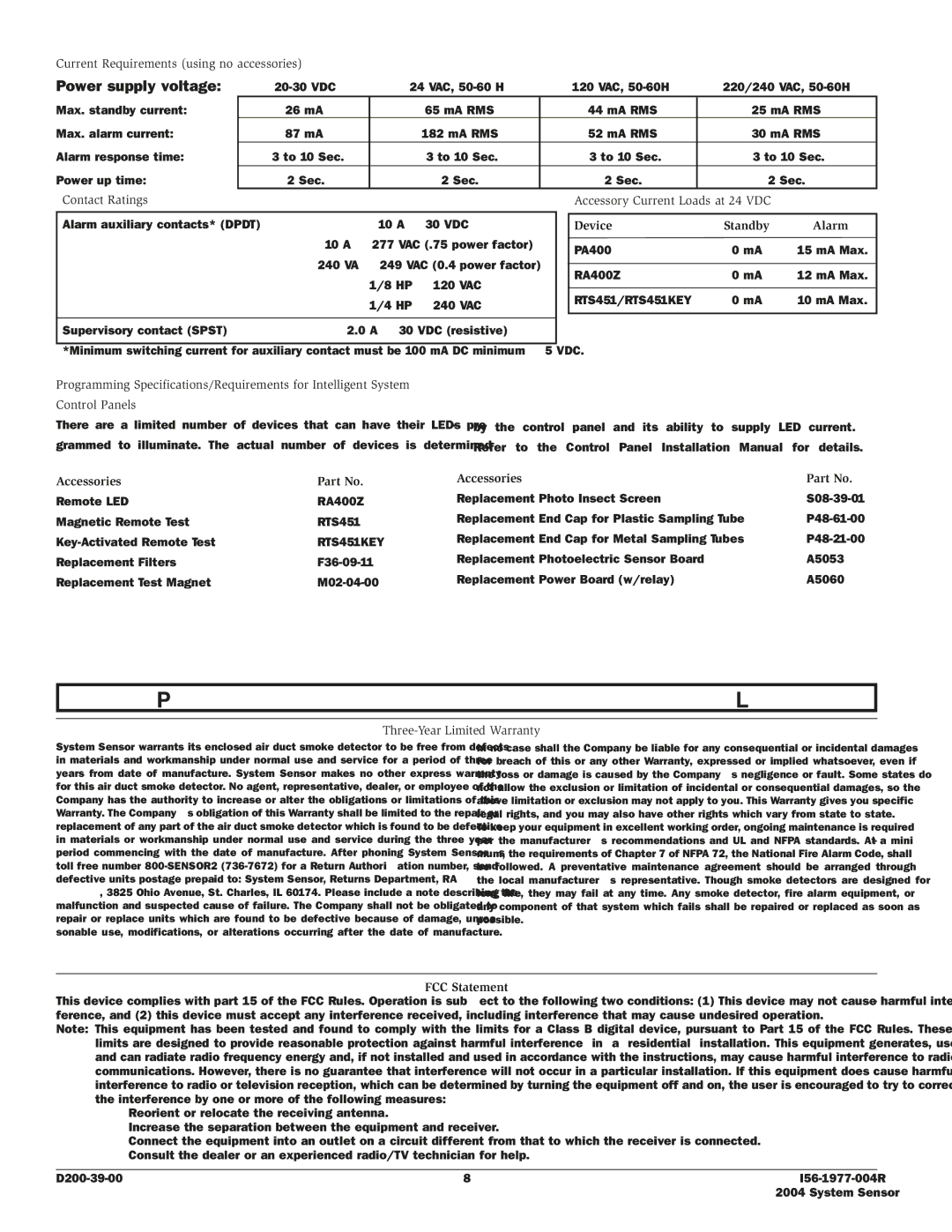

Current Requirements (using no accessories)

Power supply voltage: | 20-30 VDC | 24 VAC, 50-60 Hz | 120 VAC, 50-60Hz | 220/240 VAC, 50-60Hz |

