IMPORTANT INFORMATION FOR ALL

CONNECTOR PIPES

The connector pipe must be constructed and installed so that it maintains clearances, keeps condensation and creosote within the pipe, and is capable of withstanding a 2100°F degree chimney fire.

1.The connector pipe should slant down toward the fur- nace a minimum of 1/4” to the foot. At no time should the pipe turn downward toward the chimney or run horizontal.

2.There should be no more than two 90 degree elbows.

3.The connector pipe should never be longer than six feet. If it is absolutely necessary to make a run of more than six feet (not recommended) use extra support brackets every 3 feet.

4.The connector pipe should never be reduced to a smaller size than flue opening on the furnace.

5.The connector pipe should not block the flue of the chimney or extend into it in any way.

6.A good airtight thimble should be used to hold the con- nector pipe in the chimney. It should be constructed so the connector pipe can be removed for cleaning.

7.The connector pipe should not leave the heated por- tion of the building to reach the chimney.

8.The connector pipe should not pass from one story to the next before entering the chimney, nor should it pass through any closed or enclosed space.

9.The connector pipe and any elbows must be of 24 gauge or greater.

10.The connector pipe should not be located near or in a walk way or well traveled area.

11.All male ends of connector pipe should run or point towards the furnace.

12.Install a cast iron adjustable damper in the first joint of the connector pipe, nearest to the flue collar.

DAMPERS ON STOVE PIPES

When burning coal, we recommend a Barometric Draft Damper be installed at a safe convenient place between chimney and your furnace preferably less than 3’ from the flue collar.

When you have installed the connector pipe between your furnace and the chimney, tap the pipe hard with your fingernail. Remember the sound it makes - it will be a “ting” echoing inside the stove pipe. If later you tap and hear a muffled thud, you are building up soot in the pipe and should clean it. This pipe should be cleaned at least once or twice during the heating season.

DO NOT CONNECT TWO HEATERS TO THE SAME CHIMNEY FLUE. The National Fire Prevention Association recommends that wood burning appliances vent into a separate flue from gas or oil furnaces. If such an installation is contemplated, first check with a local building inspector to find out if a separate flue for a wood burner is required.

Use of a Barometric Draft Control (when burning wood) is recommended ONLY in the event your chimney creates excessive draft leading to an over-firing condition.

HEATED AIR DISCHARGE

The Clayton furnace is designed for use as a supplemental heating source. When used as a supplementary furnace, the 1602/1802 is connected in conjunction with an oil, gas, or electric furnace to the existing duct work which distributes the heated air into several rooms and/or areas.

Though United States Stove Company expressly Does Not recommend the use of its furnaces to be installed and/or used as a free-standing heater, it is possible to achieve a reasonably safe and functional installation IF certain stan- dard procedures are followed. The following are guidelines only and are intended to enable the furnace user to obtain reasonable efficiency from his furnace, and with due re- spect to safety when installing as a “free-standing heater”. If installed correctly, and in accordance with the instructions found in this manual, your warm air furnace may be installed as a “space heater” within living quarters, cabins, garage, or workshop. Please adhere to the following:

1.The use of a cold air return and/or filter box is mandatory. This will not only increase your blower life and provide filtered air, it will also help prevent the blower or blowers from “capturing” heated air exiting from the top of the furnace heat outlets.

2.If installed as purchased , without directing the heat away from the furnace itself, it will simply sit and cycle, turning the blowers off and on. The thermostat may not function properly.

3.All larger furnaces (or those with multi-speed blowers) absolutely require BACK PRESSURE to prevent premature motor winding failure. If allowed to operate at high RPM (As in “FREE AIR” mode - no duct work or flow restrictions) the windings overheat, insulation melts and the motor simply burns up - not covered under warranty.

CONNECTING HOT AIR DUCT

TO FURNACE

We strongly recommend that the hot air duct work be installed by a home heating specialist. If doing the instal- lation yourself, before you decide which installation will best suit your needs, consult a qualified heating technician and follow his recommendations as to the safest and most efficient method of installation.

