700T specifications

The Triumph Plant 700T is an impressive piece of machinery that has garnered attention in the realm of construction and heavy equipment. Recognized for its robust performance, this versatile plant embodies a blend of innovative technologies and practical features that make it stand out among its competitors.One of the key highlights of the Triumph Plant 700T is its powerful engine. Equipped with a high-efficiency diesel engine, the 700T ensures optimal performance even in the most demanding conditions. This engine not only provides excellent horsepower but also meets stringent emissions regulations, contributing to a more environmentally friendly operation. The advanced engine management system allows for fuel savings while maintaining outstanding productivity.

The 700T incorporates a cutting-edge hydraulic system, which enhances its lifting capabilities and overall performance. With a high-flow hydraulic pump, this plant is capable of handling a variety of tasks, from lifting heavy loads to precise positioning. The hydraulic system is designed for durability and efficiency, ensuring that operators can rely on consistent performance throughout the workday.

Ergonomics plays a significant role in the design of the Triumph Plant 700T. The operator cabin is spacious and thoughtfully laid out, providing a comfortable environment for long hours of operation. Equipped with user-friendly controls and intuitive dashboard displays, operators can easily monitor performance metrics and adjust settings as needed. The excellent visibility from the cabin enhances safety on the job site, allowing operators to remain aware of their surroundings.

Moreover, the Triumph Plant 700T features advanced safety systems designed to protect operators and personnel around the machine. These systems include stability monitors, emergency shutdown mechanisms, and various sensors that provide real-time feedback on the plant's operational status.

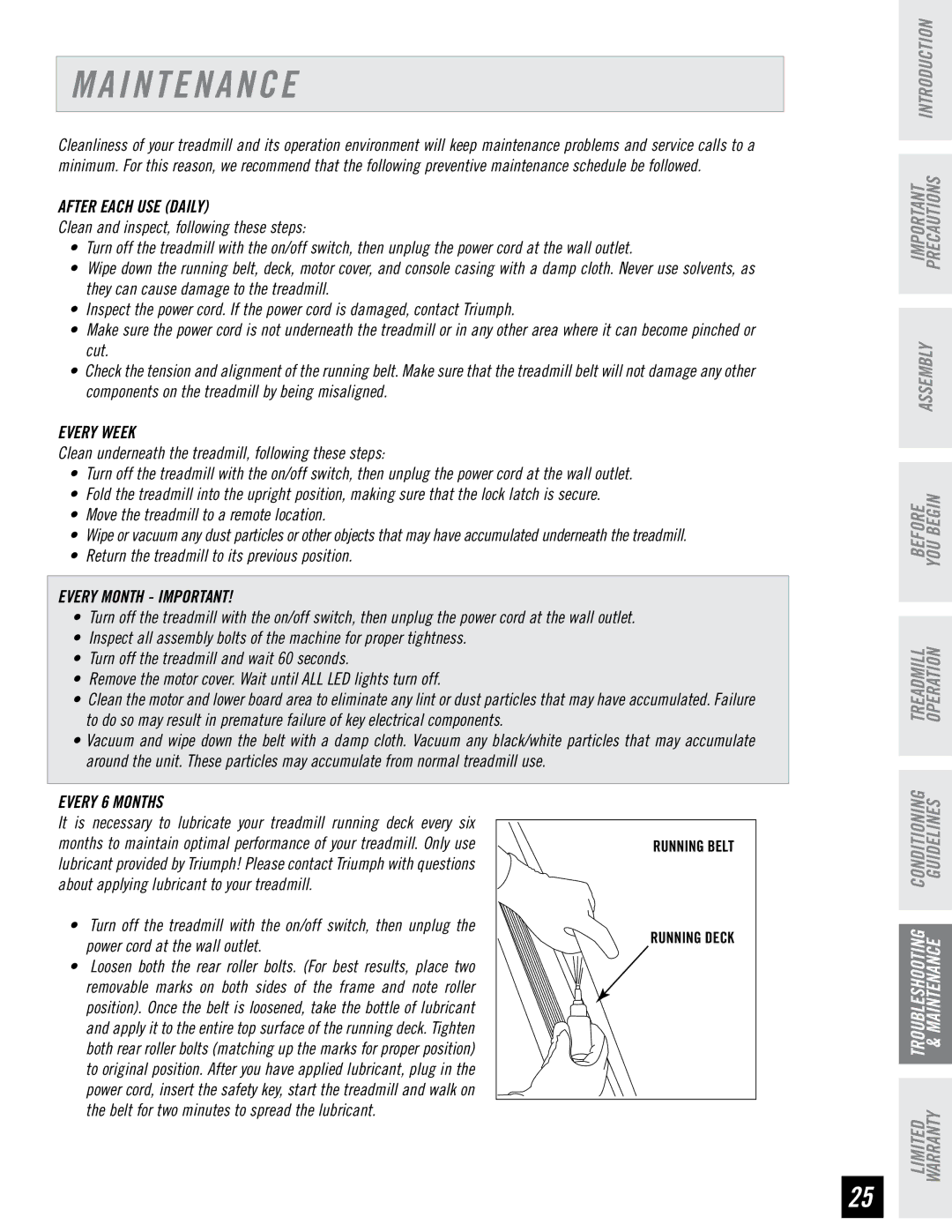

Maintenance has also been made easier with the 700T. Designed for quick access to essential components, routine checks and servicing can be performed efficiently, minimizing downtime. The robust construction of the machine ensures that it can withstand the rigors of tough working environments, making it a reliable choice for diverse projects.

In summary, the Triumph Plant 700T is a powerful, efficient, and user-friendly machine that exemplifies modern engineering. With its combination of a high-performance engine, advanced hydraulic systems, ergonomic design, and strong safety features, the 700T is an ideal solution for those seeking reliability and productivity in plant operations.