SX6T Series

CE Compliance for EU only

Vorsicht

SX6T Series

Waste Recycling information for users

For all countries and areas

Safety Summary

Meanings of Each Symbol

Precautions

Request Regarding Maintenance

Table of Contents

EA3-1

EA1-1

EA2-1

EA4-1

Introduction Features

Product Overview

Supply Holder Frame L

Accessories

Wing Bolt 2 pcs

Front View

Dimensions

Appearance

Rear View

Operation Panel

Interior

Options

Option Name Type Usage

Procedure

Printer Setup

Setup Flow

Manual threshold setting

Installation

Assembling the Supply Holder Frame

Connecting the Power Cord

Example of US Type

Loading the Media

Set the Head Lever to the Open position

Open the Top Cover and the Right Side Cover

Media Guide Media Guide Screw Supply Holder Frame

Detail of Movable Sensor

Fixed sensor Movable sensor

Detail of Fixed Sensor

Feed Gap Sensor position adjustment

Black Mark Sensor position adjustment

Batch mode

Close the Top Cover and Right Side Cover

Strip mode Option

Cut mode Option

Label or Thin media

Tag paper or Thick paper

Loading the Ribbon

Loading the Ribbon

Close the Head Lock Plate, Right Side Cover, and Top Cover

Connecting the Printer to Your Host Computer

Turning the Printer

How to enter the System Mode

Time the Pause key is pressed, the sub menus are displayed

Parameter Setting

While 2PARAMETER SET is displayed on the LCD Message

Sequentially

Use the Feed or Restart key to select a desired option

Character Zero Selection

Character Code Selection

After selecting a character code, press the Pause key

Data Length Selection

Baud Rate Selection

After selecting a baud rate, press the Pause key

After selecting a data length, press the Pause key

Parity Selection

Stop Bit Length Selection

Flow Control Code Selection

Auto Forward Wait Selection

LCD Language Selection

After selecting a language, press the Pause key

After selecting an auto forward wait, press the Pause key

Head Up Cut Selection

Ribbon Save Function Selection

Control Code Selection

Ribbon Type Selection

After selecting a ribbon type, press the Pause key

Feed Key Function Selection

Strip Wait Status Selection

After selecting the Strip Wait Status, press the Pause key

After selecting the Feed key function, press the Pause key

Euro Code Selection

Kanji Code Selection

After selecting a Kanji code, press the Pause key

After selecting a Euro code, press the Pause key

Centronics Interface ACK/BUSY Timing Selection

Auto Print Head Check Selection

After selecting auto print head check, press the Pause key

After selecting an ACK/BUSY timing, press the Pause key

Media Sensor Selection

Web Printer Function Selection

After selecting the media sensor type, press the Pause key