Max. standby current: | 26 mA | 65 mA RMS | 44 mA RMS | 25 mA RMS |

Max. alarm current: | 87 mA | 182 mA RMS | 52 mA RMS | 30 mA RMS |

Alarm response time: | 3 to 10 Sec. | 3 to 10 Sec. | 3 to 10 Sec. | 3 to 10 Sec. |

Power up time: | 2 Sec. | 2 Sec. | 2 Sec. | 2 Sec. |

Contact Ratings

Alarm auxiliary contacts* (DPDT) | 10 A @ 30 VDC |

| 10 A @ 277 VAC (.75 power factor) |

| 240 VA @ 249 VAC (0.4 power factor) |

| 1/8 HP @ 120 VAC |

| 1/4 HP @ 240 VAC |

| |

Supervisory contact (SPST) | 2.0 A @ 30 VDC (resistive) |

*Minimum switching current for auxiliary contact must be 100 mA DC minimum @ 5 VDC.

Accessory Current Loads at 24 VDC

Device | Standby | Alarm |

PA400 | 0 mA | 15 mA Max. |

| | |

RA400Z | 0 mA | 12 mA Max. |

| | |

RTS451/RTS451KEY | 0 mA | 10 mA Max. |

| | |

Programming Specifications/Requirements for Intelligent System Control Panels

There are a limited number of devices that can have their LEDs pro- grammed to illuminate. The actual number of devices is determined

by the control panel and its ability to supply LED current. Refer to the Control Panel Installation Manual for details.

Accessories | Part No. |

Remote LED | RA400Z |

Magnetic Remote Test | RTS451 |

Key-Activated Remote Test | RTS451KEY |

Replacement Filters | F36-09-11 |

Replacement Test Magnet | M02-04-00 |

Accessories | Part No. |

Replacement Photo Insect Screen | S08-39-01 |

Replacement End Cap for Plastic Sampling Tube | P48-61-00 |

Replacement End Cap for Metal Sampling Tubes | P48-21-00 |

Replacement Photoelectric Sensor Board | A5053 |

Replacement Power Board (w/relay) | A5060 |

Please refer to insert for the Limitations of Fire Alarm Systems

Three-Year Limited Warranty

System Sensor warrants its enclosed air duct smoke detector to be free from defects in materials and workmanship under normal use and service for a period of three years from date of manufacture. System Sensor makes no other express warranty for this air duct smoke detector. No agent, representative, dealer, or employee of the Company has the authority to increase or alter the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the repair or replacement of any part of the air duct smoke detector which is found to be defective in materials or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization number, send defective units postage prepaid to: System Sensor, Returns Department, RA #______

____, 3825 Ohio Avenue, St. Charles, IL 60174. Please include a note describing the

malfunction and suspected cause of failure. The Company shall not be obligated to repair or replace units which are found to be defective because of damage, unrea- sonable use, modifications, or alterations occurring after the date of manufacture.

In no case shall the Company be liable for any consequential or incidental damages for breach of this or any other Warranty, expressed or implied whatsoever, even if the loss or damage is caused by the Company’s negligence or fault. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

To keep your equipment in excellent working order, ongoing maintenance is required per the manufacturer’s recommendations and UL and NFPA standards. At a mini- mum, the requirements of Chapter 7 of NFPA 72, the National Fire Alarm Code, shall be followed. A preventative maintenance agreement should be arranged through the local manufacturer’s representative. Though smoke detectors are designed for long life, they may fail at any time. Any smoke detector, fire alarm equipment, or any component of that system which fails shall be repaired or replaced as soon as possible.

FCC Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful inter- ference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

–Reorient or relocate the receiving antenna.

–Increase the separation between the equipment and receiver.

–Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

–Consult the dealer or an experienced radio/TV technician for help.

D200-39-00 | 8 | I56-1977-004R |

| | © 2004 System Sensor |