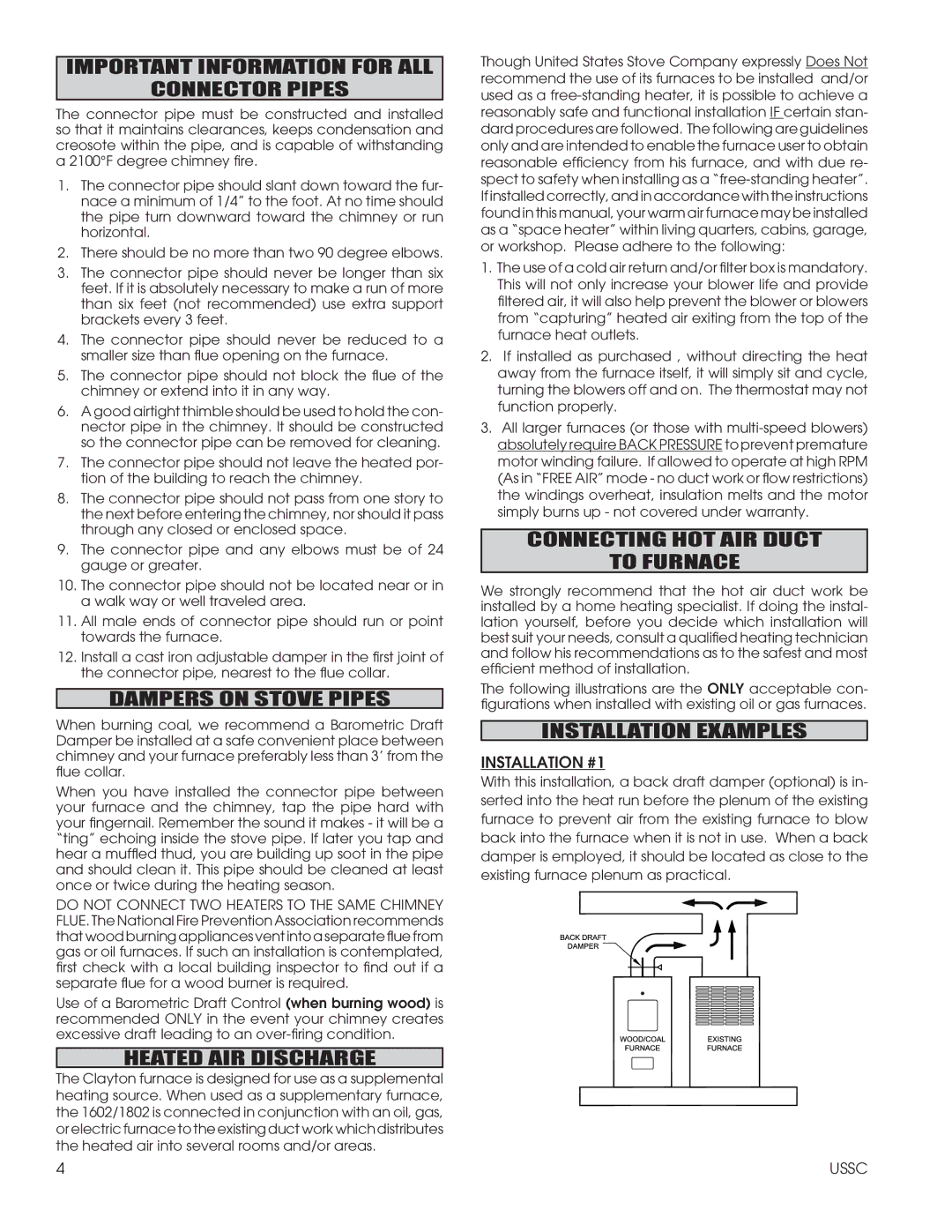

The following illustrations are the ONLY acceptable con- figurations when installed with existing oil or gas furnaces.

INSTALLATION EXAMPLES

INSTALLATION #1

With this installation, a back draft damper (optional) is in- serted into the heat run before the plenum of the existing furnace to prevent air from the existing furnace to blow back into the furnace when it is not in use. When a back damper is employed, it should be located as close to the existing furnace plenum as practical.