Trace Oxygen Analyzer | Installation | |

|

|

|

The

Table |

|

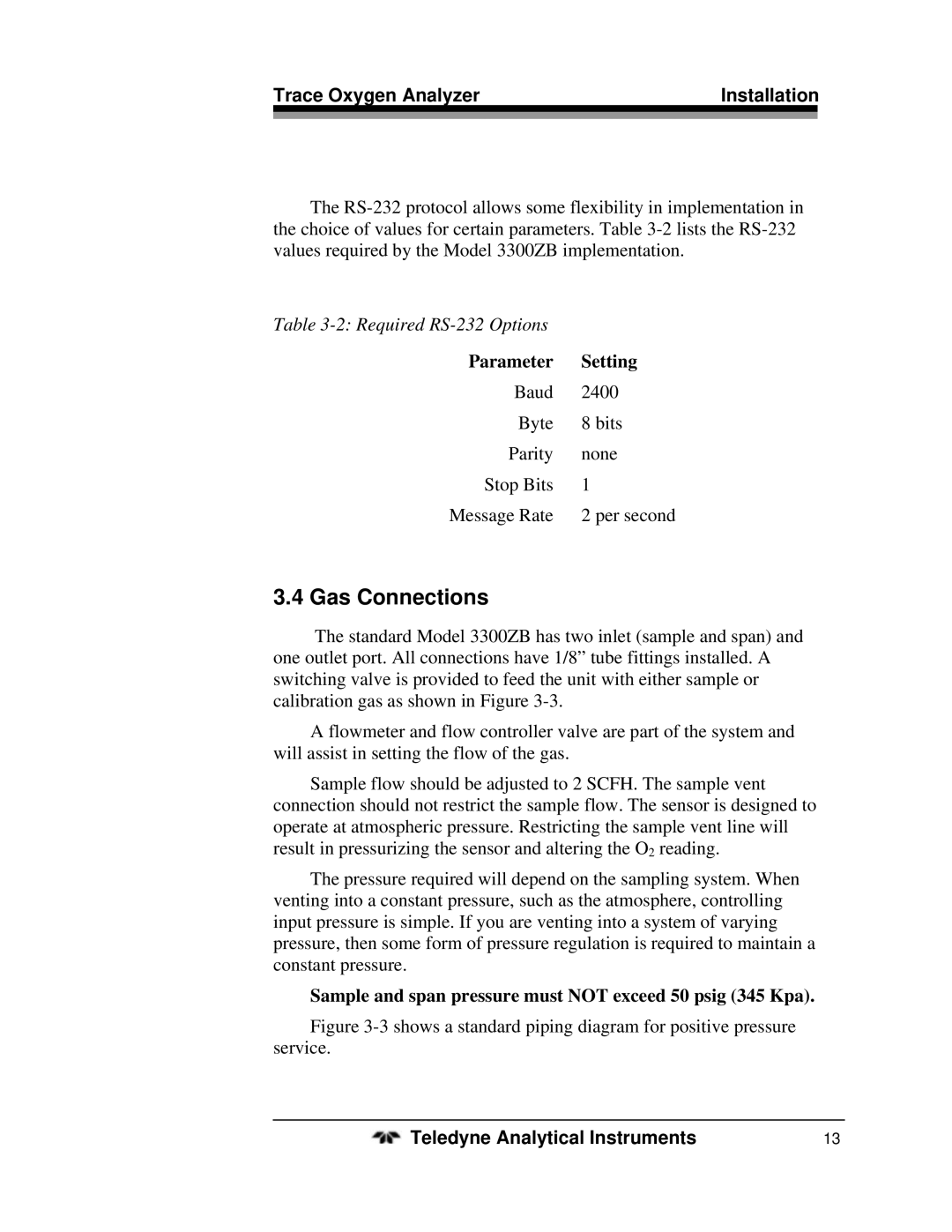

Parameter | Setting |

Baud | 2400 |

Byte | 8 bits |

Parity | none |

Stop Bits | 1 |

Message Rate | 2 per second |

3.4 Gas Connections

The standard Model 3300ZB has two inlet (sample and span) and one outlet port. All connections have 1/8” tube fittings installed. A switching valve is provided to feed the unit with either sample or calibration gas as shown in Figure

A flowmeter and flow controller valve are part of the system and will assist in setting the flow of the gas.

Sample flow should be adjusted to 2 SCFH. The sample vent connection should not restrict the sample flow. The sensor is designed to operate at atmospheric pressure. Restricting the sample vent line will result in pressurizing the sensor and altering the O2 reading.

The pressure required will depend on the sampling system. When venting into a constant pressure, such as the atmosphere, controlling input pressure is simple. If you are venting into a system of varying pressure, then some form of pressure regulation is required to maintain a constant pressure.

Sample and span pressure must NOT exceed 50 psig (345 Kpa).

Figure 3-3 shows a standard piping diagram for positive pressure service.

Teledyne Analytical Instruments | 13 |