After selecting the Input Prime, press the Pause key

Input Prime Selection

Expansion I/O Interface Type Selection

After selecting a Plug & Play, press the Pause key

Plug & Play Selection

Label End/Ribbon End Selection

Reverse Feed Speed Selection

Pre-Strip Selection

This parameter is fixed to OFF Press the Pause key

After selecting the Back Feed Speed, press the Pause key

This parameter is fixed to R0 Press the Pause key

Maxi Code Specification Selection

Strip Motor Torque Selection

Stabilizer Function Selection

Use the Feed or Restart key to select a printing method

Dump Mode Setting

After selecting the receive buffer, press the Pause key

After selecting a printing method, press the Pause key

Receive Buffer Size

Data in the receive buffer is printed as follows

Required Label Length

When the Pause key is pressed, Basic program is executed

Automatic Calibration

Press the Pause key to enter the Automatic Calibration Mode

When 6AUTO Calib appears, press the Pause key

While 6AUTO Calib is displayed on the LCD Message Display

LAN Setting

Date Setting

Time Setting

RTC Data Renewal Timing Setting

Real Time Clock Setting 3 Low Battery Check Setting

Cont

IP Address Setting TCP/IP

Feed and Pause keys

Gateway IP Address

Printer IP Address

This parameter is to set an IP address

This parameter is to set a Gateway IP address

This parameter is to set a Subnet Mask

Subnet Mask

Socket Port

Dhcp Client ID

This parameter is to enable Dhcp

Dhcp

This parameter is to set a Dhcp client ID

This parameter is to set a Dhcp host name

Dhcp Host Name

Ascii code and Hex. code correspondence table

Introduction

Installing the Printer Drivers

General Description

Installing the Printer Driver

Parallel Interface

Windows 98/Me

E2-52

Windows 2000/XP

E2-54

USB Interface

E2-56

E2-57

E2-58

Finish button

E2-60

E2-61

E2-62

Uninstalling the Printer Driver

Adding/Deleting a LAN Port

Adding a LAN Port Windows 98/ME

Deleting a LAN Port

Printer Driver Upgrades

Others

Using the Printer Driver

Adjustment

Print Test

When using an optional Cutter Module or Strip Module

Cut/Strip Position Fine Adjustment

Position and Print Tone Fine Adjustment

Feed Amount Fine Adjustment

Coordinate Fine Adjustment

Position and Print

When setting +0.0 mm

Tone Fine

Example of Cut Position Fine Adjustment

Example of Strip Position Fine Adjustment

Restart Feed

When setting -50.0 mm

When setting +50.0 mm

Position and Print Tone Fine Adjustment

Ribbon Motor Voltage Fine Adjustment

Select the sensor to be adjusted by using the Feed key

Threshold Setting

Jam errors

Manually set

Black Mark Sensor/Feed Gap Sensor Adjustment No media

Black Mark Sensor Adjustment

Feed Gap Sensor Adjustment

Ribbon End Sensor Adjustment

