL- Daily PRE-OPERATION Checklist

SCT SERIESTROWEL- Safety Message Alert Symbols

SCT SERIESTROWEL- Safety Message Alert Symbols

SCT Seriestrowel Rules for Safe Operation

Safety

Emergencies

Maintenance Safety

SCT SERIESTrowel Decals

Machine Safety Decals

SideView Top View

SCT Seriestrowel Specifications Trowel

Model SCT36 SCT46

See Table

SCT SERIESTROWEL- Specifications Engines

Gearbox

Centrifugal Stop Switch

SCT SERIESWalk-BehindTrowel Familiarization

Engines Drive System

SCT SERIESTROWEL- Controls and Components

SCT SERIESTROWEL- Basic Engine

Handle Tube Installation

Assembly and Installation

Engine Safety Stop Wire Connection Pitch Cable Installation

Safety StopWire

Engine Oil Check

Before Starting

Gearbox Oil

Safety Stop Switch

CentrifugalType Safety Stop Switch

Fuel Check

Starting the Engine

Lifting Bail

SCT Seriestrowel Initial START-UP

Pitching the Blades

SCT Seriestrowel Operation

Clip-On Float Blades Optional

Combo Blades

Engine Maintenance

SCT Seriestrowel Maintenance Engine

Spark Plug Gap

Engine Air Cleaner

Monthly 200-300 Hours

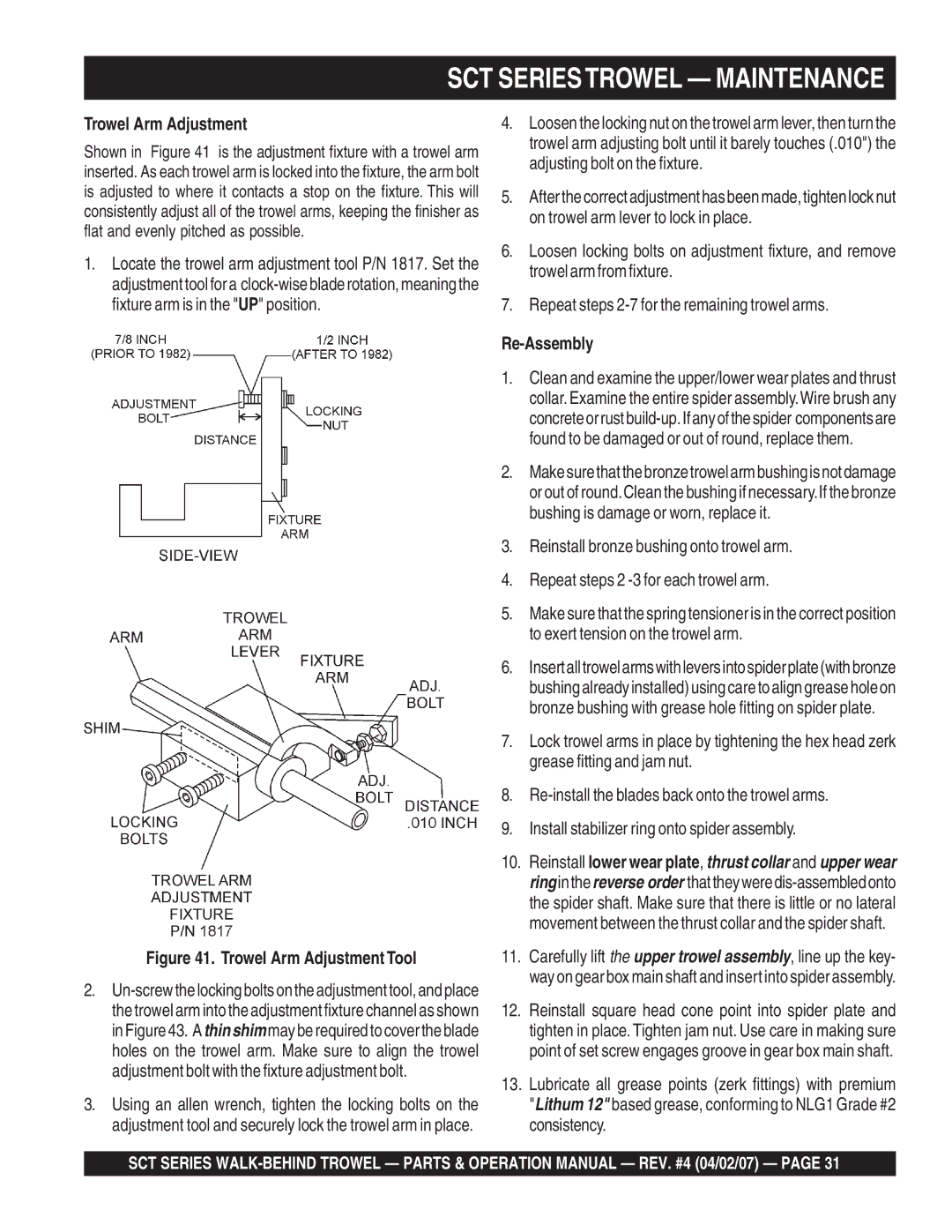

Trowel Arm Adjustment Procedure

Daily 8-10 Hours

Weekly 50-60 Hours

Trowel Arm Removal

Spider Removal

Trowel Arm Flatness Test

Bronze Bushings Trowel Blade Removal

Re-Assembly

Trowel Arm Adjustment

Belt Inspection and Replacement

Testing

Changing a Blade

Trowel Troubleshooting

SCT Seriestrowel Troubleshooting Trowel

SCT Seriestrowel Troubleshooting Trowel

Difficult to start

SCT Seriestrowel Troubleshooting Engine

Remarks Column

NO. Column

Part NO. Column

QTY. Column

To 3 Units

Nameplates and Decals

SCT Seriestrowel Decal Locator

Parts Dept

Decal CAUTION, Safety Straps

Nameplate and Decals

Contact Multiquip

Standard Handle Detail a

SCT Seriestrowel Standard Handle

GRIP, Handle

LEVER, Throttle Assembly

Switch ASSEMBLY, Safety Stop

Handle Assembly

Blade Spider Assy

SCT Seriestrowel 4-BLADE Spider Assy

Wear Plate

Wear Ring

Flange Bearing

Thrust Collar Bushing

Gearbox Assy

SCT Seriestrowel Gearbox Assy

SCT Seriestrowel Gearbox Assy

Guard Ring Assy

SCT Seriestrowel Guard Ring Assy

Part Name QTY. Remarks

SCT Seriestrowel Stabilizer Ring Assy

Part Name QTY

ENGINE, 5.5 HP, 8 HP, 11 HP Honda Assy

SCT Series Trowel ENGINES, 5.5 HP, 8 HP, 11 HP Honda Assy

Weight SET Includes 4 Weights

WIRE, Safety Switch

Connector Splice

Clutch Housing Drum

Blades & Adjustment Fixture Assy

Guard Ring LUG Ring

AIR Cleaner Assy

Honda GX160K1QX2 AIR Cleaner Assy

COLLAR, AIR Cleaner

