Section 5: Maintenance

WARNING Before inspecting, cleaning or servicing the unit, shut off engine, wait for all parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key on elec- tric start models. Failure to follow these instructions can result in serious personal injury or property damage.

Cutting Edge

of Tine

Figure 5-6: Removing single tine.

Cutting Edge

of Tine

Figure 5-7: Removing a tine assembly.

CHECKING AND ADJUSTING TENSION ON THE DRIVE BELTS

Maintaining correct belt tension is impor- tant to good tilling performance and long belt life. A loose belt will slip on the engine and transmission pulleys and cause the tines and wheels to slow down

–or stop – even though the engine is running at full speed. A loose belt will also result in premature belt wear.

While checking belt tension, also check for cracks, cuts or frayed edges. A belt that is in poor condition should be replaced.

The tension on a new forward drive belt (I, Figure

Thereafter, check the tension after every ten (10) hours of operation.

The reverse drive belt (J, Figure

adjustment until a significant number of operating hours has passed. A tension adjustment is required only if there is no reverse action when the Reverse Clutch Control knob is pulled out.

To Check and Adjust Tension on the Forward Drive Belt

WARNING

Follow the belt adjustment instructions carefully. An incorrect adjustment could result in the Forward Clutch mechanism engaging too soon. This could cause loss of tiller control and result in per- sonal injury or property damage.

1.The check for correct belt tension is the same as that described in item 5 of “Step 4: Attach Forward Clutch Rod” on page 8. Before performing this check, shut off the engine, disconnect the spark plug wire, remove the ignition key on electric start models, and allow the engine and muffler to cool down. If, after following the adjustment procedures you cannot get the correct gap on the forward clutch rod adjustment bracket, you will need to make a secondary adjustment as described next.

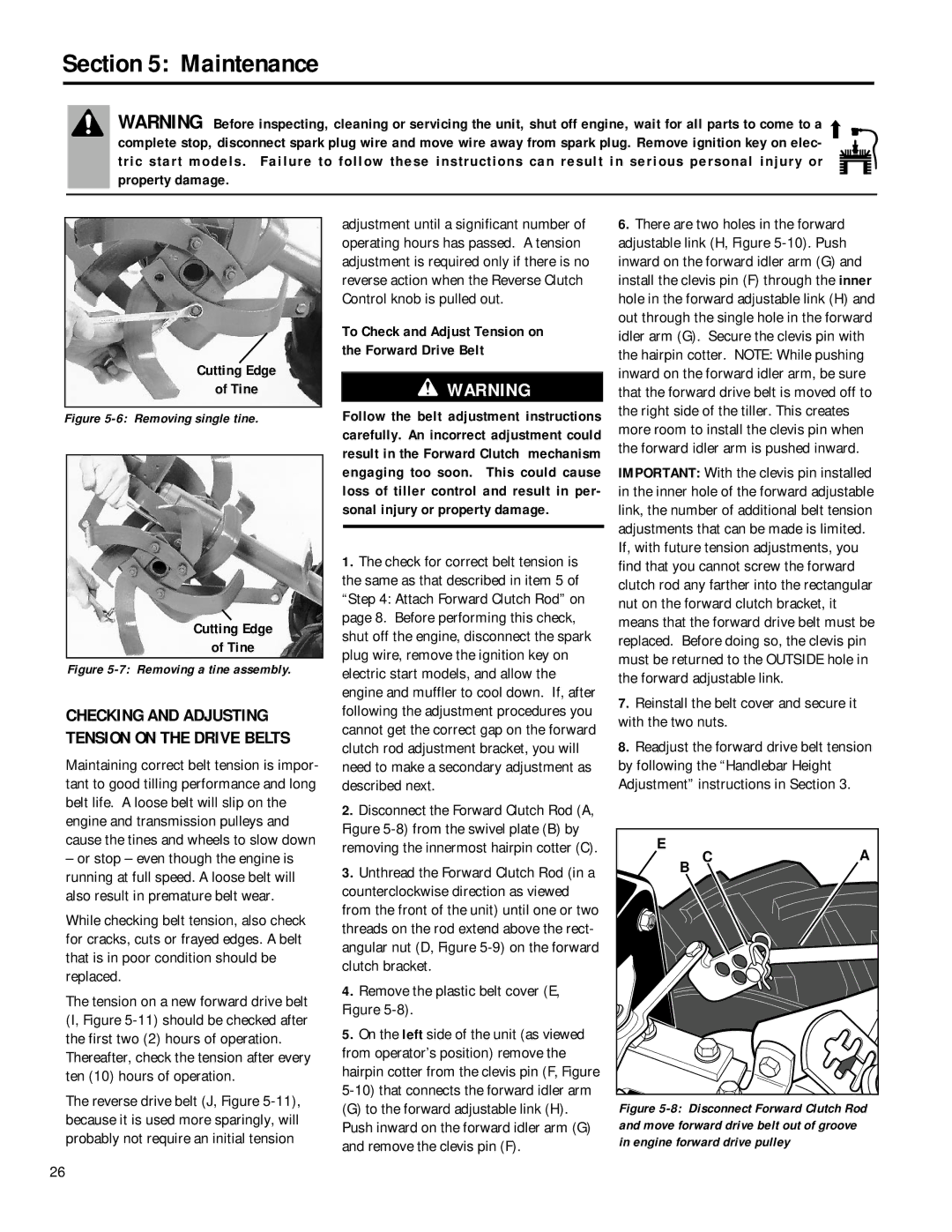

2.Disconnect the Forward Clutch Rod (A, Figure

3.Unthread the Forward Clutch Rod (in a counterclockwise direction as viewed from the front of the unit) until one or two threads on the rod extend above the rect- angular nut (D, Figure

4.Remove the plastic belt cover (E, Figure

5.On the left side of the unit (as viewed from operator’s position) remove the hairpin cotter from the clevis pin (F, Figure

(G) to the forward adjustable link (H). Push inward on the forward idler arm (G) and remove the clevis pin (F).

6.There are two holes in the forward adjustable link (H, Figure

IMPORTANT: With the clevis pin installed in the inner hole of the forward adjustable link, the number of additional belt tension adjustments that can be made is limited.

If, with future tension adjustments, you find that you cannot screw the forward clutch rod any farther into the rectangular nut on the forward clutch bracket, it means that the forward drive belt must be replaced. Before doing so, the clevis pin must be returned to the OUTSIDE hole in the forward adjustable link.

7.Reinstall the belt cover and secure it with the two nuts.

8.Readjust the forward drive belt tension by following the “Handlebar Height Adjustment” instructions in Section 3.

E | C | A | |

B | |||

|

Figure 5-8: Disconnect Forward Clutch Rod and move forward drive belt out of groove in engine forward drive pulley

26