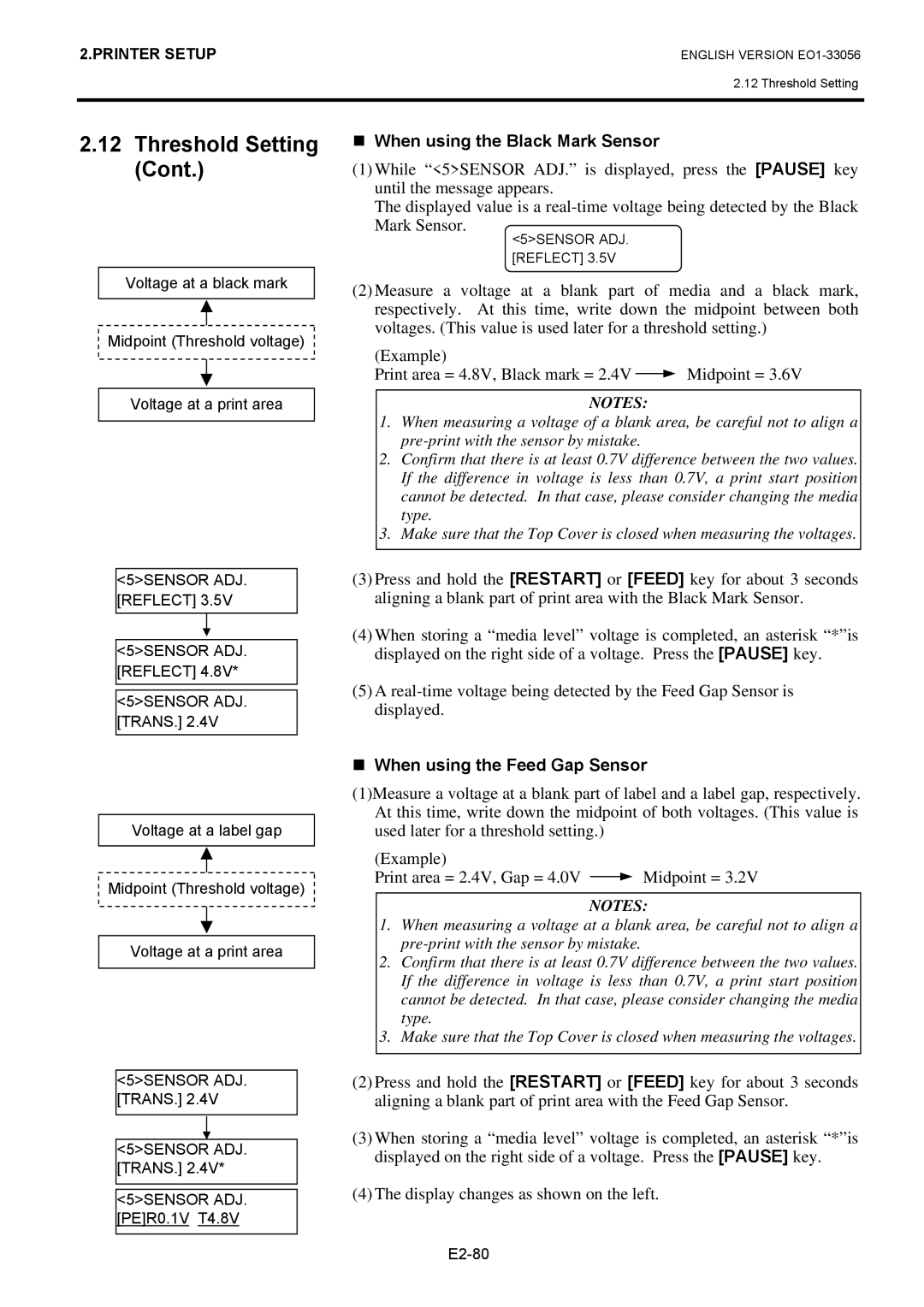

„ When using the Black Mark Sensor

„ When using the Feed Gap Sensor

„ Storing a No Media Level Voltage

„ Manual Threshold Setting

Press and hold the Restart or Feed key for about 3 seconds

THRESHOLDR4.0V THRESHOLDT4.0V THRESHOLDR3.9V

On Line Operation

Operation Panel

Operation

Reset

Press and hold the Restart key for 3 seconds or longer

When the Cutter Module is fitted

Maintenance

Cleaning

Print Head/Platen

Print Head/Platen Pinch Roller

Take out the Pinch Roller Ass’y from the printer

Plate with the Positioning Pins of the printer

Attach the Ribbon End Sensor Plate to the printer

Re-install the Media Guides using the screws

Covers and Panels

Remove the White Screw to detach the Media Guide

Optional Cutter Module

Remove jammed media, if any

Cutter Blade

Care must be taken not to pinch your fingers or hands

Error Messages

Troubleshooting

Restart key

Error Messages Problems/Cause

Possible Problems

Possible Problems Causes Solutions

Cutter blade is dirty Clean the cutter blade

Ribbon is not loaded properly Load the ribbon properly

Removing Jammed Media

Do not use any tool that may damage the Print Head

Removing Jammed Media

This section describes the printer specifications

Printer Specifications

Model

Available bar code types

Media Type

Supply Specifications

Media

Label

Label

Detection Area of the Transmissive Sensor

Tag paper with square holes

Detection Area of the Reflective Sensor

Effective Print Area

Recommended Media and Ribbon Types

Ribbon

Media type Description

Combination of Media and Ribbon

Care/Handling of Media and Ribbon

Ribbon type

Ribbon type Description

Symbols in the message

Appendix 1 Messages and Leds

Dhcp client is being initialized

When the Dhcp function is enabled

Base LAN Board is being initialised

Printer did not succeed in writing data

Following message appears

Appendix 2 Interface

Receive buffer 1M byte

Connector

PIN

Standard

Number of ports Power source Self power Connector Type B

Number of ports Connector RJ-45

LED status Link LED

Serial interface Option B-SA704-RS-QM-R

SX708-RFID-U2-EU-R

Wireless LAN Option B-SA704-WLAN-QM-R

Expansion I/O Interface Option B-SA704-IO-QM-R

When purchasing the power cord

Appendix 3 Power Cord

At least, 125% of the rated current of the product

Appendix 4 Print Samples

Appendix 4 Print Samples

EAN13+2 digits

Interleaved 2

JAN13, EAN13

EAN13+5 digits

Customer bar code

UPC-A+5 digits

Industrial 2

KIX Code

Appendix 5 Glossaries

Expansion I/O Interface

Media and ribbon

Device used to remove labels from the backing paper

USB Universal Serial Bus

Index

Power switch 2-3 Pre-printed media 78, A5-1 Print head 1-4

A3-1

Index

EO1-33056D