ELEMENT, AIR Cleaner Dual

COVER, AIR Cleaner Dual

GROMMET, AIR Cleaner

Camshaft Assy

Honda GX160K1QX2 Camshaft Assy

ARM, Valve Rocker

Camshaft Assembly

SPRING, Weight Return

ROD, Push

Carburetor Assy

Honda GX160K1QX2 Carburetor Assy

SN BE65B B

Gasket SET

Valve SET, Float

Float SET

Control Assy

Honda GX160K1QX2 Control Assy

SPRING, Levr

ROD, Governor

Spring Governor

LEVER, Control

Crankcase Cover Assy

Honda GX160K1QX2 Crankcase Cover Assy

BOLT, Flange 8 X

CAP ASSEMBLY, OIL Filler

GASKET, OIL Filler CAP

PIN A, Dowel 8 X

Crankshaft Assy

Honda GX160K1QX2 Crankshaft Assy

CRANKSHAFT, Q- Type

Cylinder Barrel Assy

Honda GX160K1QX2 Cylinder Barrel Assy

BOLT, Drain Plug

WEIGHT, Governor

SLIDER, Governor

SHAFT, Governor ARM

Cylinder Head Assy

Honda GX160K1QX2 Cylinder Head Assy

COVER, Head

GUIDE, Valve OS Optional

CLIP, Valve Guide

GASKET, Cylinder Head

FAN Cover Assy

Honda GX160K1QX2 FAN Cover Assy

Shroud

COVER, FAN NH1 Black

PLATE, Side OIL Alert

CLIP, Harness

Flywheel Assy

Honda GX160K1QX2 Flywheel Assy

FLYWHEEL, Lamp

FAN, Cooling

PULLEY, Starter

Flywheel

Fuel Tank Assy

Honda GX160K1QX2 Fueltank Assy

TANK, Fuel *NH1* Black

RUBBER, Supporter 107MM

JOINT, Fuel Tank

TANK, Fuel *R8* Bright RED

Ignition Coil Assy

Honda GX160K1QX2 Ignition Coil Assy

WIRE, Stop Switch 370MM

Coil ASSEMBLY, Ignition

Muffler Assy

Honda GX160K1QX2 Muffler Assy

ARRESTER, Spark Optional

Muffler

Muffler Optional

PROTECTOR, Muffler

Piston Assy

Honda GX160K1QX2 Piston Assy

Piston OS 0.25, Optional

ROD ASSEMBLY, Connecting

BOLT, Connecting ROD

Piston Standard

Recoil Starter Assy

Honda GX160K1QX2 Recoil Starter Assy

GUIDE, Ratchet

SCREW, Setting

REEL, Recoil Starter

RATCHET, Starter

Page

Gasket KIT Assy

Honda GX160K1QX2 Gasket KIT Assy

Engine Labels Assy

Honda GX160K1QX2 Engine Labels Assy

MARK, OIL Alert E

LABEL, Specification External

LABEL, Caution

MARK, Choke

Honda GX240K1QA2 Engine AIR Cleaner Assy

BOLT- Washer 6 X

COVER, AIR Cleaner

Honda GX240K1QA2 Engine Camshaft Assy

Pivot Rocker ARM

ROD Push

ARM Valve Rocker

Lifter Valve

Honda GX240K1QA2 Engine Carburetor Assy

Screw SET B

PLATE, Lever Setting

Screw SET

Screw SET, Drain

Honda GX240K1QA2 Engine Control Assy

SPRING, Lever

ARM, Governor

SPRING, Governor

SPRING, Throttle Return

Honda GX240K1QA2 Engine Crankcase Cover Assy

Washer 6 X

HOLDER, Governor Weight

PIN, Governor Weight

GASKET, Case Cover

Honda GX240K1QA2 Engine Crankshaft Assy

WEIGHT, Balancer

Honda GX240K1QA2 Engine Cylinder Barrel Assy

BOLT, Flange 6X12 CT200

