Installation

UPS LOCATION

Move your UPS over short distances using its wheels. NOTE: the wheels are not designed to provide

MOUNTING BRACKET INSTALLATION

DANGER!

RISK OF PRODUCT DAMAGE AND SERIOUS PERSONAL INJURY

The UPS System's wheels are not designed to provide

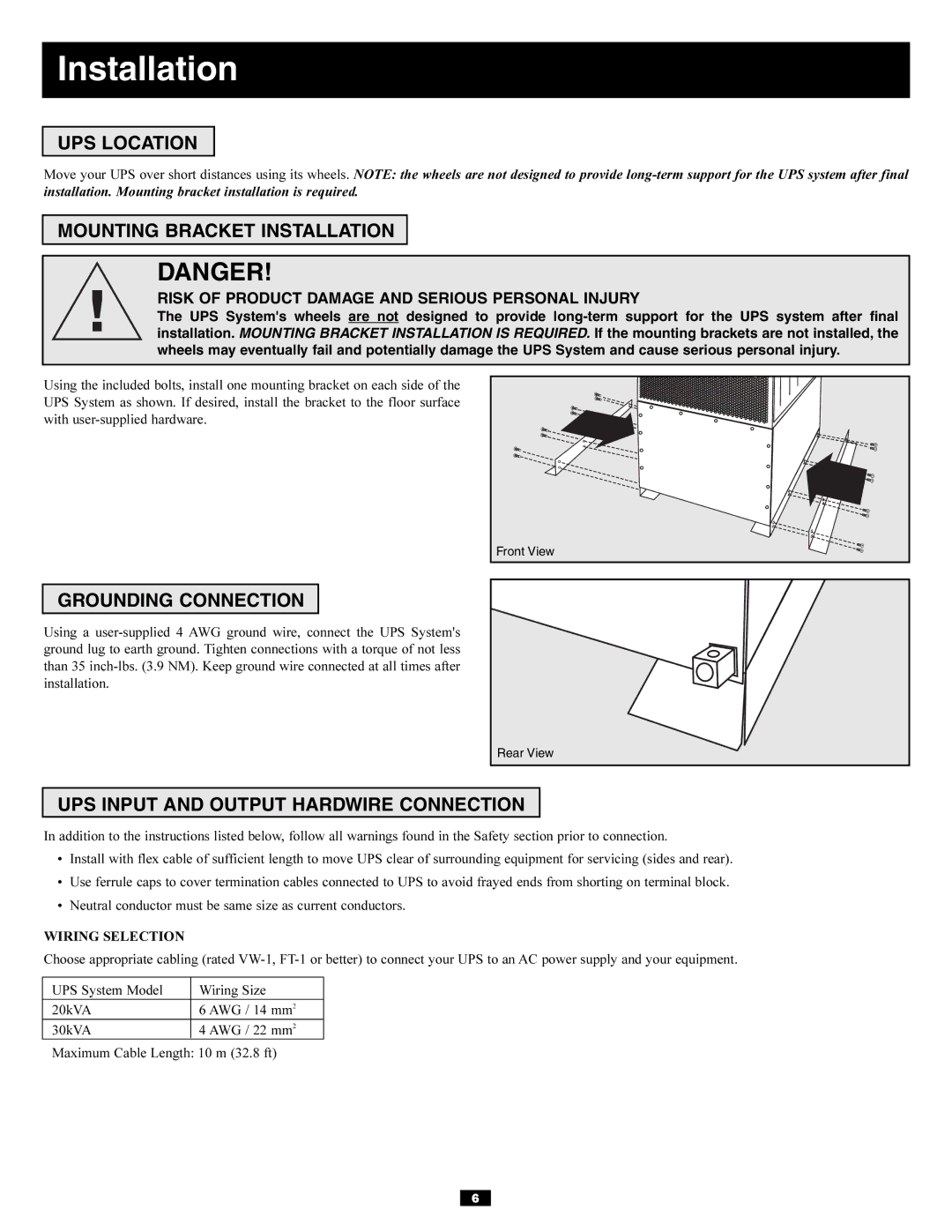

Using the included bolts, install one mounting bracket on each side of the UPS System as shown. If desired, install the bracket to the floor surface with

Front View |

GROUNDING CONNECTION

Using a

Rear View

UPS INPUT AND OUTPUT HARDWIRE CONNECTION

In addition to the instructions listed below, follow all warnings found in the Safety section prior to connection.

•Install with flex cable of sufficient length to move UPS clear of surrounding equipment for servicing (sides and rear).

•Use ferrule caps to cover termination cables connected to UPS to avoid frayed ends from shorting on terminal block.

•Neutral conductor must be same size as current conductors.

WIRING SELECTION

Choose appropriate cabling (rated

UPS System Model | Wiring Size |

20kVA | 6 AWG / 14 mm2 |

30kVA | 4 AWG / 22 mm2 |

Maximum Cable Length: 10 m (32.8 ft)

6