OIL Seal

WASHER, Drain Plug 12MM

PIN, Lock 10MM

Honda GX240K1QA2 Engine Cylinder Head Assy

SEAT, Valve Spring

GUIDE, VALVE, OS, Optional

GUIDE, EX. VALVE, OS, Optional

Cover COMP., Head

Honda GX240K1QA2ENGINE FAN Cover Assy

SUB-HARNESS

Switch ASSY., Engine Stop

CLIP, Wire Harness

CLIP, Tube

Honda GX240K1QA2 Engine Flywheel Assy

NUT, Special 16MM

Flywheel Comp

KEY, Special Woodruff

Honda GX240K1QA2ENGINE Fueltank Assy

Ring 14MM, Arai

Rubber Supporter 107MM

Tank COMP., Fuel *NH1*, Black

FILTER, Fuel

Honda GX240K1QA2 Engine Ignition Coil Assy

Coil ASSY., Ignition

GROMMET, Wire

CAP ASSY., Noise Suppressor

Honda GX240K1QA2 Engine Muffler Assy

PIPE, EX

Muffler Comp

Protector COMP., Muffler

PROTECTOR, EX. Pipe

Honda GX240K1QA2 Engine Piston Assy

PISTON, OS 0.25, Optional

Ring SET, PISTON, STD

Ring SET, PISTON, 0.75, Optional

PISTON, Standard

Honda GX240K1QA2 Engine Recoil Starter Assy

RETAINER, Spring

PULLEY, Recoil Starter

SPRING, Starter Return

Spring Ratchet

Engine Labels

Honda GX240K1QA2 Engine Engine Labels

MARK, CHOKE, External

EMBLEM, Internal

MARK, OIL ALERT, E

Honda GX-340K1QAP2 Engine AIR Cleaner Assy

Wingnut 6MM

NOSE, Muffler

Honda GX-340K1QAP2 Engine Camshaft Assy

SEAL, Valve Stem

Honda GX-340K1QAP2 Engine Carburetor Assy

JET, Main #88 Optional

Chamber SET, Float

GASKET, Fuel Strainer CUP

PIN, Spring 2

Honda GX-340K1QAP2 Engine Crankcase Cover Assy

PIN, Dowel

Honda GX-340K1QAP2 Engine Control Assy

No ART Work Available

Washer Control Lever

SPRING, Control Adjusting

HOLDER, Wire

SPRING, Govrnor

Honda GX-340K1QAP2 Engine Cylinder Barrel Assy

Switch Assembly OIL Level

Honda GX-340K1QAP2 Engine Cylinder Head Assy

WASHER, Head Cover

12200ZF6W00

Honda GX-340K1QAP2 Engine Crankshaft Assy

13310ZE3601

Honda GX-340K1QAP2 Engine FAN Cover Assy

COVER, FAN *NH1* Black

Honda GX-340K1QAP2 Engine Flywheel Assy

19511ZE3000

Honda GX-340K1QAP2 Engine Fueltank Assy

TANK, Fuel NH1 Black

Joint Fuel Tank

Honda GX-340K1QAP2 Engine Ignition Coil Assy

Coil ASSEMBYL, Ignition

WIRE, Stop Switch 430MM

Honda GX-340K1QAP2 Engine Muffler Assy

PIPE, Exhaust

PROTECTOR, Exhaust Pipe

GASKET, Exhaust Pipe

Honda GX-340K1QAP2 Engine Piston Assy

CLIP, Piston PIN 20MM

Ring SET, Piston Standard

Ring SET, Piston OS

Ring SET, Piston

Honda GX-340K1QAP2 Engine Recoil Starter Assy

GRIP, Reinforcement

Black

SPRING, Ratchet

HOLDER, Spring

Honda GX-340K1QAP2 Engine Engine Labels Assy

MARK, Choke External

Emblem

WRENCH, Spark Plug

Terms and Conditions of Sale

Page

Heres HOW to GET Help